Construction method of concrete column

A concrete column and construction method technology, applied in the field of construction engineering, can solve the problems of honeycomb, pockmarked surface, large concrete free drop, soft conduit detached from the pump port, etc. on the surface of the concrete column, so as to improve the construction quality and slump Large, fluid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present embodiment provides a kind of construction method of concrete column, comprises the following steps:

[0040] S1. Concrete column 10 as a steel structure and formwork structure.

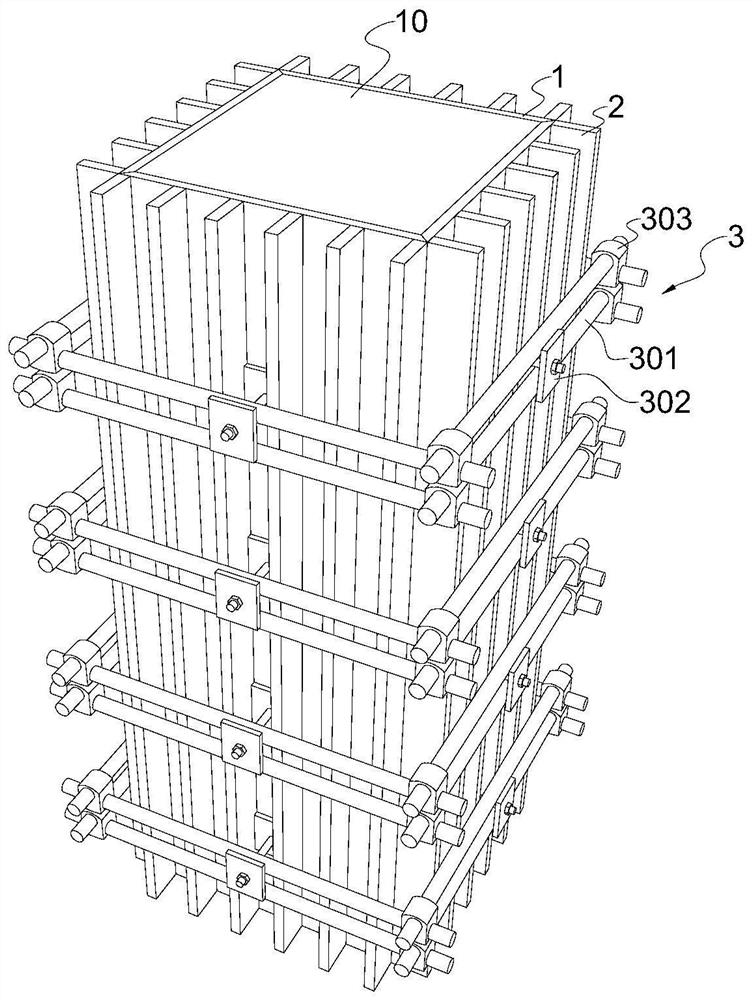

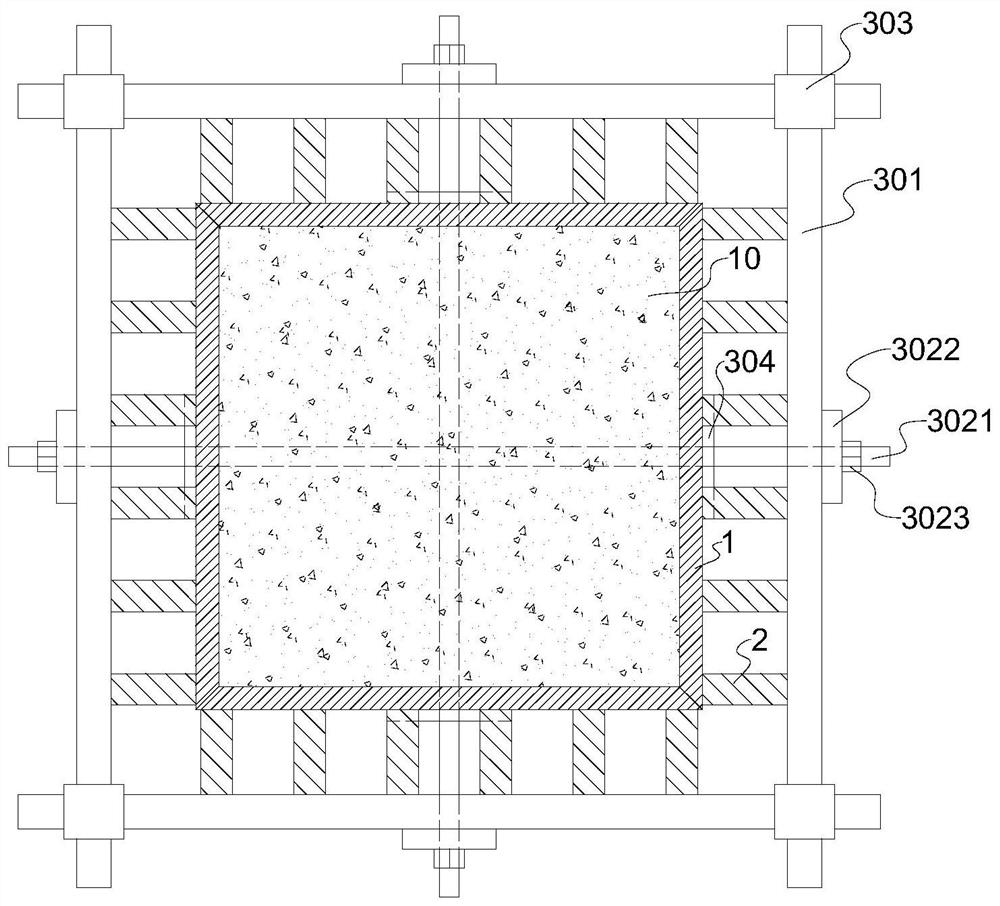

[0041] The reinforcement structure inside the concrete column 10 can be constructed according to the design requirements, and details will not be repeated here. Please refer to figure 1 and figure 2 , the formwork structure of the concrete column 10 includes a side formwork 1 , a vertical back flute 2 and a lateral restraint unit 3 .

[0042] Wherein, the side formwork 1 corresponds to the side wall of the concrete column 10 one by one, thereby relying on a plurality of side formworks 1 to form a molding cavity for pouring the concrete column 10; at the same time, the vertical back flute 2 is arranged on the outside of the side formwork 1, each There are a plurality of vertical back flutes 2 arranged on the outside of the side formwork 1, and the plurality of vertical back flut...

Embodiment 2

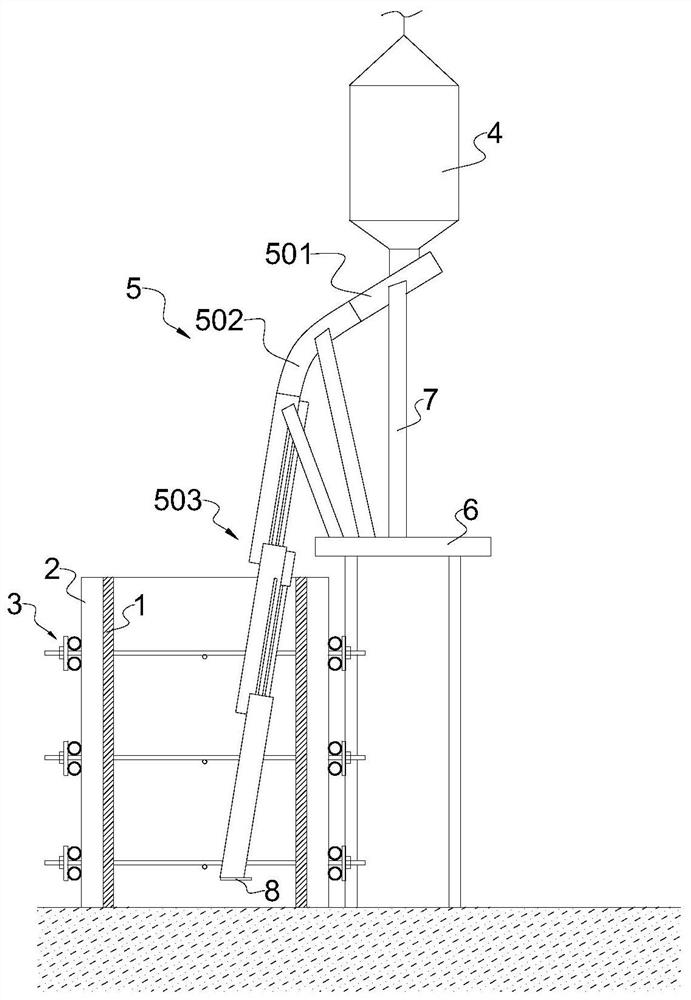

[0066] On the basis of Embodiment 1, considering that in the actual pouring process, as the pouring process continues to advance, the concrete surface in the formwork structure of the concrete column 10 will become higher and higher. If a conventional chute 5 is set, it will need to be constantly adjusted and adjusted. The whole process of changing the position of the chute 5 so that the chute 5 rises with the rise of the concrete surface in the formwork structure of the concrete column 10 is very cumbersome and time-consuming. For this reason, the difference between this embodiment and Embodiment 1 is that the chute 5 used in step S3 is designed as a scalable structure, so as to adapt to the height of the concrete surface of the formwork structure of the concrete column 10 .

[0067] Specifically, please refer to image 3 , the chute 5 is composed of an inclined section 501 , an arc transition section 502 and a telescopic section 503 connected in sequence. Wherein, the incli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com