Surface burr removing device for mobile phone cover plate production and processing

A technology for removing burrs and mobile phone covers, which is applied in the direction of grinding drive devices, metal processing equipment, grinding/polishing safety devices, etc. Market application value, reduce labor intensity, and ensure the effect of production and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

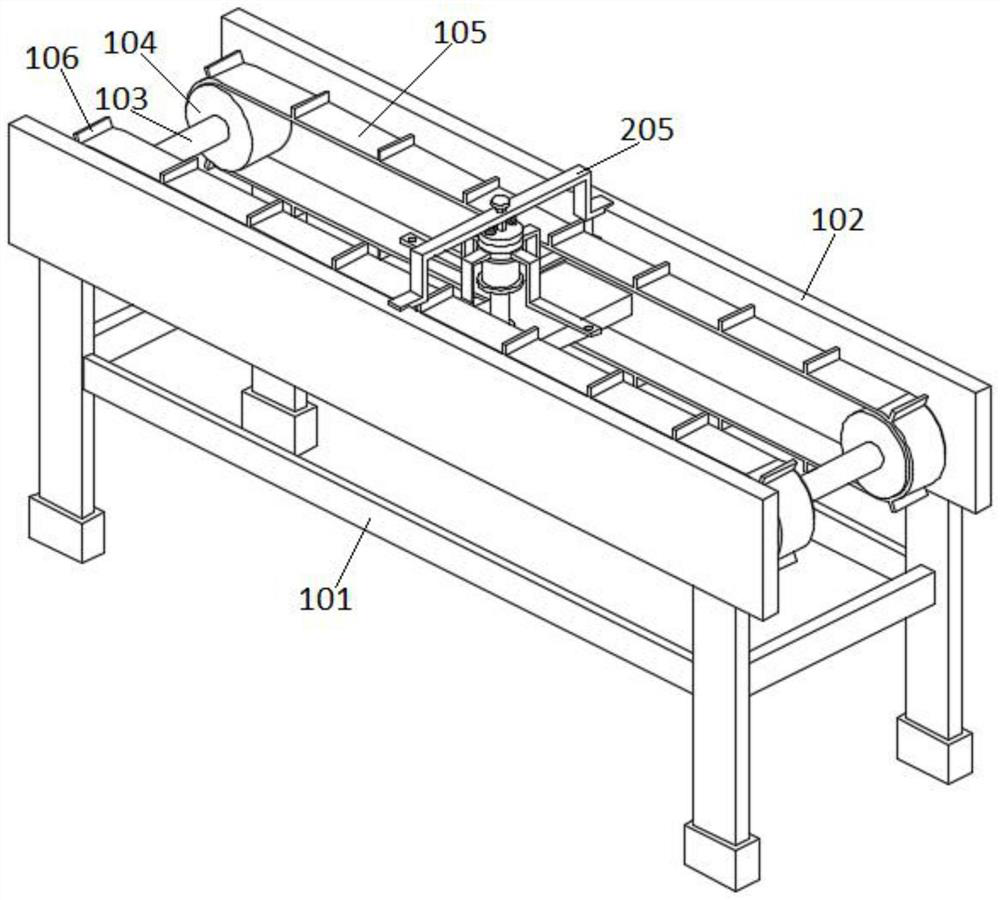

specific Embodiment 1

[0033] see figure 1 As shown, the present invention is a surface deburring device for the production and processing of mobile phone cover plates, including a feeding assembly 1; a clamping assembly 2 is installed on the feeding assembly 1; a shifting assembly 3 is installed above the clamping assembly 2 ; The shift assembly 3 is equipped with a grinding machine 4; the grinding machine 4 has a conventional grinding disc 401 in this field. A plurality of mobile phone covers are conveyed side by side through the feeding assembly 1, and a mobile phone cover is lifted from the feeding assembly 1 by the clamping assembly 2 to clamp the mobile phone cover, and finally the shifting assembly 3 is used to drive the grinder 4. Horizontal movement or up and down movement realizes the grinding of the mobile phone cover plate on the clamping assembly 2, which not only effectively improves the deburring efficiency and effect of the mobile phone cover plate, but also reduces the labor intensi...

specific Embodiment 2

[0035] On the basis of the specific embodiment 1, the difference of this embodiment lies in:

[0036] Such as Figure 2-3As shown, the feeding assembly 1 includes a conventional frame 101 in the art; a pair of side support beams 102 are fixed side by side on the top of the frame 101; a pair of drive shafts 103 arranged side by side are rotated between the support beams 102 on both sides; A pair of pulleys 104 are axially fixed on the shaft 103; two pulleys 104 on the same side are connected through a synchronous belt 105; the working surface of the synchronous belt 105 is fixed with a plurality of spacers 106 side by side along the length direction; a drive The output shaft of the shaft 103 is coaxially connected to an intermittent drive assembly; the intermittent drive assembly is composed of a conventional stepping motor and a sheave mechanism in the field, which belongs to the prior art and will not be repeated here. During use, the mobile phone cover is placed on the work...

specific Embodiment 3

[0038] On the basis of the second embodiment, the difference of this embodiment is:

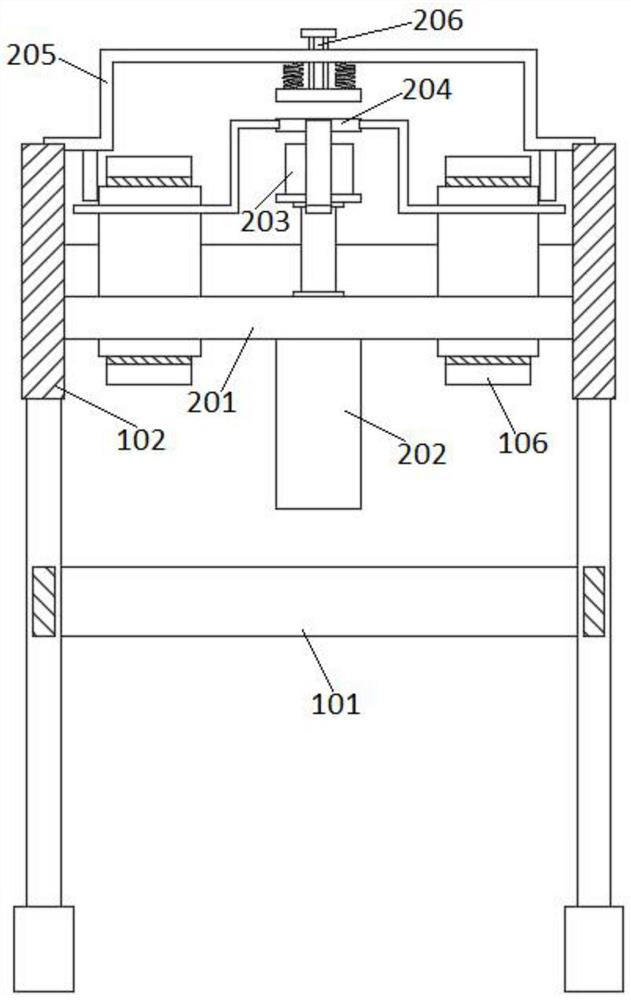

[0039] Such as Figure 2-4 As shown, the clamping assembly 2 includes a support plate 201 horizontally fixed between the support beams 102 on both sides; a conventional hydraulic cylinder 202 in this field is vertically fixed on the support plate 201; the output end of the hydraulic cylinder 202 is vertically fixed with a second A drive motor 203; the connecting structure between the first drive motor 203 and the hydraulic cylinder 202 belongs to the conventional design in the art; the output shaft of the first drive motor 203 is horizontally fixed with a first clamping disc 204; the first clamping disc 204 The top of the suspension beam 205 is provided with; the suspension beam 205 is fixedly erected on the support beams 102 on both sides; the suspension beam 205 slides and intersperses with a vertically arranged guide rod 206; the horizontal cross section of the guide rod 206 is a regular h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com