5G optical module PCB punching device capable of adjusting drilling size

A drilling device and optical module technology, applied in metal processing, etc., can solve the problems affecting production efficiency, unable to change the drilling aperture independently, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

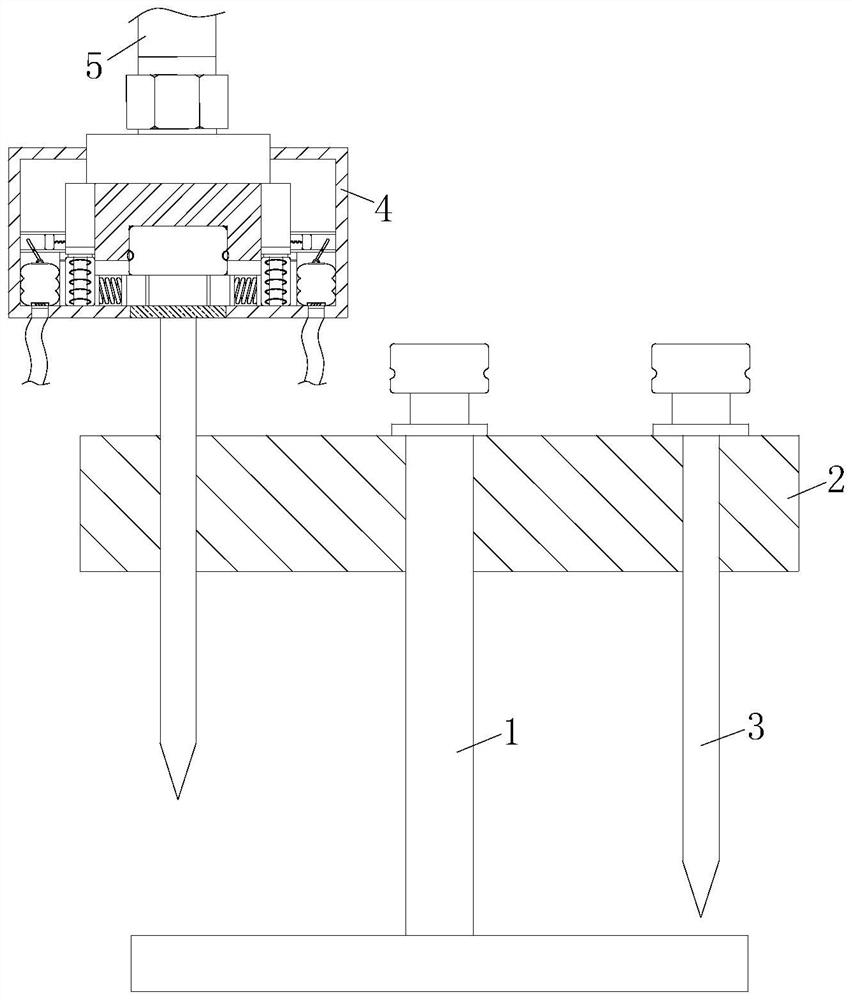

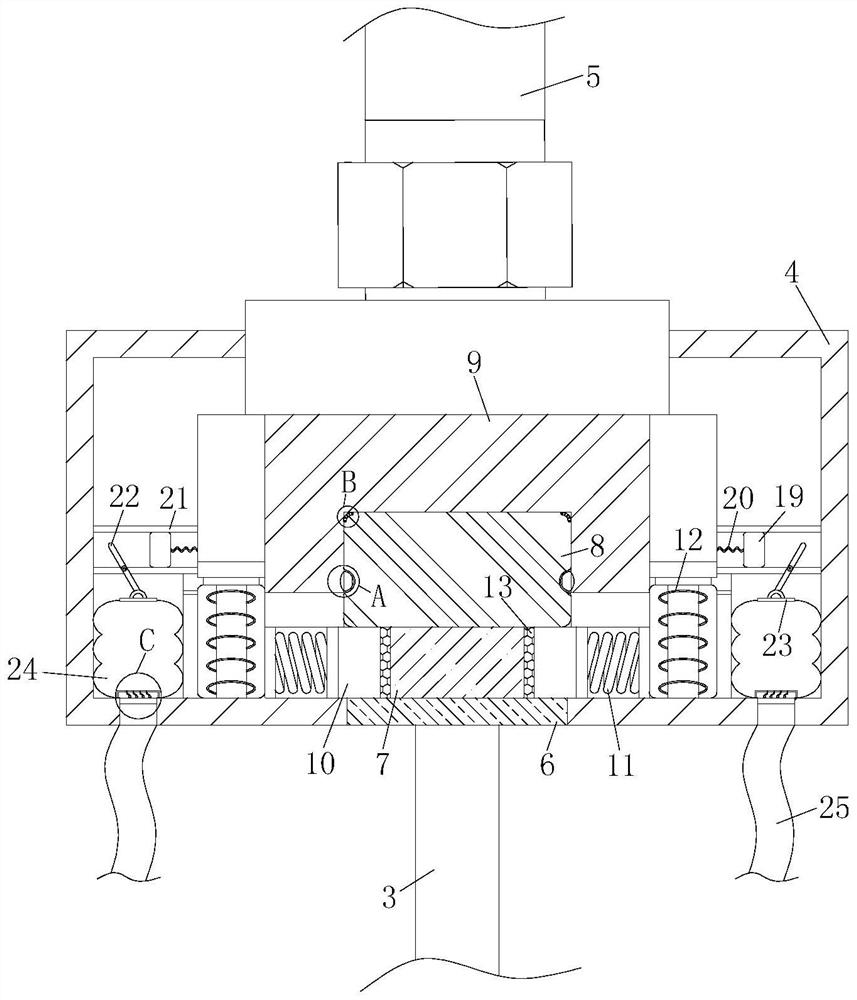

[0030] Such as Figure 1 to Figure 2 As shown, a 5G optical module PCB drilling device for adjusting the drilling size described in the embodiment of the present invention includes a rotating shaft 1, and a mounting plate 2 is fixed on the upper end of the rotating shaft 1, and the mounting plate 2 is connected internally. There are multiple groups of drill bits 3, and the diameters of the multiple groups of drill bits 3 are not equal. A fastening housing 4 is arranged above the drill bits 3, and a transmission rod 5 is fixed on the upper end of the fastening housing 4; during work, the servo The drive module will drive the transmission rod 5 to rotate, and the rotating shaft 1 rotates to drive the fastening housing 4 to rotate, and the fastening housing 4 rotates to drive the drill bit 3 to rotate to drill the PCB. When the drilling size needs to be adjusted, this In this case, data equipment is required to drive the transmission rod 5 to the top of the rotating shaft 1, then...

Embodiment 2

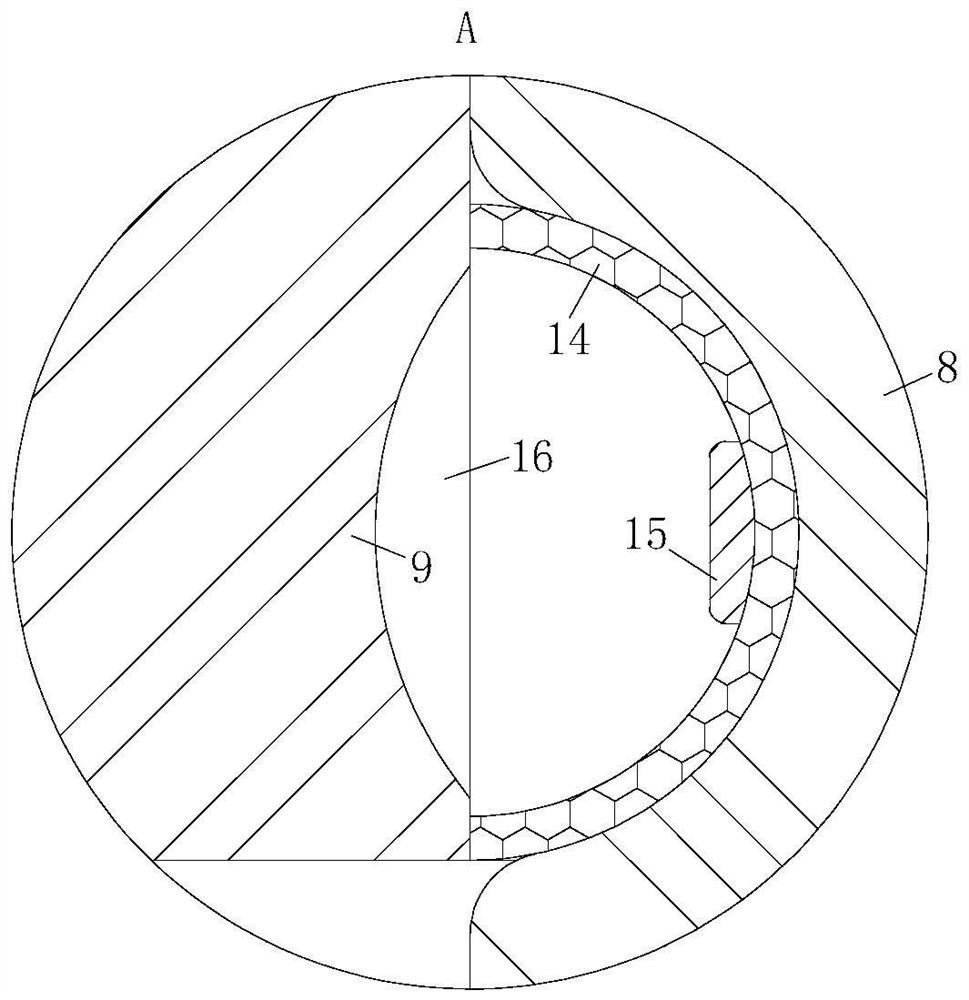

[0040] Such as Figure 6 to Figure 7 As shown in Comparative Example 1, another embodiment of the present invention is: a detection contact 29 is slidably connected to the top of the clamping block 8, and a detection contact 29 is fixed between the detection contact 29 and the clamping block 8. A spring 31, a circuit contact 30 is arranged above the detection contact 29, and the circuit contact 30 is fixedly connected to the connecting block 9; during operation, during the installation of the clamping block 8, it will simultaneously drive its internal The detection contact 29 is in contact with the circuit contact 30, and the setting of the detection spring 31 can make buffering during the contact process, and also makes the detection contact 29 contact with the circuit contact 30 more closely after the installation is completed, and different The detection contact 29 on the drill bit 3 is different to the signals transmitted by the system, thereby facilitating the system to j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com