Cleaning method of scrubber

A washing machine and cleaning technology, applied in the directions of cleaning machinery, cleaning equipment, manual floor scrubbing machinery, etc., can solve the problems such as the decline of the cleaning effect of the washing machine, the unsustainable and effective water spray, the weakening of the water pump pressure and the water volume, etc. Achieve the effect of shortening the waiting time, stabilizing the water output and water pressure, and preventing the water spray from being too large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

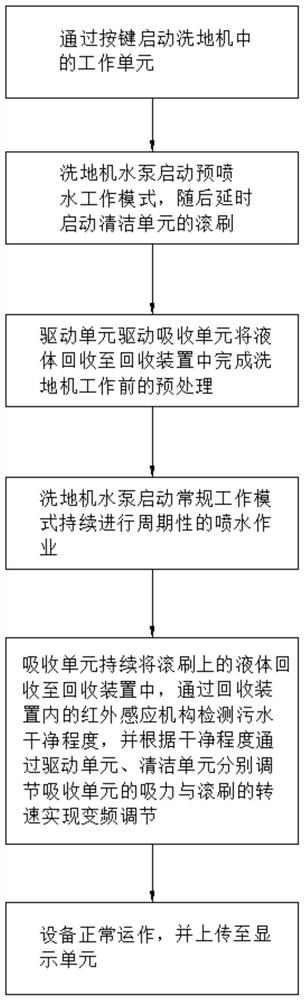

[0048] see figure 1 , the present invention provides a technical solution: a cleaning method for a floor washing machine, comprising the following steps:

[0049] Step 1: Start the working unit in the scrubber by pressing the button. The working unit includes a power supply unit, a display unit, a drive unit (main motor), an absorption unit (vacuum suction), a cleaning unit (floor brush assembly), a receiving unit, and a water shortage unit. The detection unit and the rolling brush stall detection unit, the power supply unit starts, and sends a start-up command; the display unit receives the start-up command; the drive unit (main motor) starts power-on operation, and the absorption unit (vacuum suction) continues to run; the cleaning unit (floor brush assembly) Power-on operation; the water shortage detection unit is turned on; the rolling brush stall detection unit is turned on;

[0050] Step 2: The water pump of the floor washing machine starts the pre-spray water working m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com