Vibrating feeder with good vibrating effect for ore processing

A vibrating feeder and vibrating feeding technology, which is applied to vibrating conveyors, conveyors, conveyor objects, etc., can solve problems such as low service life and frequent maintenance of vibrating motors, and achieve reduced maintenance, good vibration effect, and convenience The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

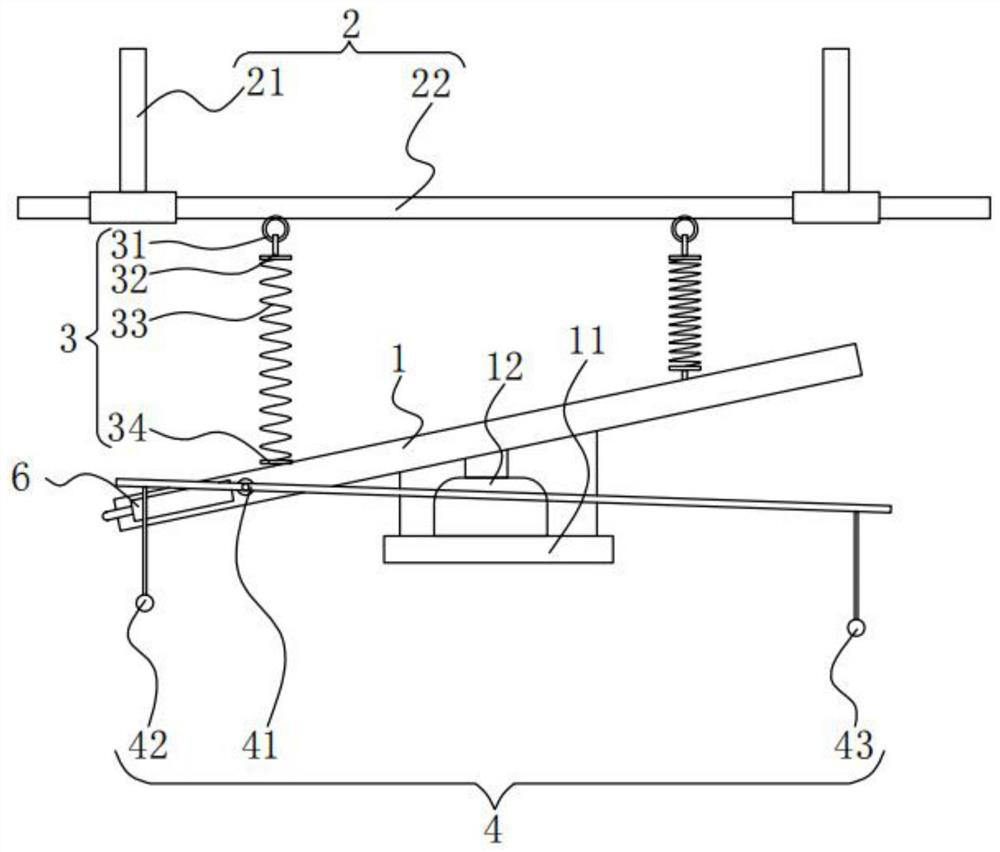

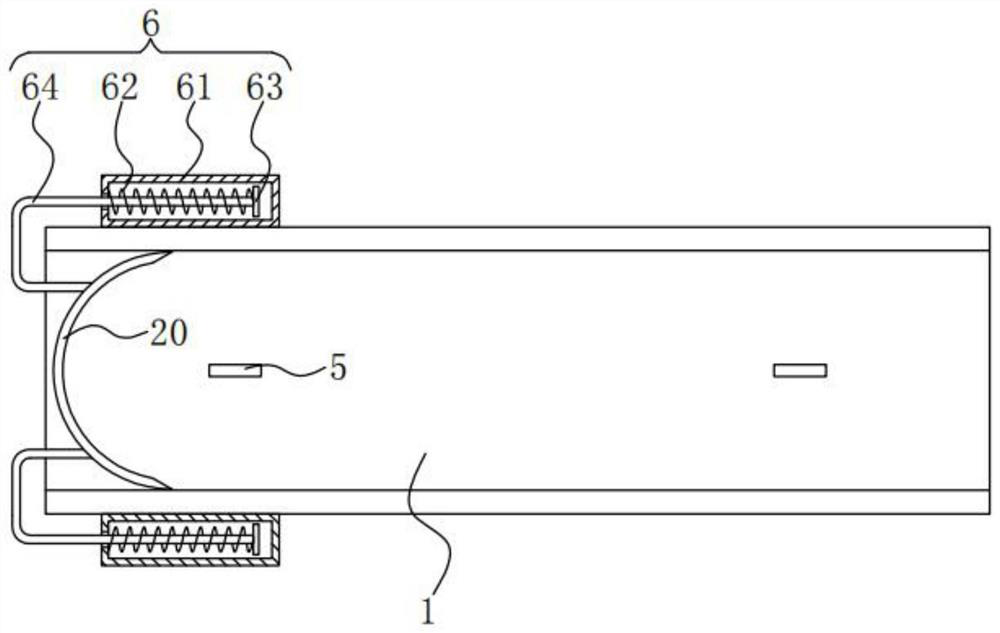

[0030] Please refer to figure 1 , figure 2 ,in, figure 1 The structure diagram of the first embodiment of the vibrating feeder for ore processing with good vibration effect provided by the present invention; figure 2 for figure 1 The structural schematic diagram of the top view part of the vibrating feeding plate shown. The vibrating feeder for ore processing with a good vibration effect includes: a vibrating feeding plate 1 and a mounting part 2, the mounting part 2 includes two installation hanging rods 21, and the bottom of the installation hanging rods 21 is fixedly connected with a horizontally arranged Cross bar 22 is installed, described vibrating feeding plate 1 is fixedly connected with support frame 11, and described supporting frame 11 is fixedly connected with vibrating motor 12 for driving described vibrating feeding plate 1 to vibrate;

[0031] Suspension device 3, described suspension device 3 is fixed on the bottom of described installation hanging rod 21...

no. 2 example

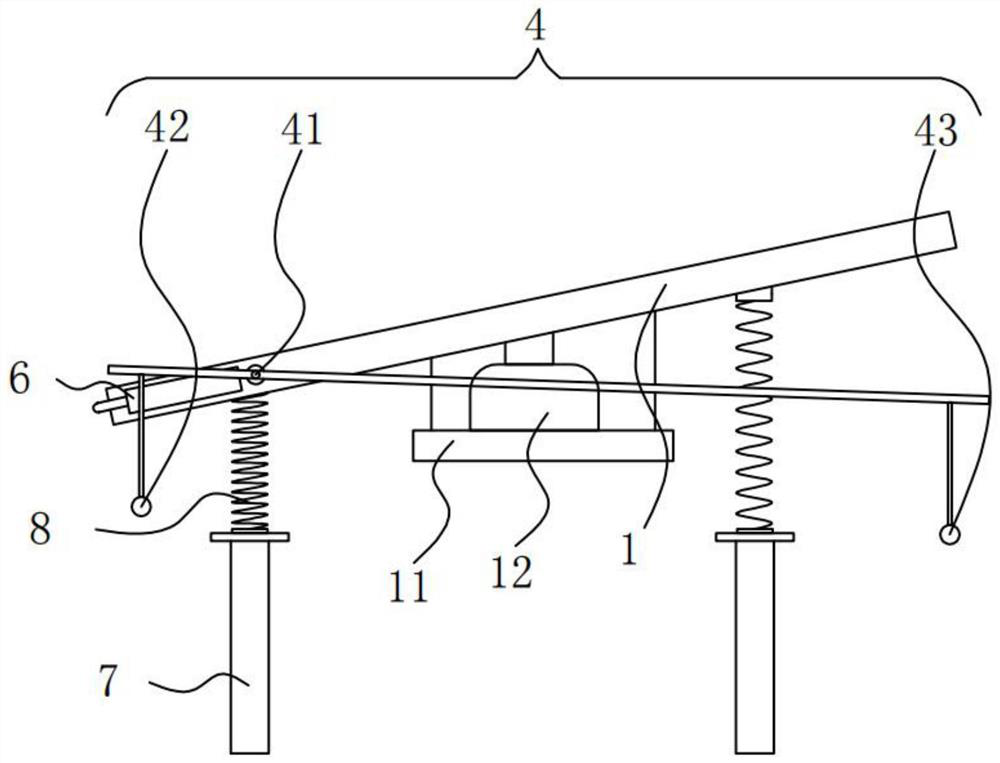

[0052] Please refer to Figure 4 with Figure 5 , Based on the vibration feeder for ore processing with good vibration effect provided in the first embodiment of the application, the second embodiment of the application proposes another vibration feeder for ore processing with good vibration effect. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0053] Specifically, the difference between the vibrating feeder for ore processing based on the good vibration effect provided by the second embodiment of the present application is that the vibrating feeder for ore processing based on the good vibration effect also includes

[0054] Support column 7, described support column 7 is arranged on the below of described vibration feeding plate 1, and the top of described support column 7 is fixedly connected with compression spring 8, and the t...

no. 3 example

[0058] Please refer to Figure 4 with Figure 5 , Based on the vibration feeder for ore processing with good vibration effect provided in the first embodiment of the application, the third embodiment of the application proposes another vibration feeder for ore processing with good vibration effect. The third embodiment is only a preferred mode of the first embodiment, and the implementation of the third embodiment will not affect the independent implementation of the first embodiment.

[0059] Specifically, the difference between the vibratory feeder for ore processing based on the good vibration effect provided by the third embodiment of the present application is that the vibratory feeder for ore processing based on the good vibration effect also includes

[0060] U-shaped bracket 9, the U-shaped bracket 9 is fixed on the bottom of the installation hanging rod 21, the top of the U-shaped bracket 9 is fixedly connected with a threaded sleeve 10, and the installation cross ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com