Friction transmission belt

A technology of friction transmission belt and friction transmission, which is applied in transmission belts, V-belts, belts/chains/gears, etc., which can solve problems such as stick-slip noise, achieve the effect of improving durability and maintaining transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~17 and comparative example 1~8

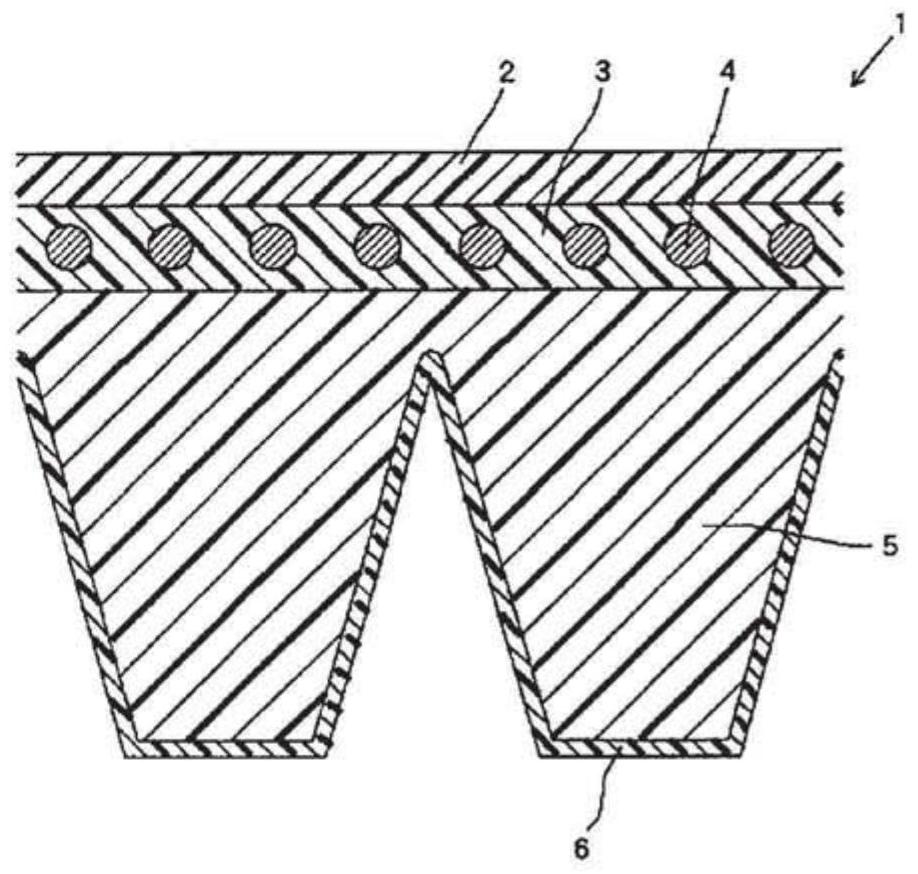

[0182] [Surface layer and compression rubber layer]

[0183] For the surface layer and compression rubber layer forming the drive surface (contact surface with the pulley) of the belt, the rubber composition for the surface layer and compression rubber layer of the formulation shown in Table 1 was kneaded at 140° C. using a Banbury mixer. , was rolled to a predetermined thickness with a calender roll, and the resulting sheet was used. The thickness of the sheet for the surface layer was adjusted so that the thickness of the surface layer was 500 μm. In addition, in Comparative Examples 1 and 5, no surface layer was formed, and in Comparative Example 8, a surface layer described later was formed.

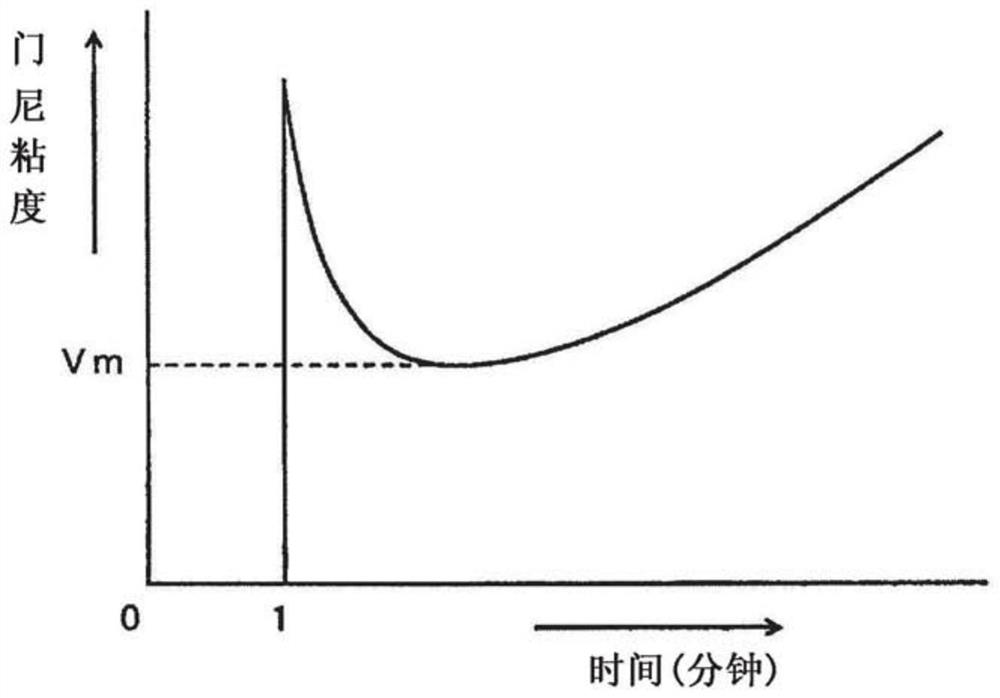

[0184] [Physical properties of cross-linked rubber of composition for surface layer and compression rubber layer]

[0185] The uncrosslinked (unvulcanized) rubber sheet for the surface layer and the compression rubber layer was pressurized and heated (temperature 180° C., surface p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com