Anti-segregation device for cement stabilized macadam mixing station

A cement-stabilized gravel and anti-segregation technology, which is applied in roads, road repairs, roads, etc., can solve problems affecting the space utilization of the discharge bin, and achieve the effects of improving space utilization, preventing segregation, and preventing concentrated accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

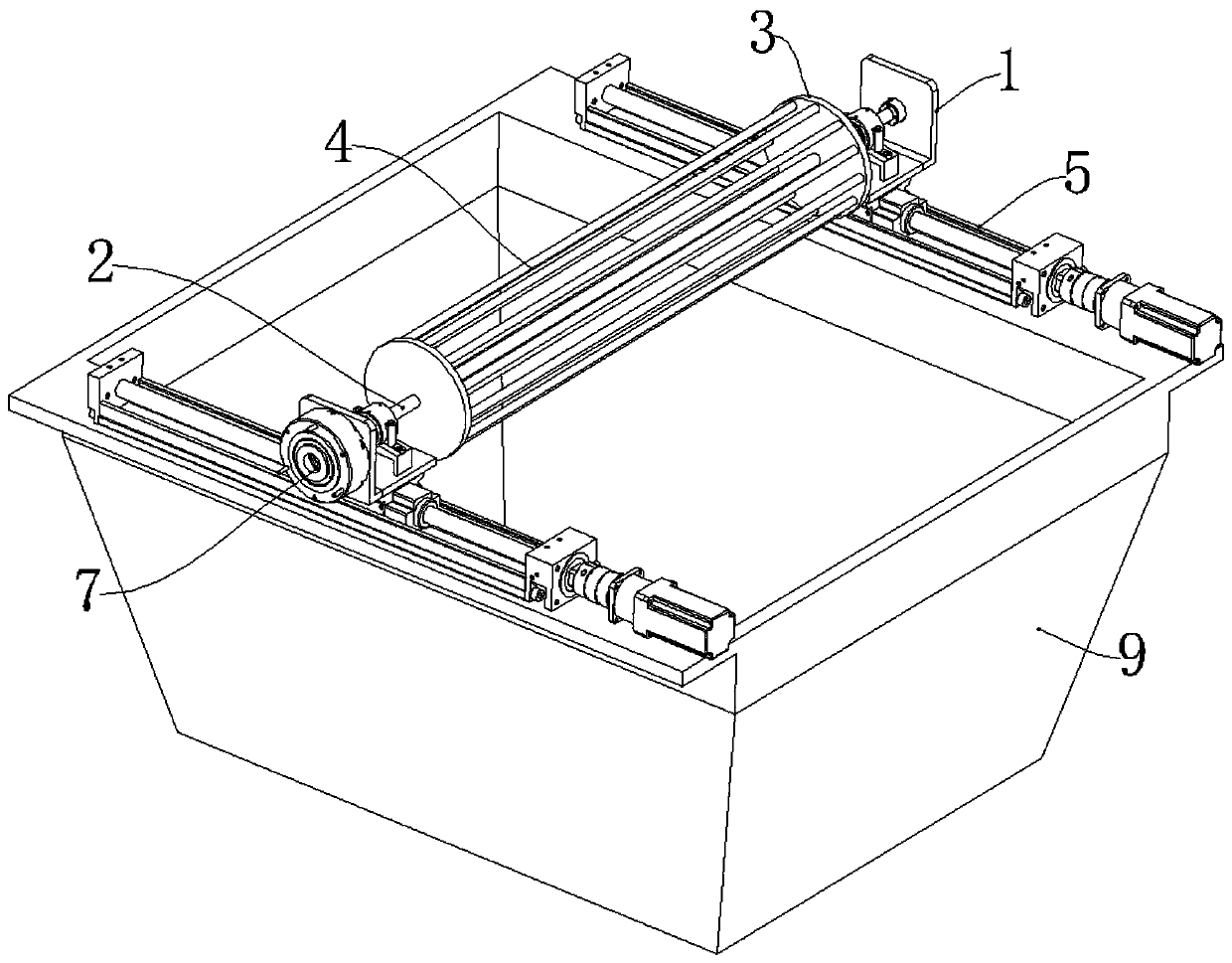

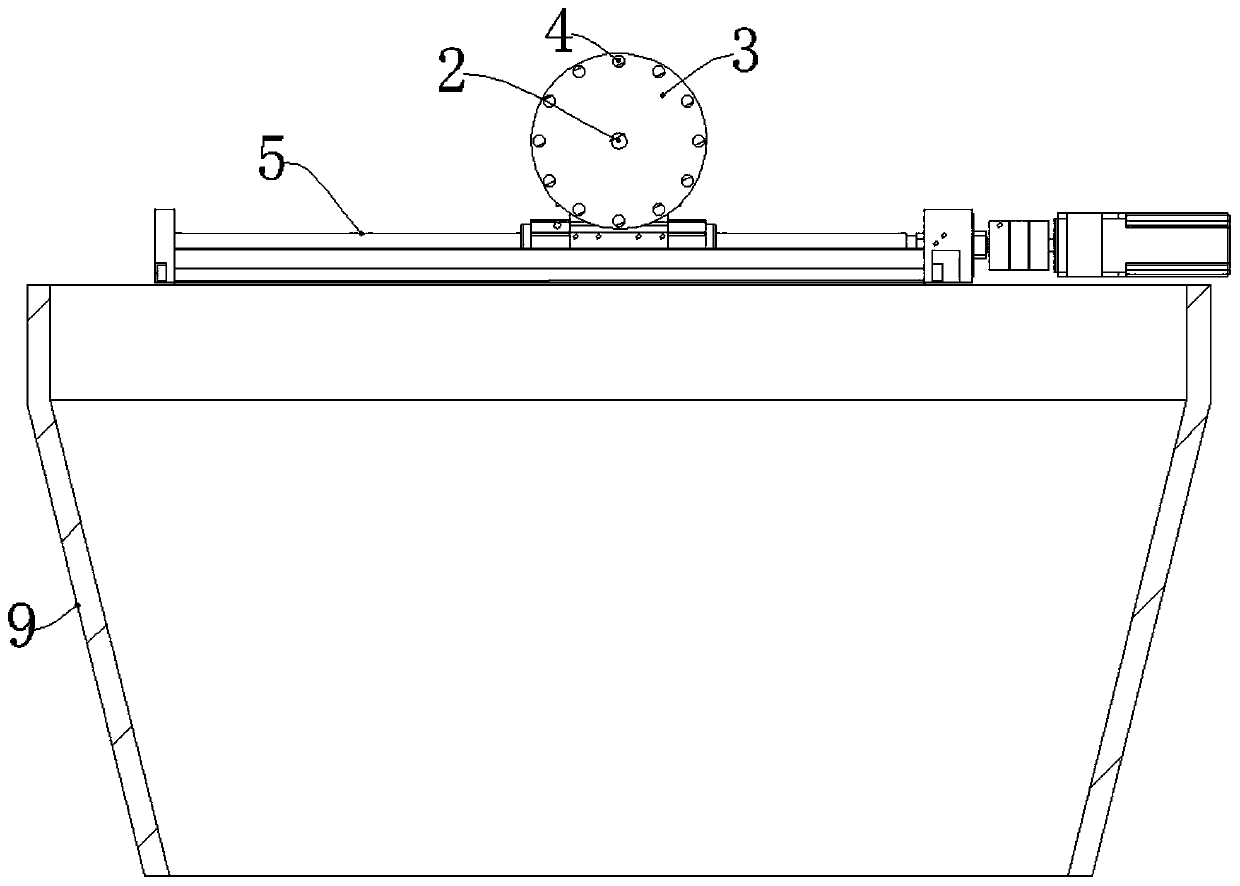

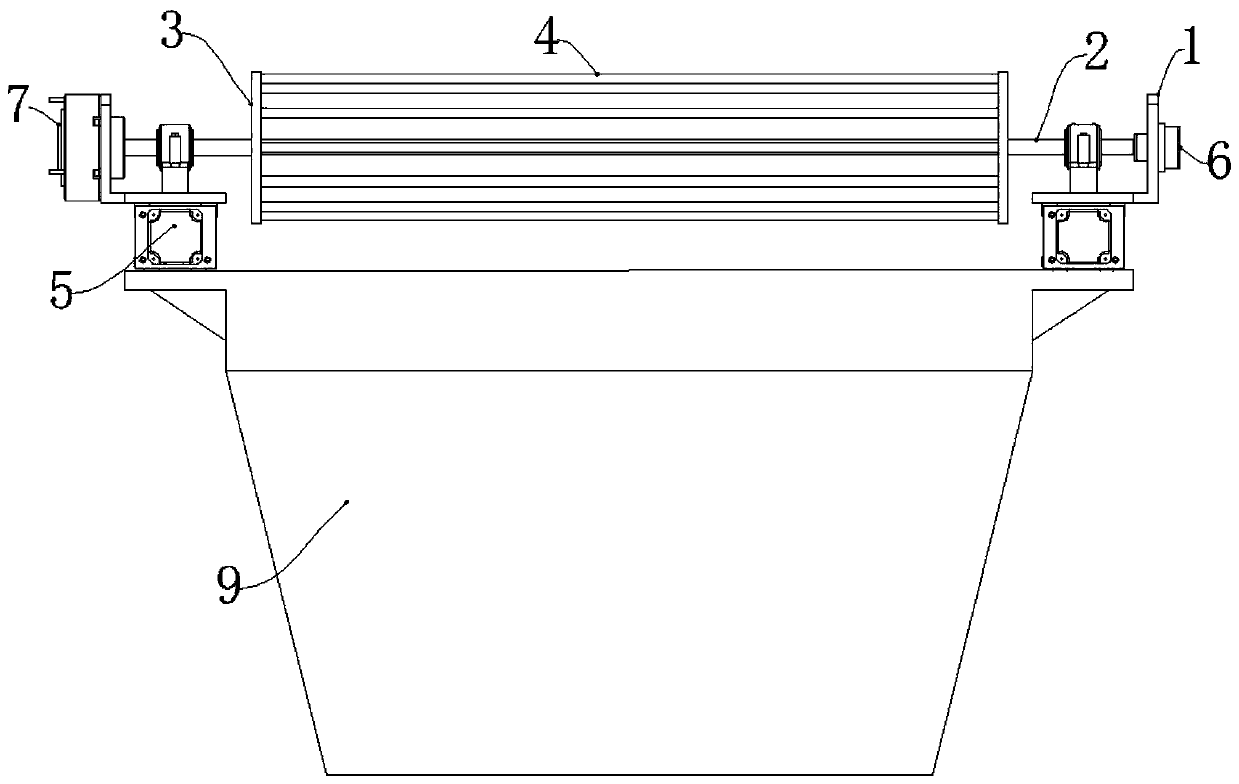

[0019] Such as Figure 1-Figure 3 As shown, a cement-stabilized gravel mixing plant anti-segregation device includes a bracket 1, an anti-segregation roller, a horizontal linear module 5, a torque sensor 6, a controller and a braking device.

[0020] Such as Figure 4 As shown, the anti-segregation device of the cement-stabilized gravel mixing plant is located at the upper port of the discharge bin 9, and the output end of the belt conveyor 8 is located above the anti-segregation device of the cement-stabilized gravel mixing plant.

[0021] The anti-segregation roller includes a rotating shaft 2, an end plate 3 and a guide rod 4, the anti-segregation roller is horizontally installed on the support 1 through the rotating shaft 2, the end plates 3 are arranged on both sides of the anti-segregation roller, and the guide The material rod 4 is fixed between the two end plates 3 , and there are multiple material guide rods 4 which are evenly spaced along the same circle with the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com