Method for forming IGBT electric field stop layer

A technology of electric field termination layer and substrate, which is applied in circuits, electrical components, semiconductor devices, etc., and can solve problems affecting IGBT reliability, IGBT turn-off oscillation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] like Figure 1-13 As shown, an embodiment of the present invention provides a method for forming an electric field stop layer of an IGBT, and the method includes the following steps:

[0042] S1. Substrate preparation, the substrate is a uniformly doped N-type silicon-based substrate (see figure 1 );

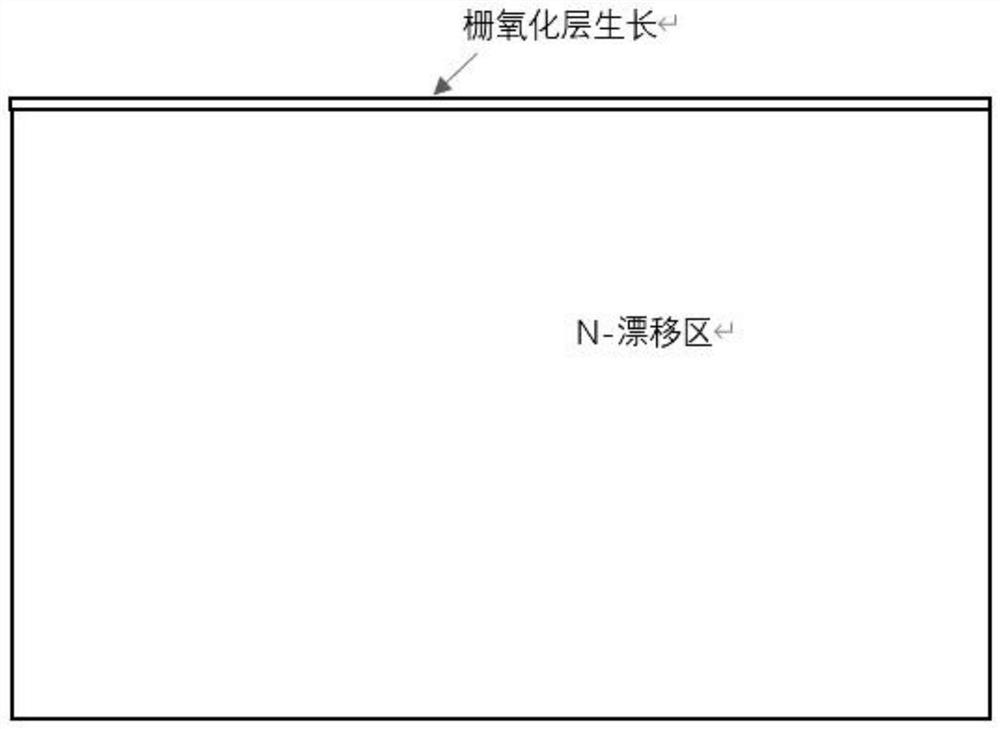

[0043] S2, the growth of gate oxide layer, the condition is 1100-1150 ℃ dry oxygen growth method (see figure 2 );

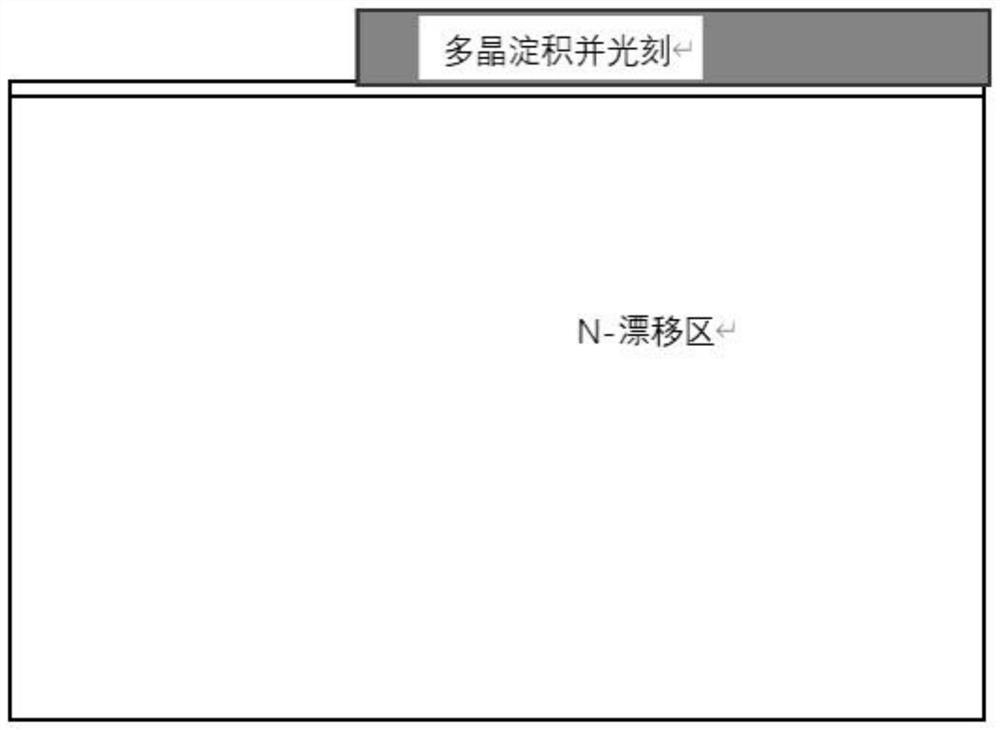

[0044] S3, polycrystalline deposition and photolithography, the thickness of the deposited polycrystalline is about 1um, and the sheet resistance after doping is 4-16ohm / sq (see image 3 );

[0045] S4, P-type body region implantation, for B impurity implantation, the implantation dose is 2-10e13 / cm 2 , the injection energy is 60-100Kev (see Figure 4 );

[0046] S5, P-type body area push, push temperature is 1150 ℃, time is 90-120min (see Figure 5 );

[0047] S6, N+ is injected and pushed, and As is injected, the dose is 5e15 / cm 2 -10e15 / cm 2 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com