Method for optimizing real-time production advance period of reconfigurable system based on model predictive control

A technology of model predictive control and reconstruction system, applied in manufacturing computing systems, forecasting, marketing, etc., can solve the problems of neglected coordination, unrealistic, limited intermediate buffer, etc., to reduce operating costs, improve operating efficiency, and strengthen resources. Effects of coordination and predictive control capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

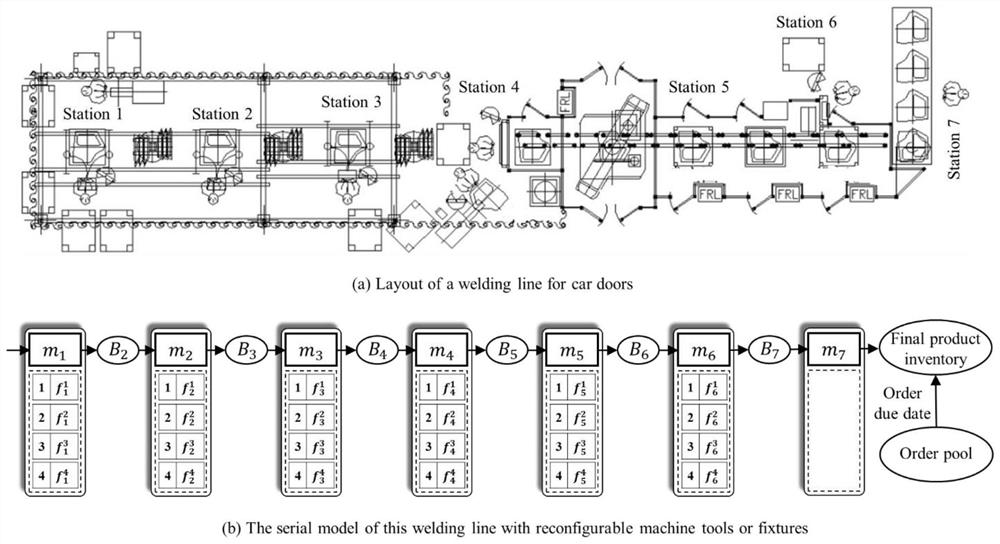

[0106] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

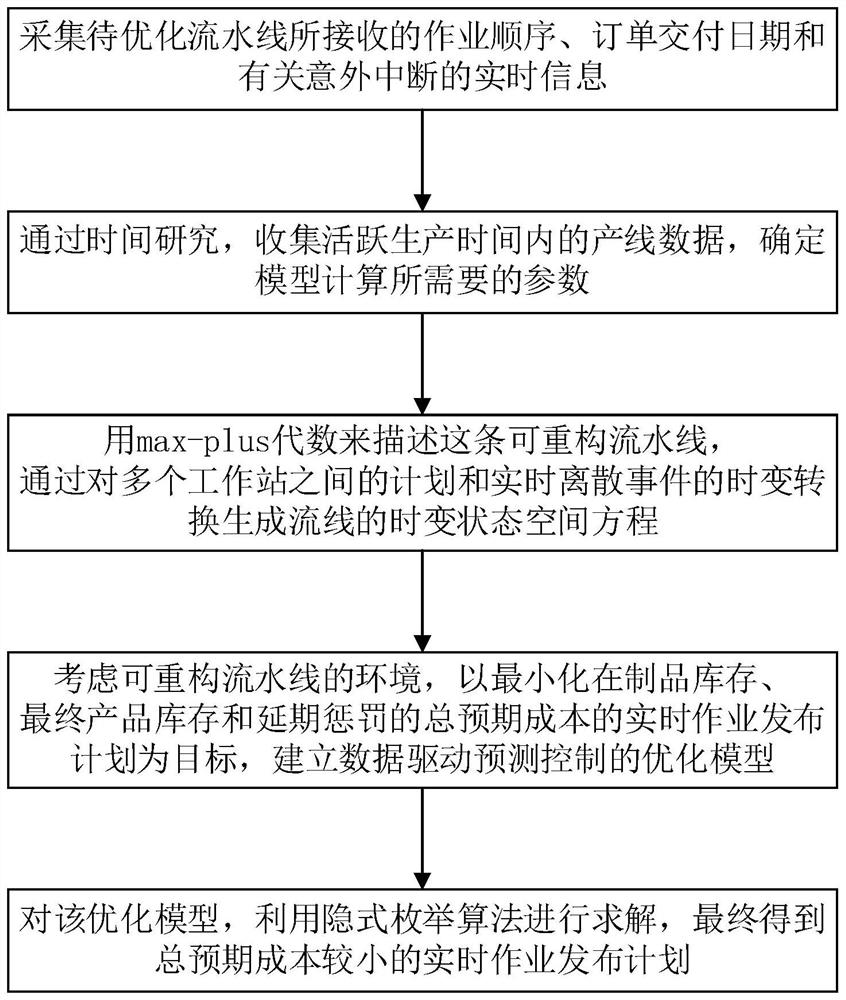

[0107] see figure 1 It is a flowchart of a real-time production lead time optimization method for a reconfigurable system based on model predictive control, which includes the following steps:

[0108] Step S1: Collect real-time data of materials and operations in the production system assembly line to be optimized and real-time data of workstation status through time research, and determine the parameters required for model calculation. Among them, the real-time data of materials and operations include at least job transfer data, job location data and processing time; real-time data on workstation status includes at least machine failure event data, job processing data, workstation reconfiguration time, and workstation buffer capacity;

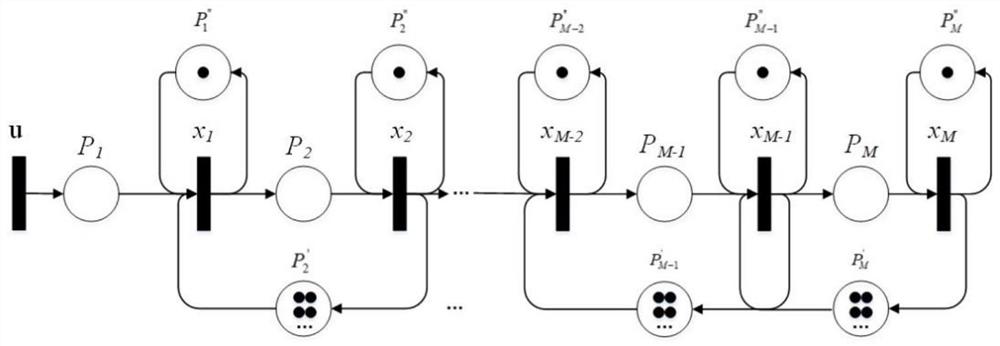

[0109] Step S2: Considering predictive multi-stage transition and reconfigurable behavior...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com