Controlling IMAP of engine to facilitate regeneration process

A technology for control process, regeneration process, applied in the direction of engine components, combustion engines, engine control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

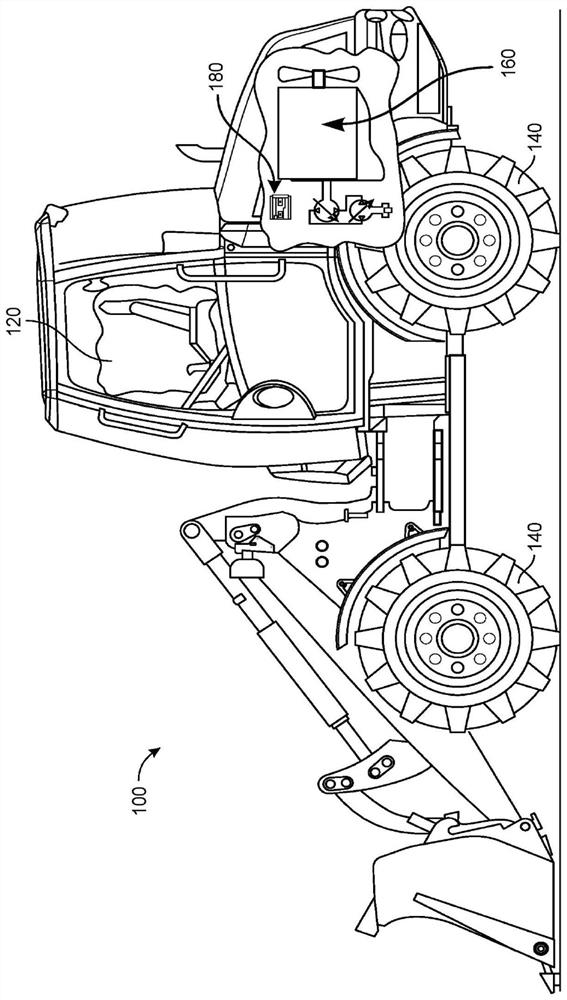

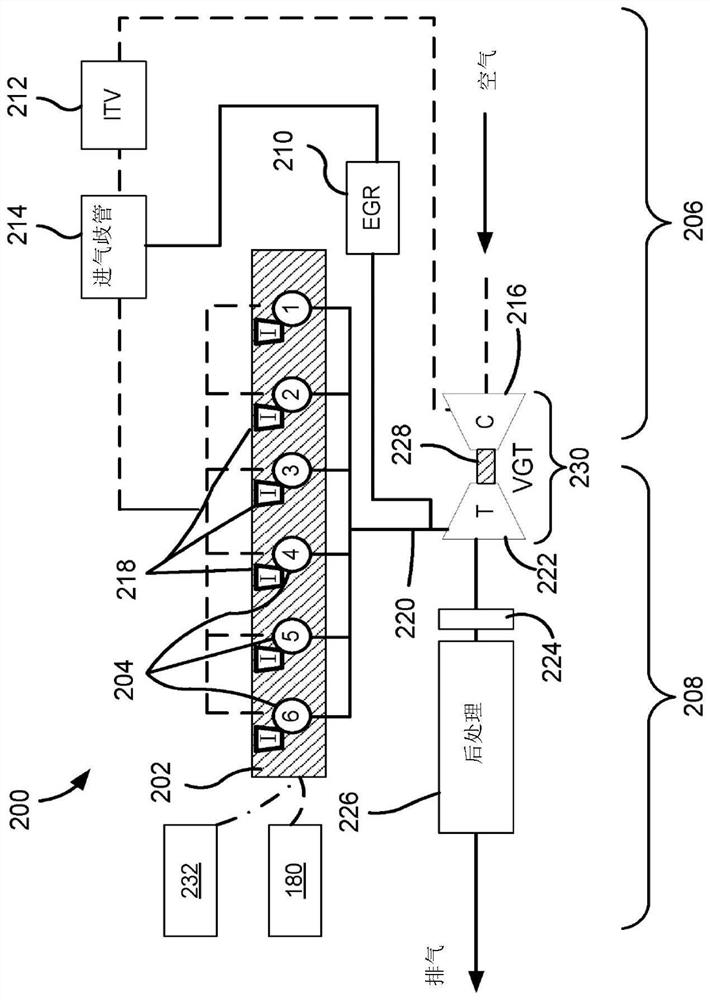

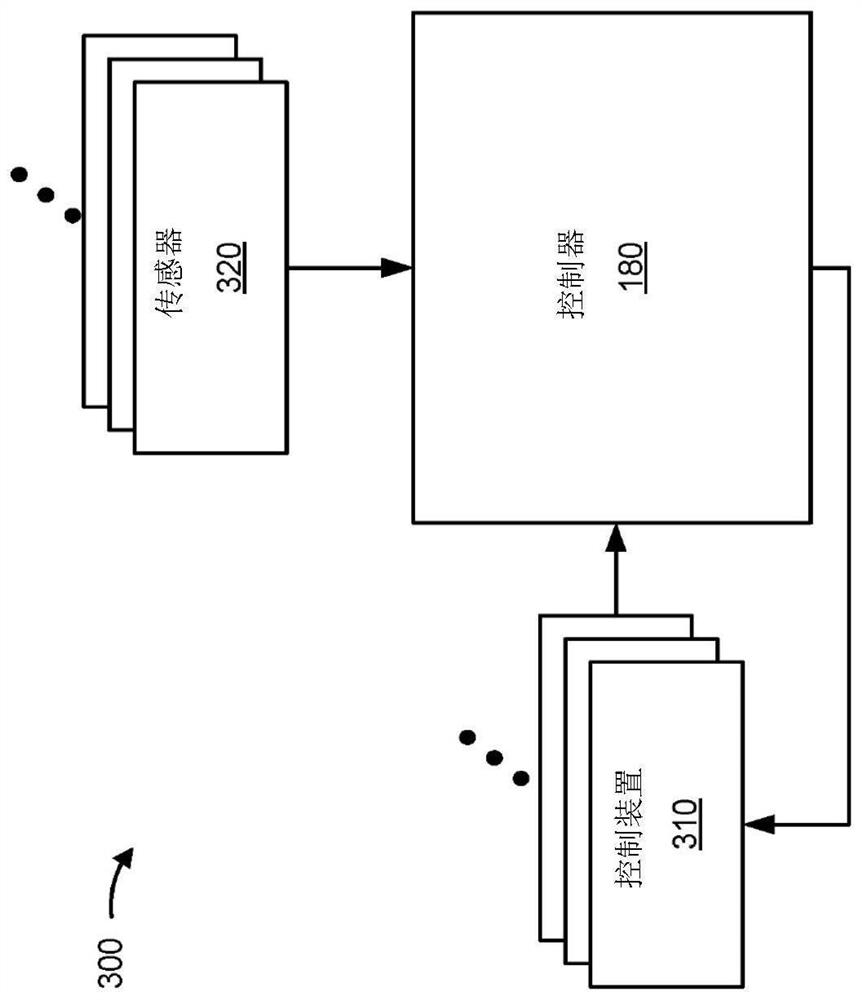

[0013] The present disclosure relates to a controller, such as an engine control module (ECM), that controls the engine's VGT and / or ITV to control the engine's IMAP and thereby exhaust (eg, exhaust gas produced by the engine) temperature to facilitate regeneration process. As described herein, a controller, VGT and / or ITV is of general applicability to any machine utilizing such a controller, VGT and / or throttle. The term "machine" may refer to any machine that performs operations associated with an industry such as, for example, mining, construction, agriculture, transportation, or any other industry. As some examples, the machine may be a vehicle, off-road truck, backhoe loader, cold planer, wheel loader, compactor, feller buncher, forestry machine, forwarder, harvester, excavator, industrial loader, Steering arm loaders, material handlers, graders, pipelayers, road reclaimers, skid steers, skidders, telehandlers, tractors, bulldozers, tractor scrapers or other surface equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com