Tail water recovery device for producing magnesium by concentrated nitric acid

A recovery device and technology of magnesium tail water, applied in heating water/sewage treatment, gaseous discharge wastewater treatment, dispersed particle separation, etc. The effect of reducing nitric acid concentration, low treatment cost and achieving neutral emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

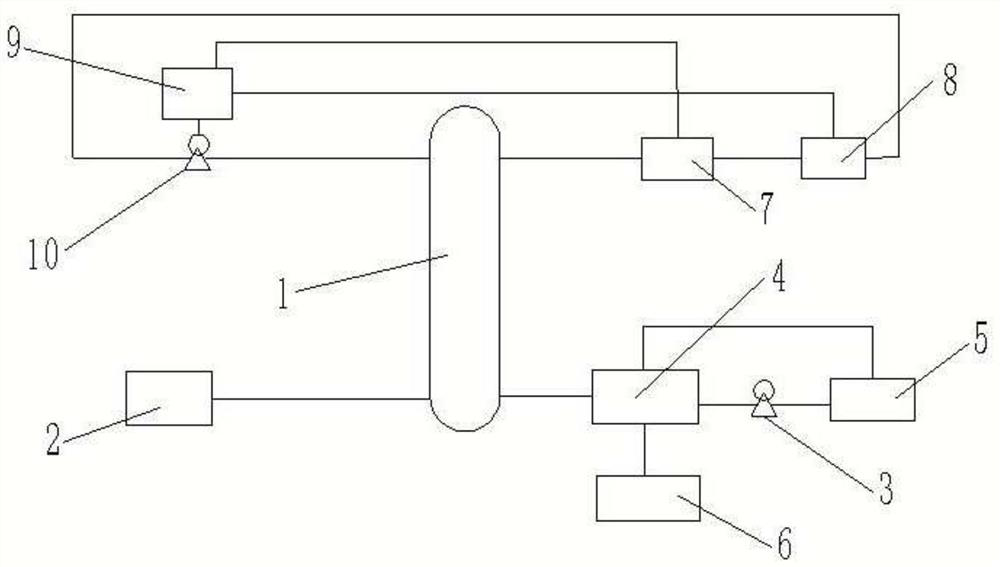

[0016] like figure 1 Shown, comprise acid water distillation tower 1, the bottom of acid water distillation tower 1 is connected with magnesium nitrate evaporator 2, and acid water distillation tower 1 is connected with magnesium tail circulation mechanism and tower tail circulation mechanism;

[0017] The magnesium tail circulation mechanism includes a magnesium tail water circulation tank 9 communicated with the acid water distillation tower 1 through a magnesium tail water circulation pump 10;

[0018] The tower tail circulation mechanism includes a tower tail water circulation tank 4 connected to the tower tail of the acid water distillation tower 1, the tower tail water circulation tank 4 is connected with the inlet of the tower tail injector 5 through the tower tail pump 3, and the outlet of the tower tail injector 5 is connected to the tower tail water circulation tank 4, and the tower tail water circulation tank 4 is connected to the tower tail water circulation tank 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com