Patents

Literature

51 results about "High energy proton" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

See the answer. In proton-beam therapy, a high-energy beam of protons is fired at a tumor. The protons come to rest in the tumor, depositing their kinetic energy and breaking apart the tumor’s DNA, thus killing its cells.

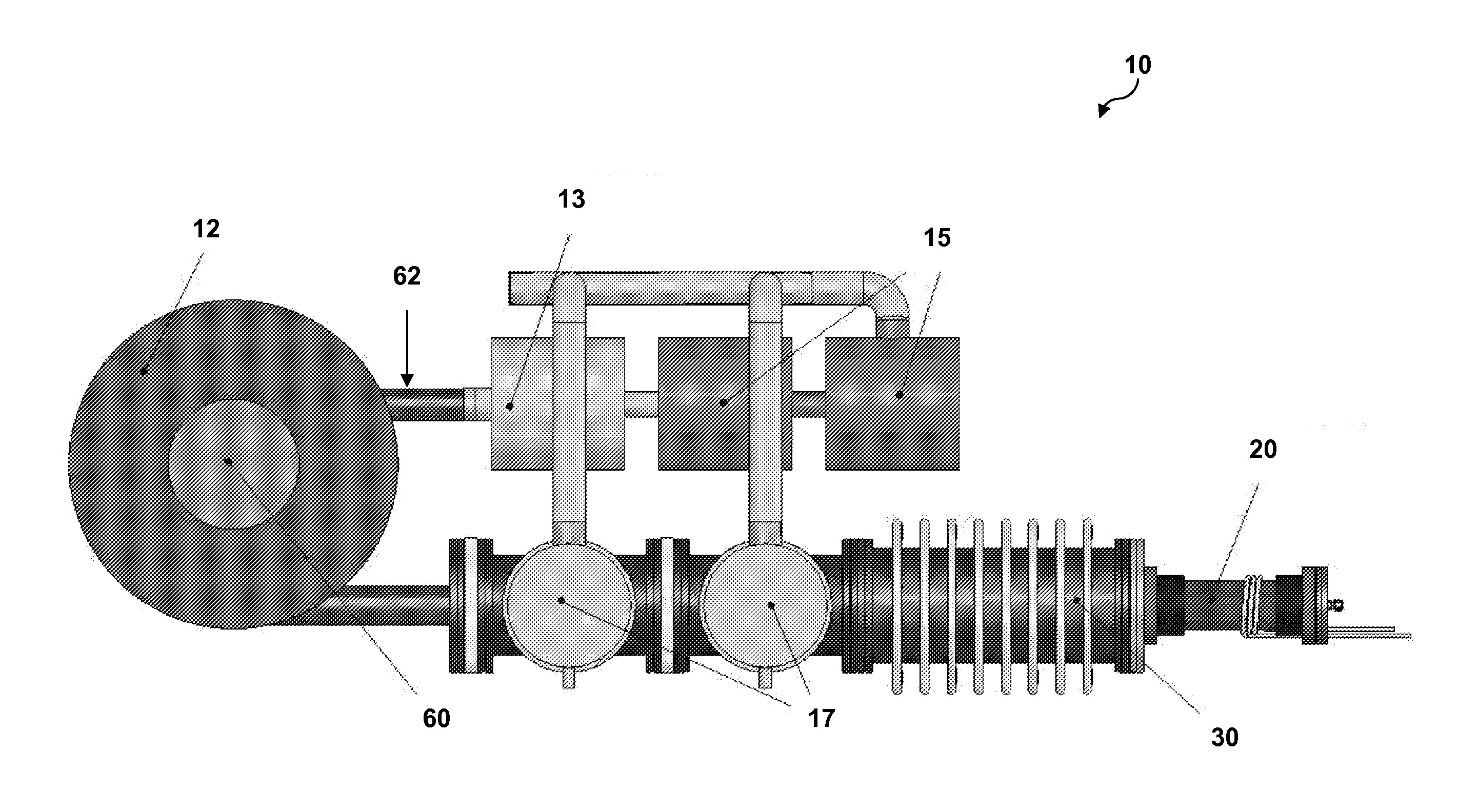

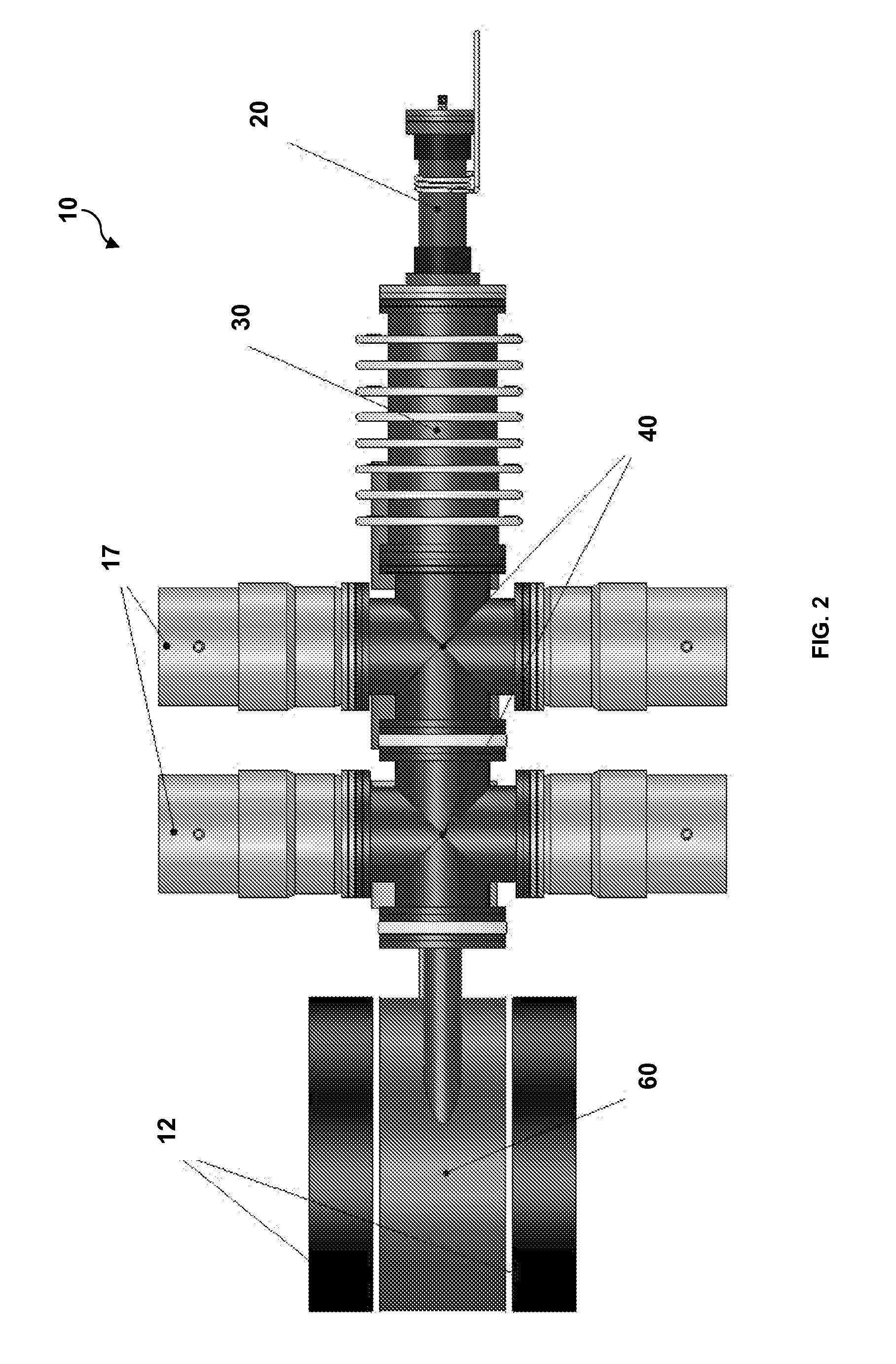

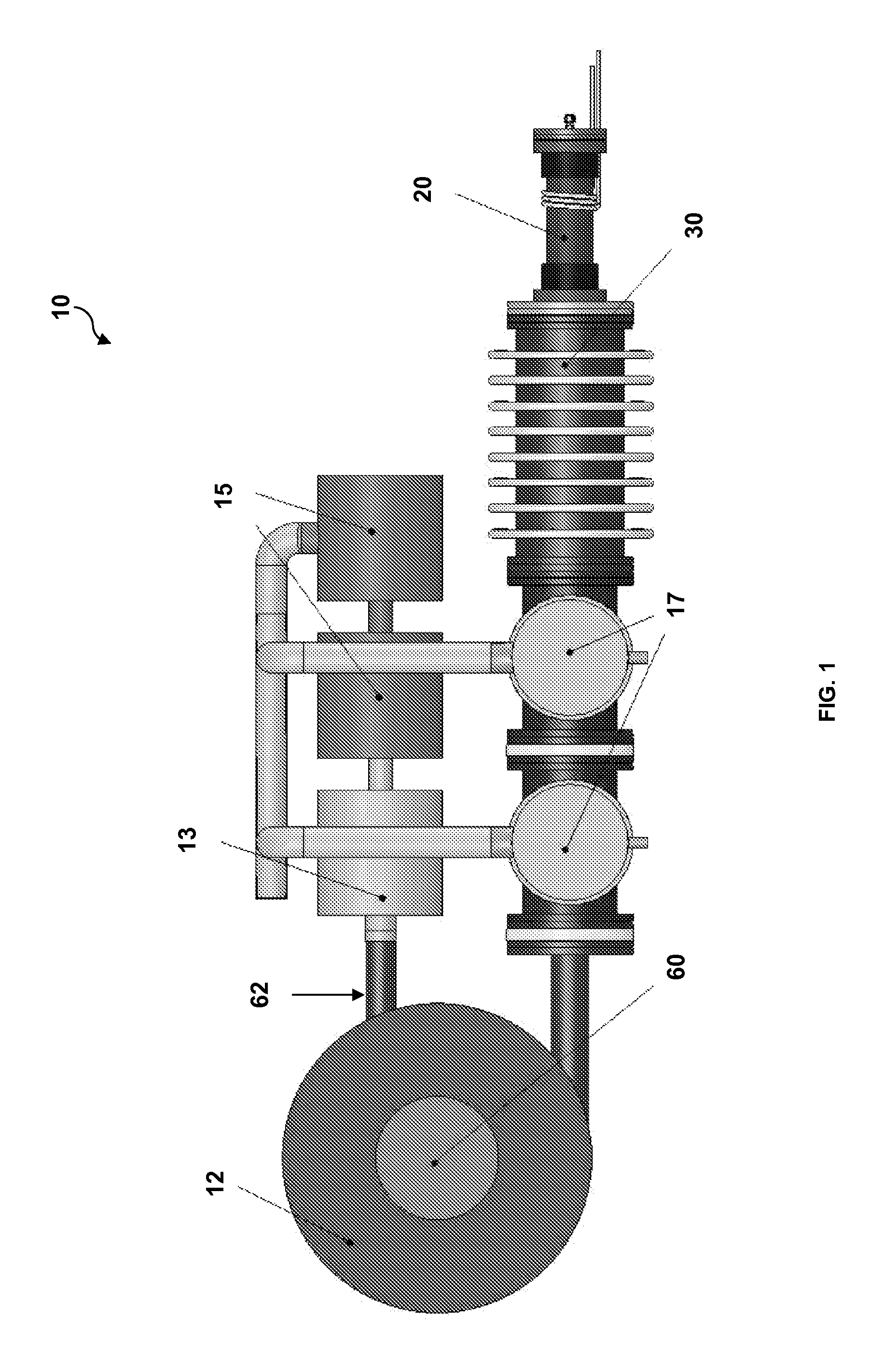

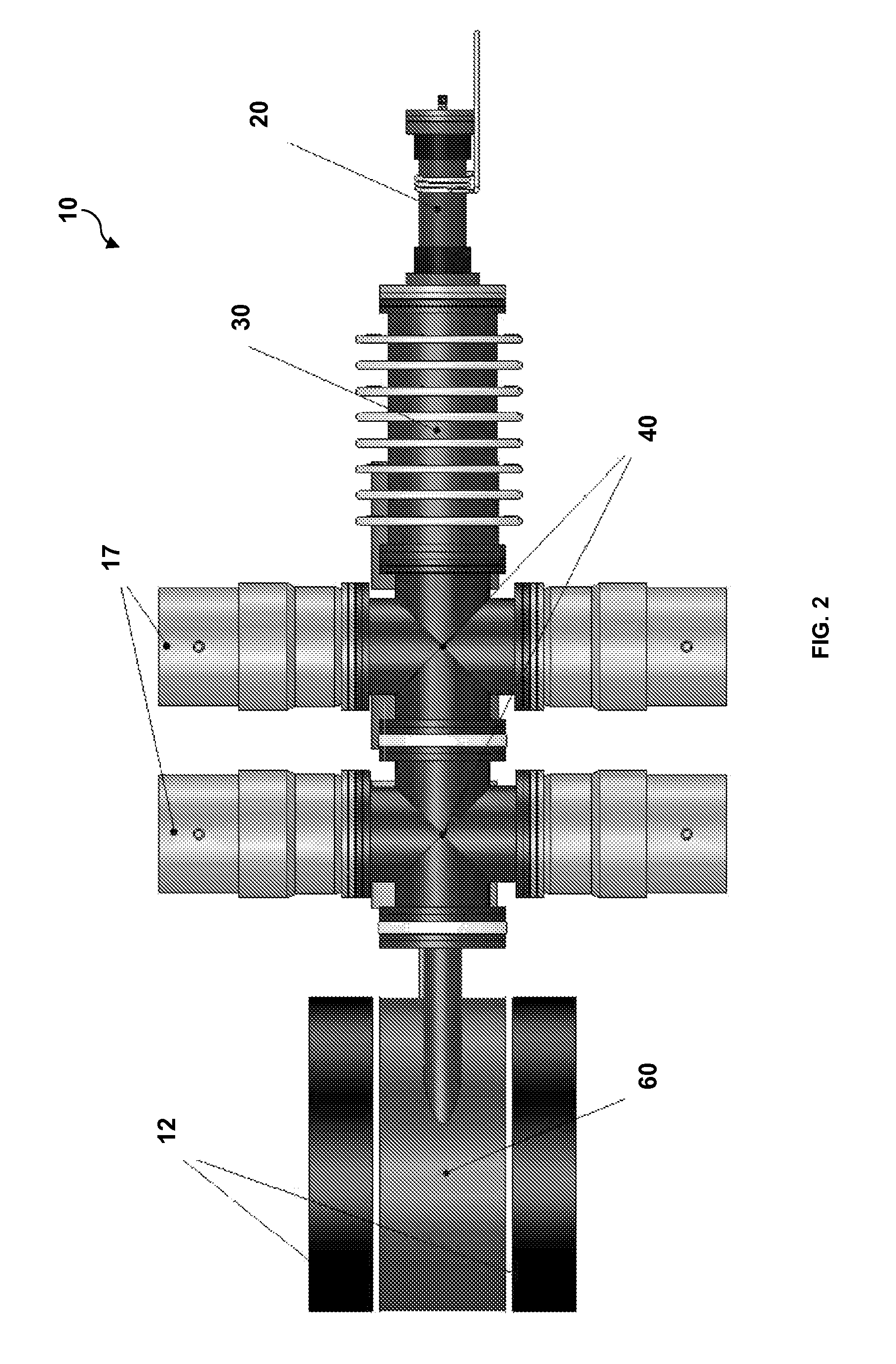

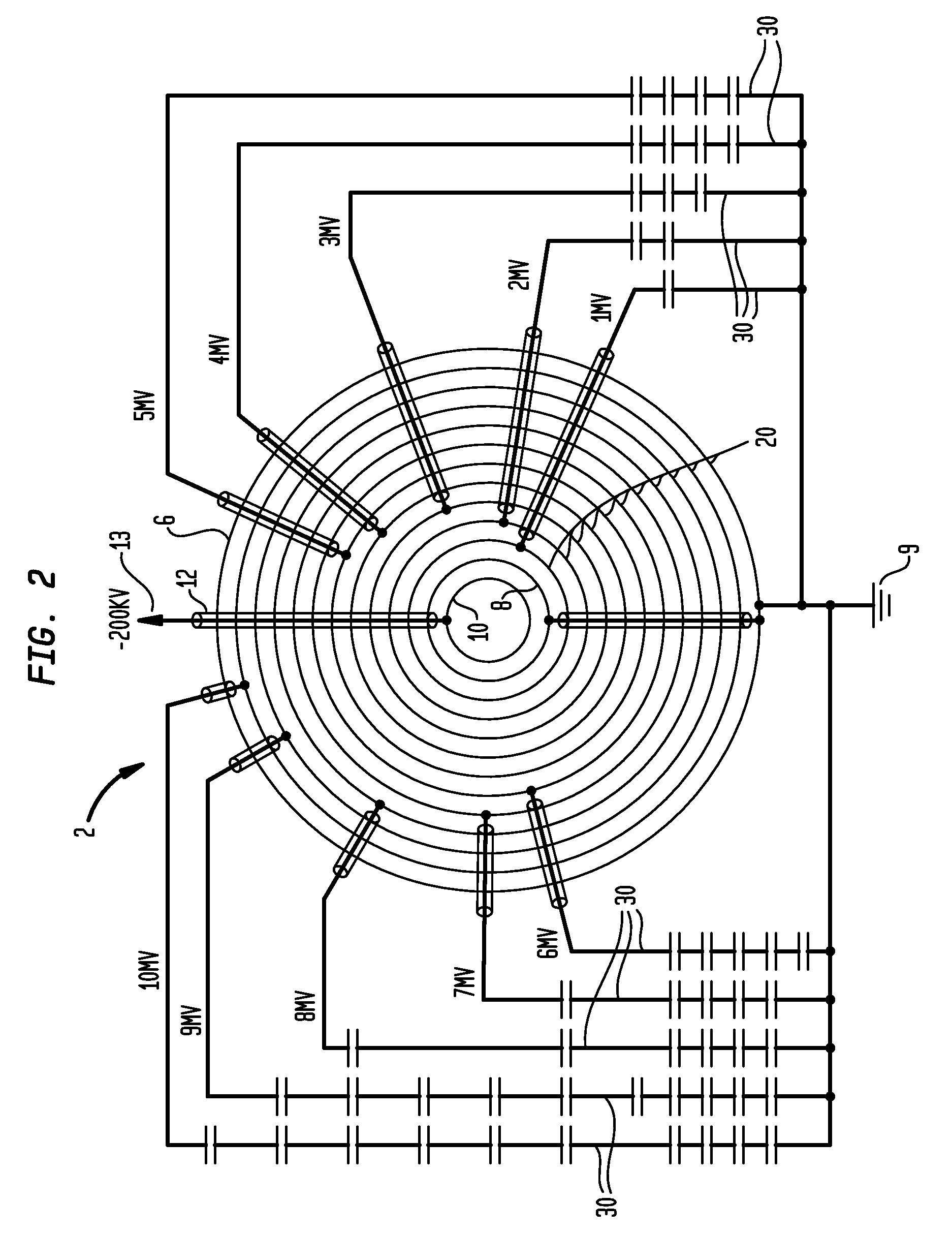

RF accelerator method and apparatus used in conjunction with a charged particle cancer therapy system

ActiveUS20100060209A1Stability-of-path spectrometersBeam/ray focussing/reflecting arrangementsLow voltageCharged particle radiotherapy

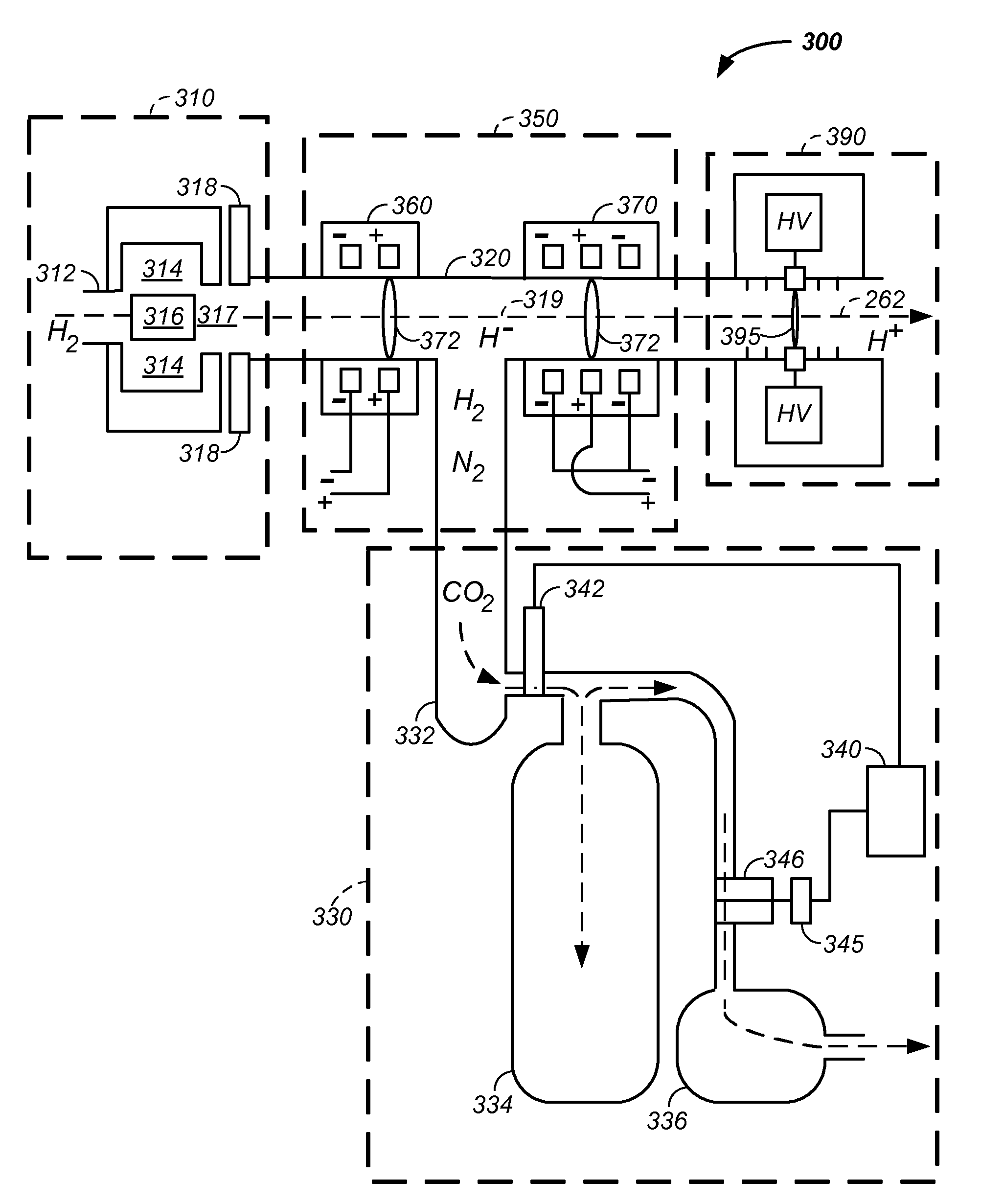

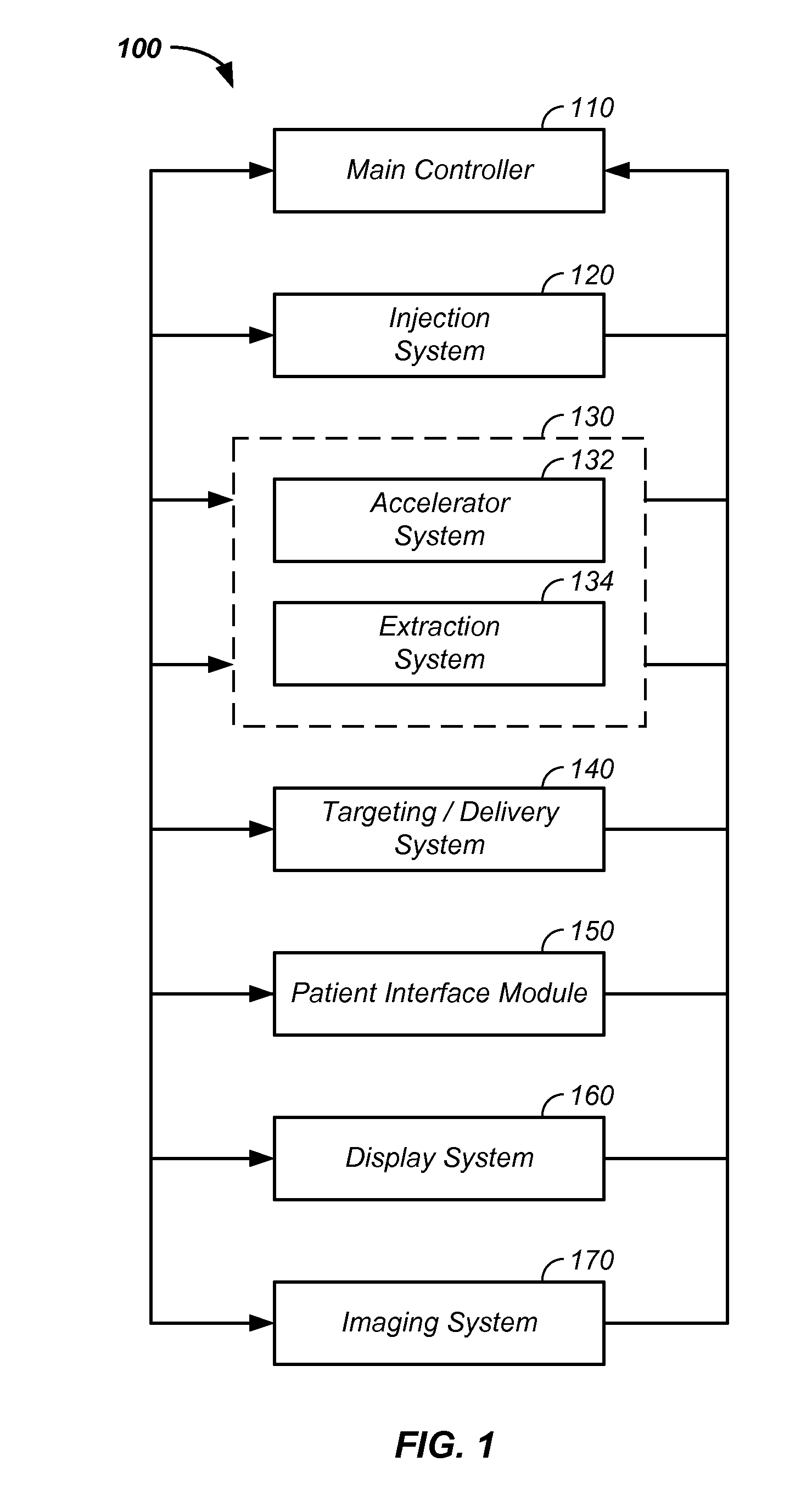

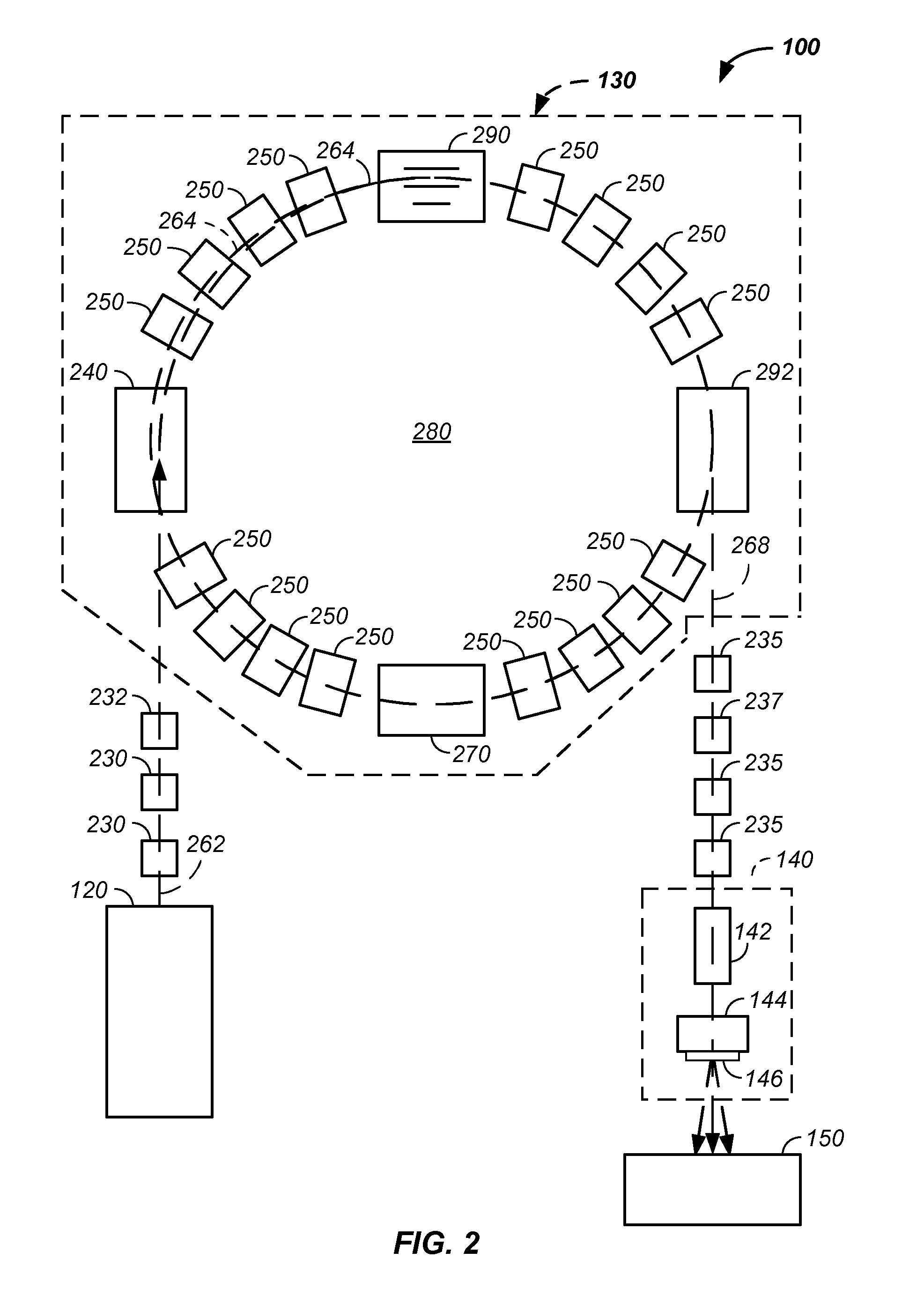

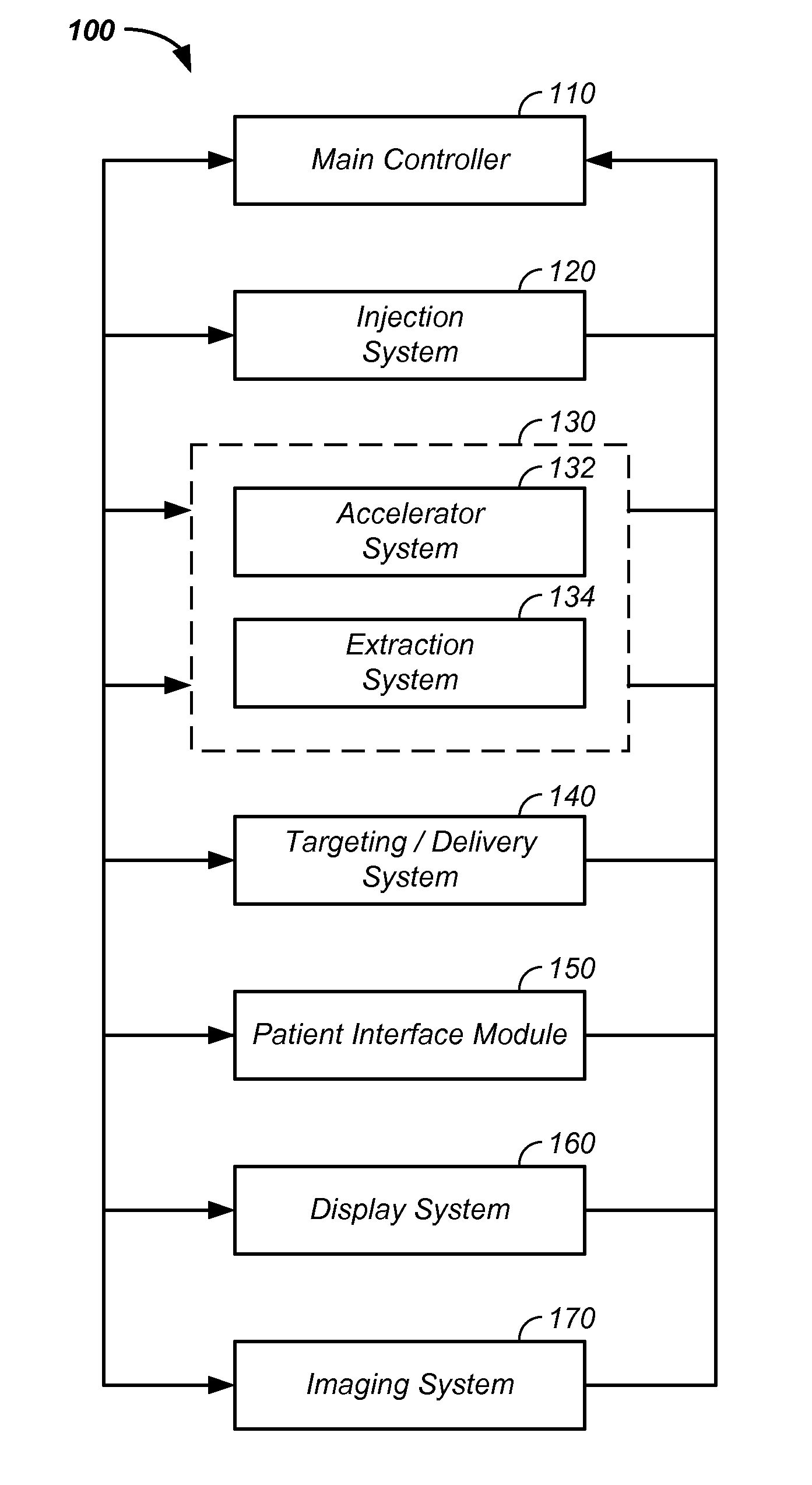

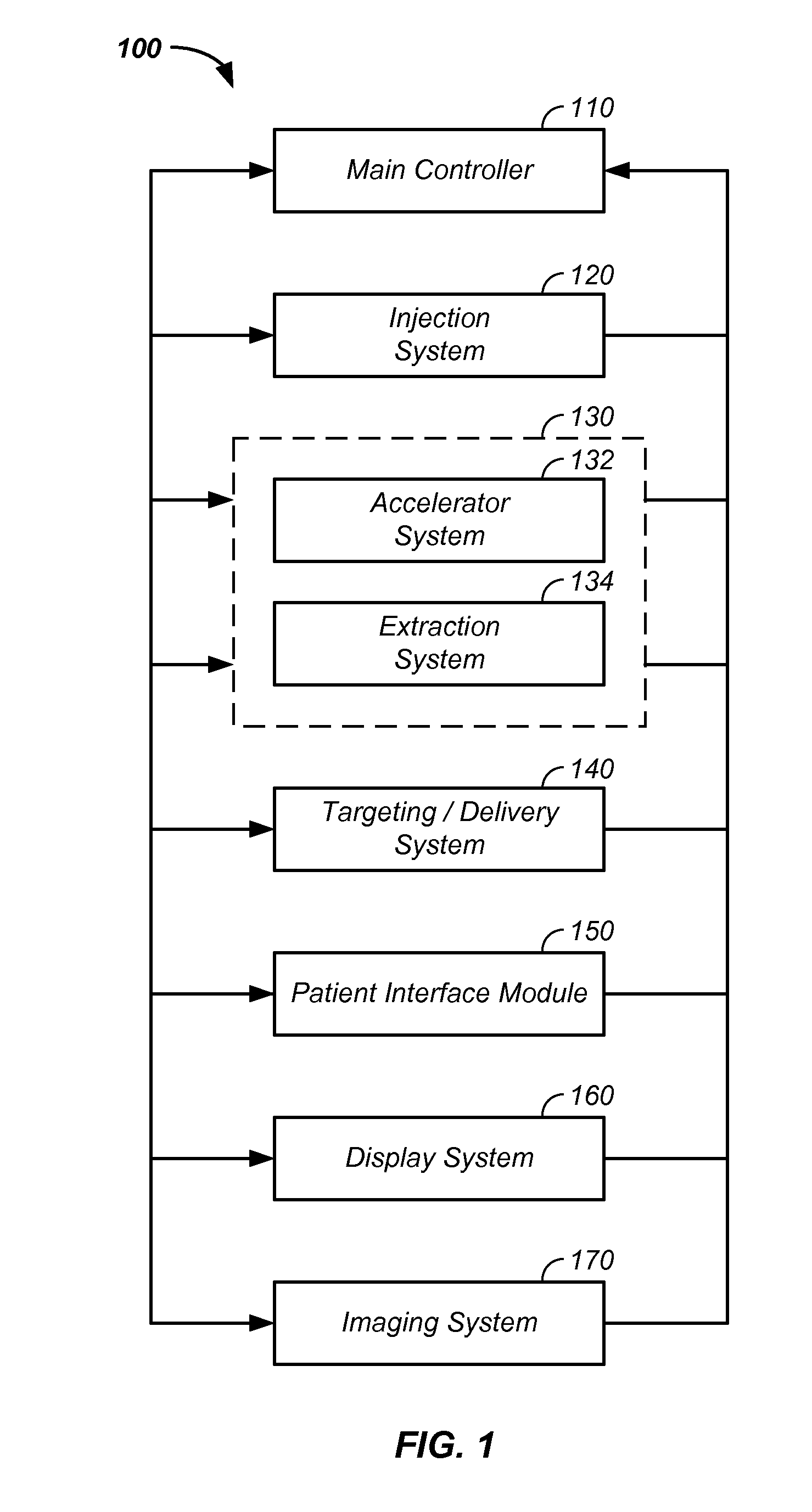

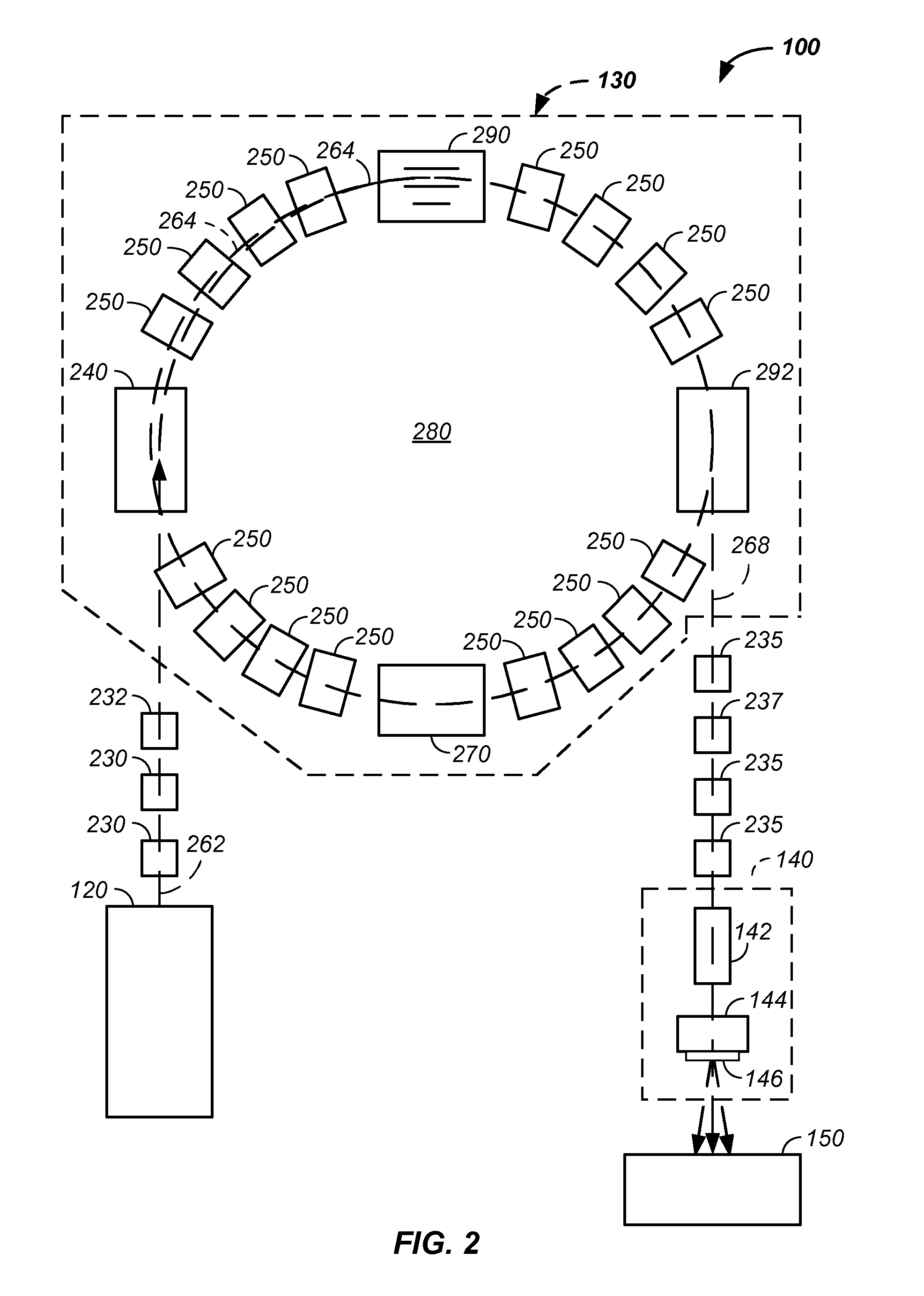

The invention comprises a radio-frequency accelerator method and apparatus used in conjunction with multi-axis charged particle radiation therapy of cancerous tumors. An RF synthesizer provides a low voltage RF signal, that is synchronized to the period of circulation of protons in the proton beam path, to a set of integrated microcircuits, loops, and coils where the coils circumferentially enclose the proton beam path in a synchrotron. The integrated components combine to provide an accelerating voltage to the protons in the proton beam path in a size compressed and price reduced format. The integrated RF-amplifier microcircuit / accelerating coil system is operable from about 1 MHz, for a low energy proton beam, to about 15 MHz, for a high energy proton beam.

Owner:BALAKIN ANDREY VLADIMIROVICH +1

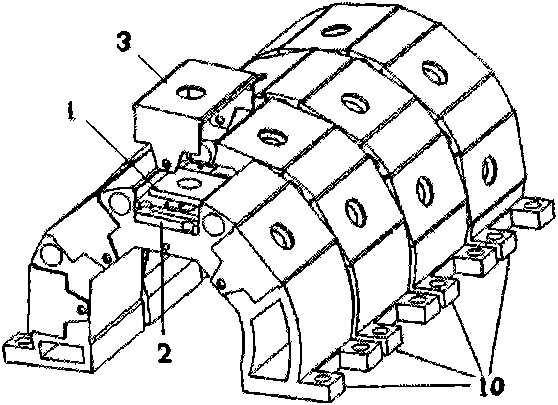

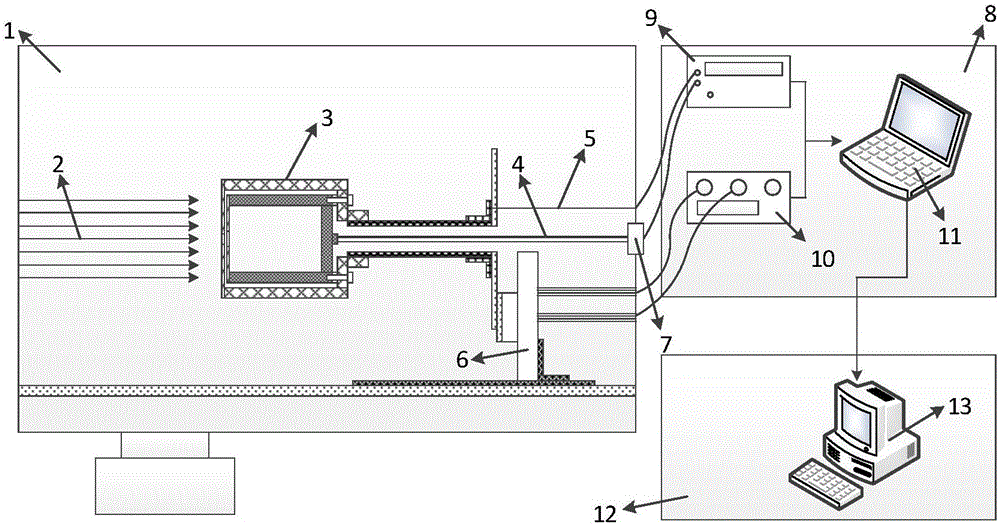

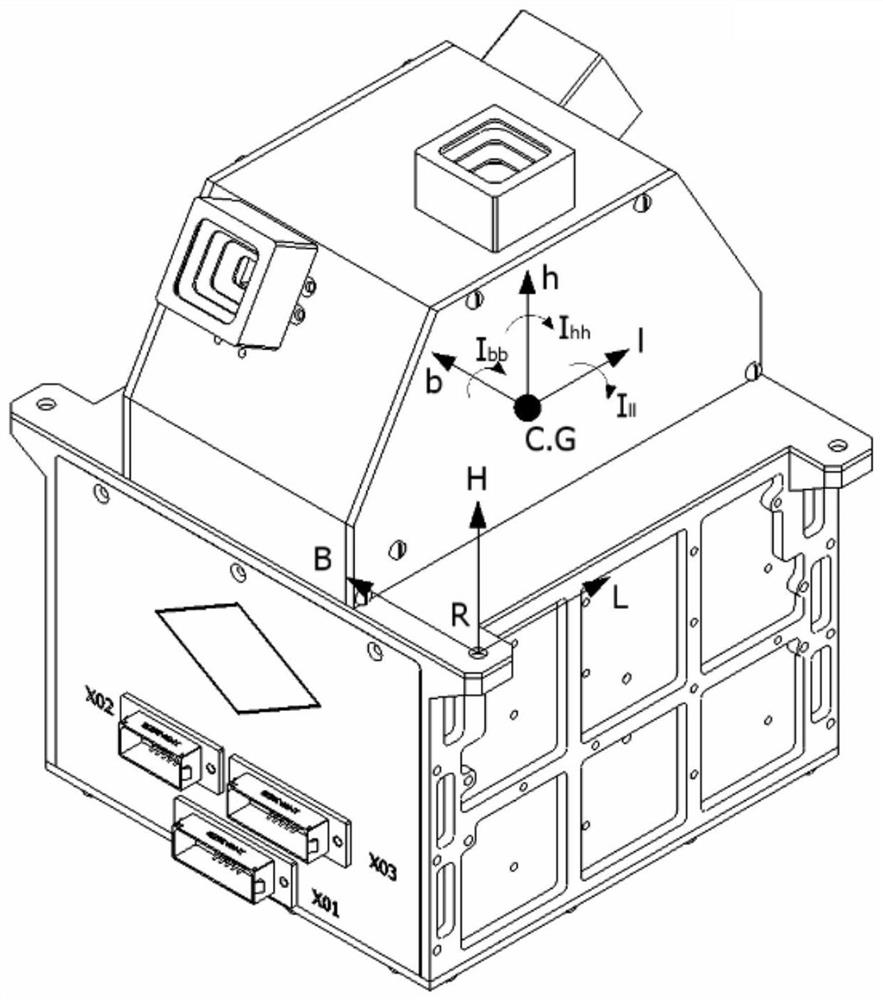

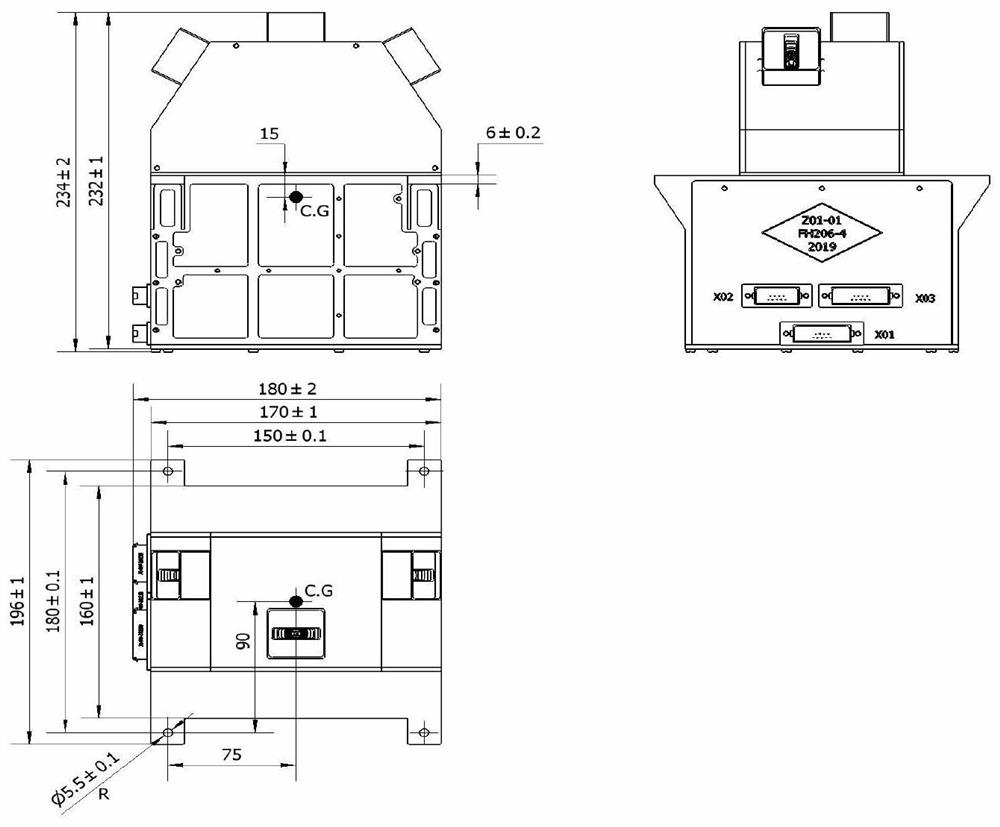

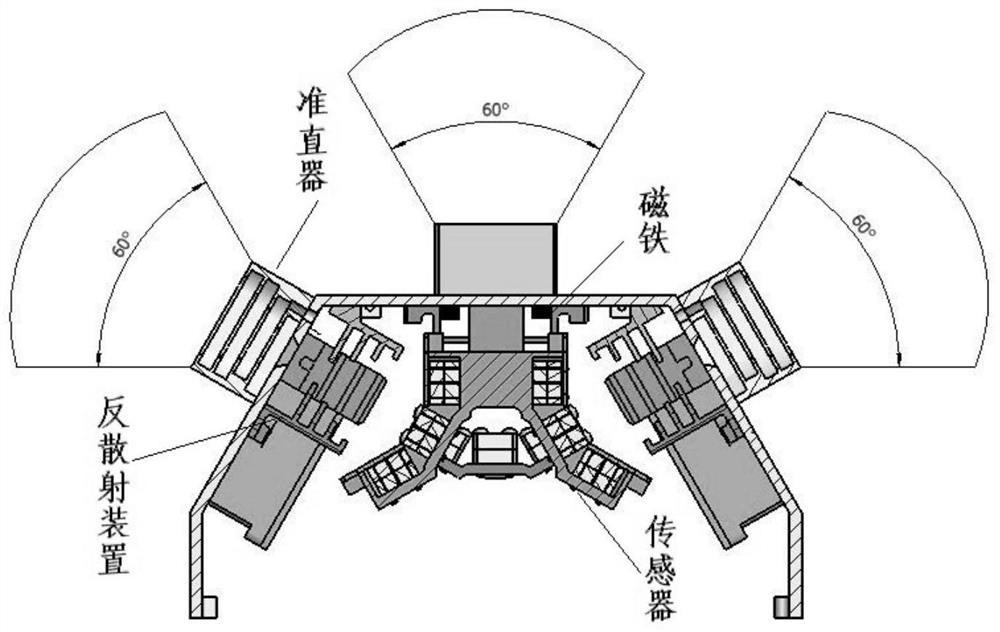

Multidirectional high energy particle detector

InactiveCN102183779AAchieve integrationAchieve directional fluxX-ray spectral distribution measurementRadiation intensity measurementAudio power amplifierHigh energy

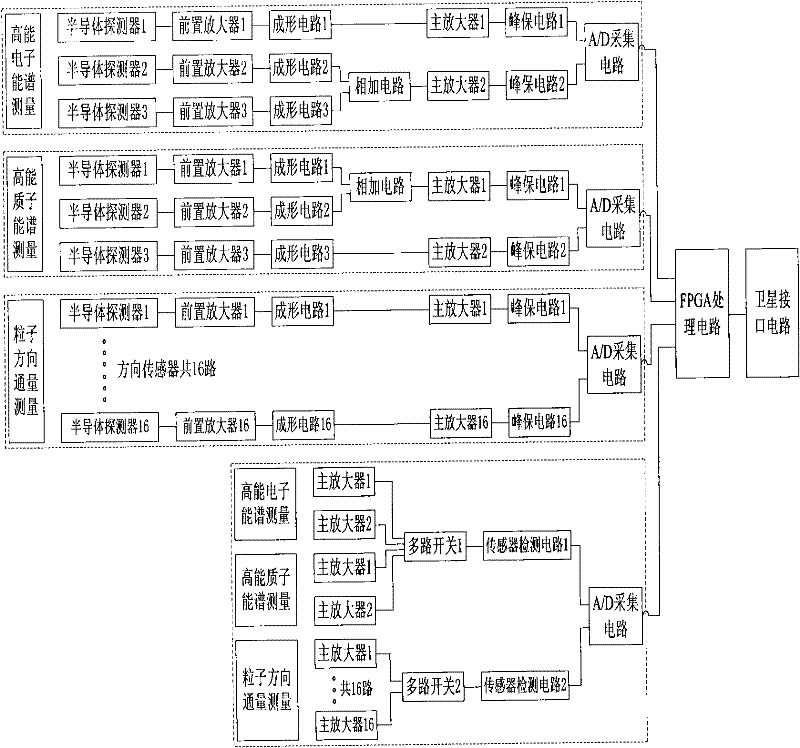

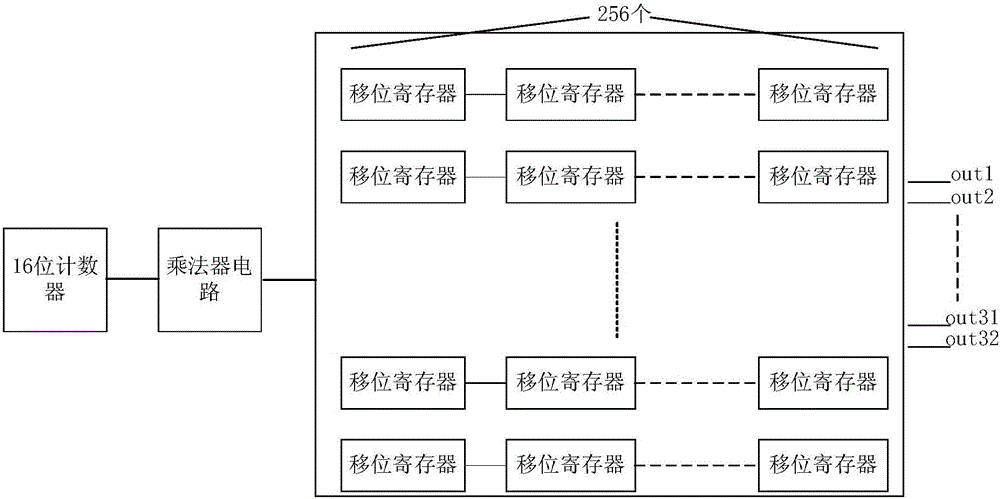

The invention relates to a multidirectional high energy particle detector. The detector includes a direction sensor which includes semiconductor detectors, the semiconductor detectors are staggeredly arranged in four rows on a side cylinder of a cylindrical pedestal which has a semi-circular cross section, and the semiconductor detectors are positioned with an interval angle of 11.25 degrees; a high energy electron spectrum sensor which includes three different conductor detectors; a high energy particle spectrum sensor which includes three different semiconductor detectors; main amplifiers; peak value retainers; ADC collection circuits; an FPGA processing chip; wherein the output terminals of preposing amplifiers are connected with the corresponding output terminals of the main amplifiers respectively via forming circuits, the output terminals of main discharge circuits are connected with the corresponding output terminals of the peak value retainers respectively, the output terminals of the peak value retainers are connected with the corresponding output terminals of the ADC collection circuits respectively, and the output terminals of the ADC collection circuits are connected with the output terminal of the FPGA processing chip after the analog-digital conversion. The detector detects the flux of the high energy particle along a 180 degrees sector direction, and also detects the power spectrum of the high energy particle along a vertical sector direction.

Owner:NAT SPACE SCI CENT CAS

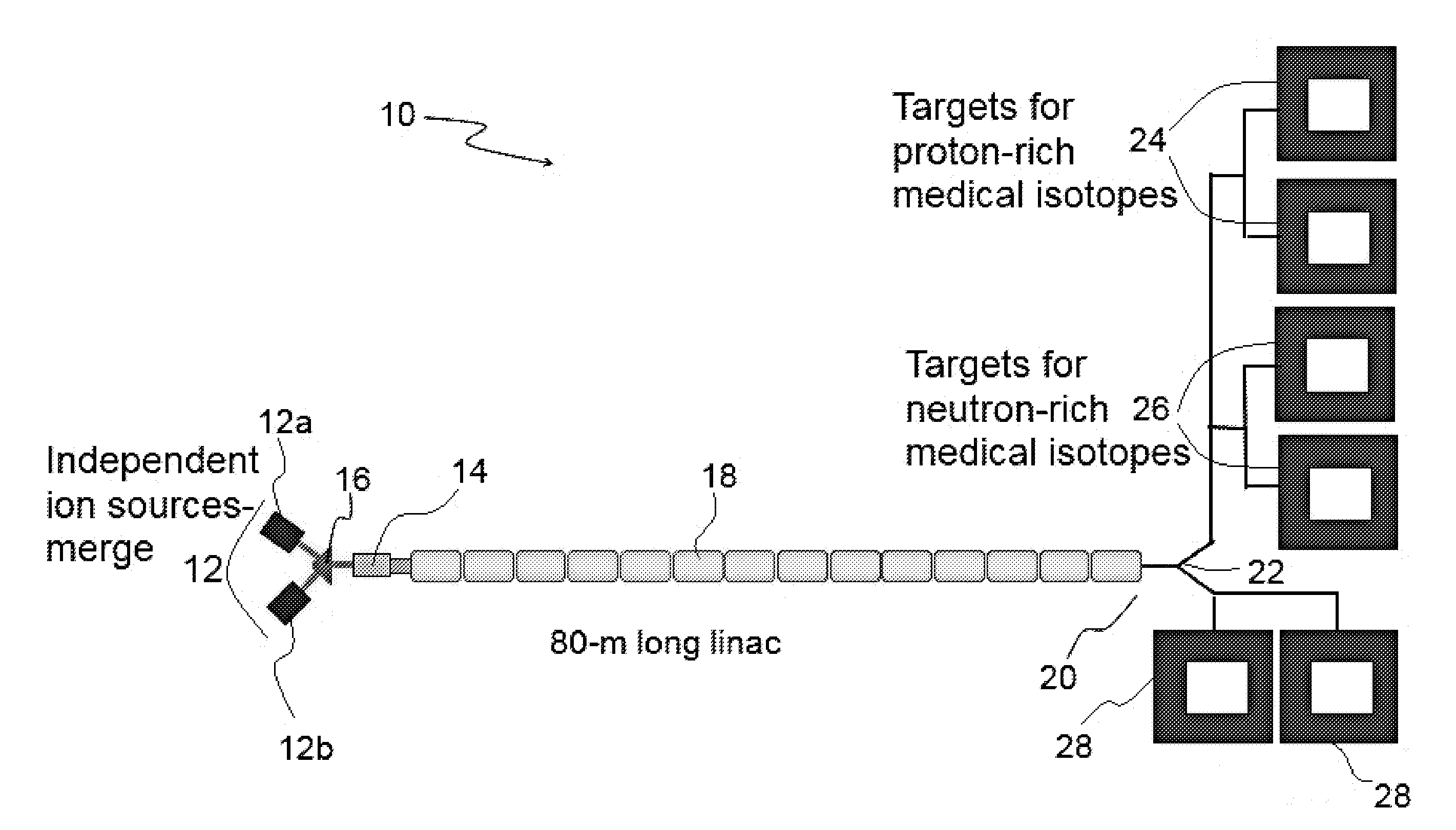

High energy proton or neutron source

ActiveUS20100284502A1Overcome disadvantagesPrevent escapeConversion outside reactor/acceleratorsNuclear targetsHigh fluxIsotope

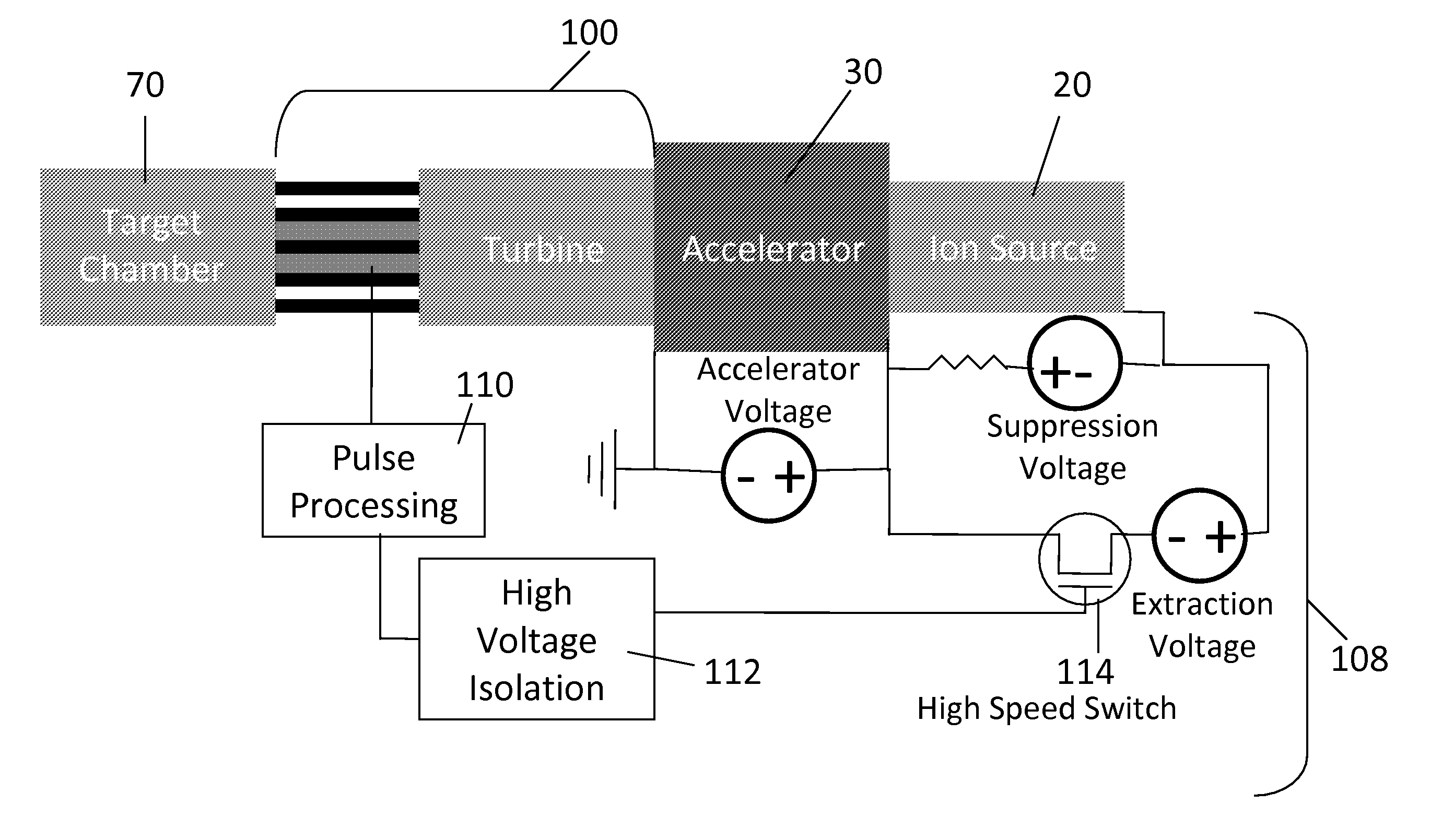

The invention provides a compact high energy proton source useful for medical isotope production and for other applications including transmutation of nuclear waste. The invention further provides a device that can be used to generate high fluxes of isotropic neutrons by changing fuel types. The invention further provides an apparatus for the generation of isotopes including but not limited to 18F, 11C, 15O, 63Zn, 124I, 133Xe, 111In, 125I, 131I, 99Mo, and 13N.

Owner:SHINE TECH LLC

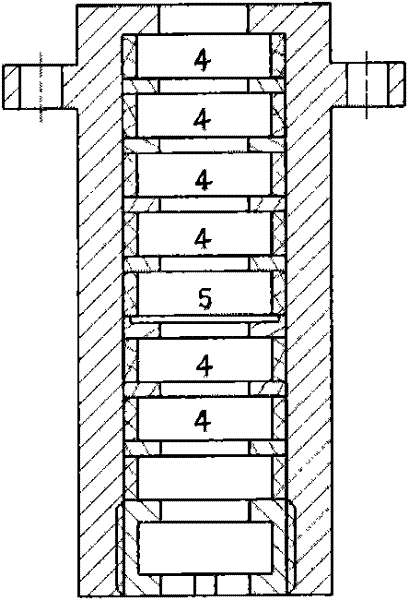

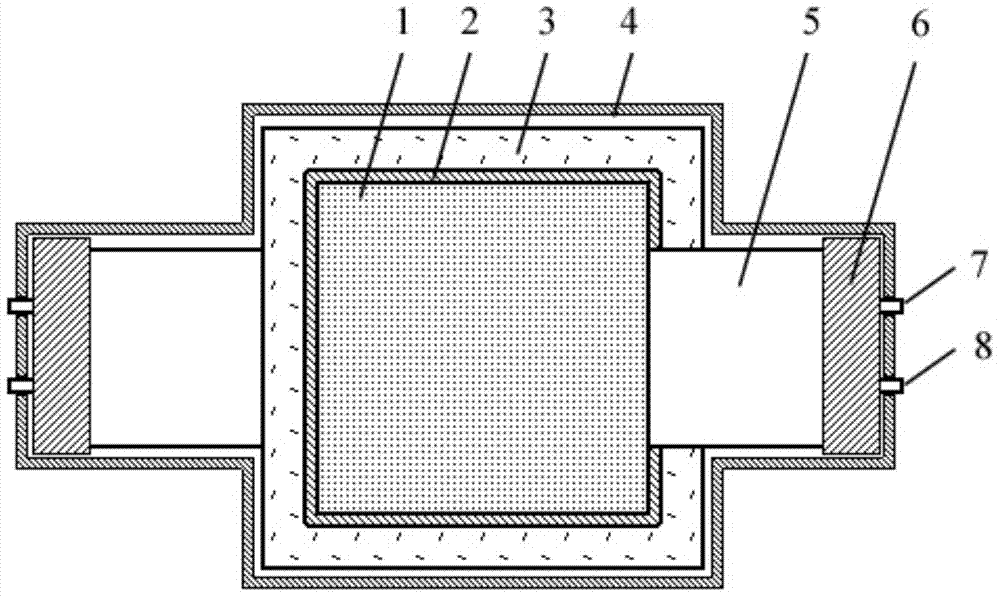

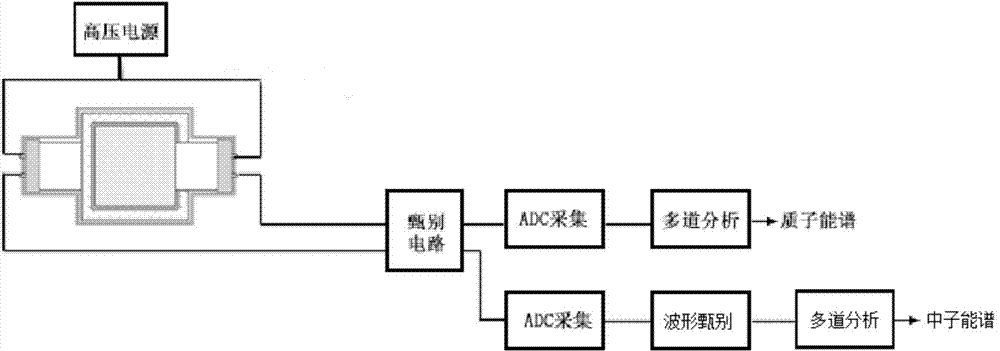

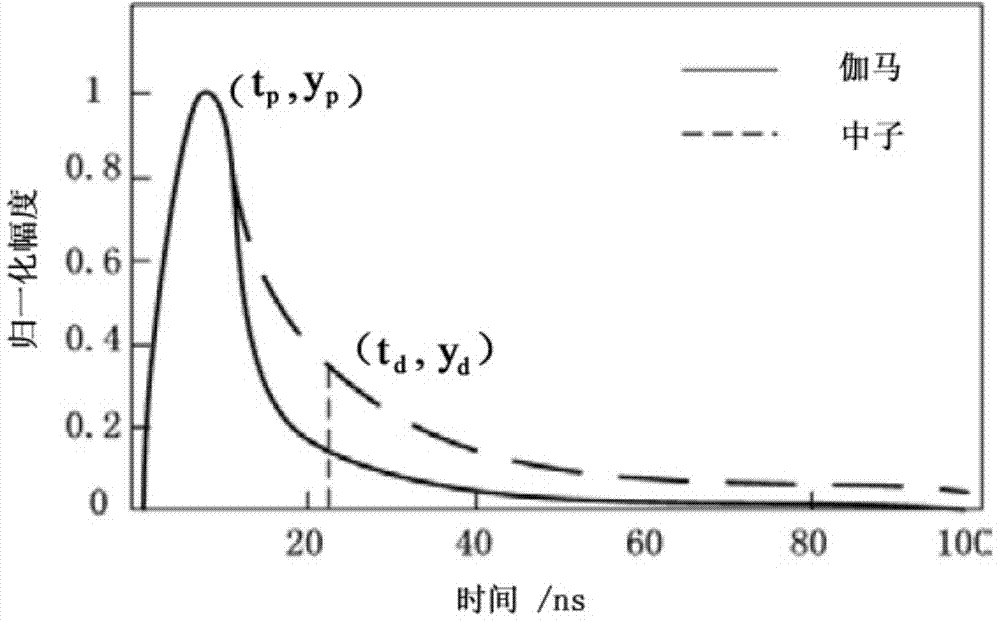

Multi-layer scintillation detector and measurement method for high-energy proton and neutron energy spectrum measurement

ActiveCN103698801AFast time responseIncrease count rateX-ray spectral distribution measurementMeasurement with scintillation detectorsNeutron energy spectrumPhotomultiplier

The invention discloses a multi-layer scintillation detector and a measurement method for high-energy proton and neutron energy spectrum measurement. The sensitive volume of the detector is formed by wrapping a scintillant with another scintillant; an interlayer is arranged between the inner layer scintillant and the outer layer scintillant; two photomultipliers are arranged on the two sides of the scintillants, and correspond to the two scintillants respectively; the interlayer is provided with a window in a position corresponding to the inner layer photomultiplier; the scintillants are pressure-welded and fixed by a housing; and the photomultipliers are fixed on the housing by photomultiplier bases. The detector can be used for the high-energy proton and neutron energy spectrum measurement under a charged particle, neutron and gamma ray complicated mixing field.

Owner:NORTHWEST INST OF NUCLEAR TECH

RF accelerator method and apparatus used in conjunction with a charged particle cancer therapy system

ActiveUS8373146B2Stability-of-path spectrometersBeam/ray focussing/reflecting arrangementsParticle radiotherapyNuclear engineering

Owner:BALAKIN ANDREY VLADIMIROVICH +1

High energy proton or neutron source

ActiveUS8837662B2Overcome disadvantagesPrevent escapeConversion outside reactor/acceleratorsDirect voltage acceleratorsHigh fluxEngineering

Owner:SHINE TECH LLC

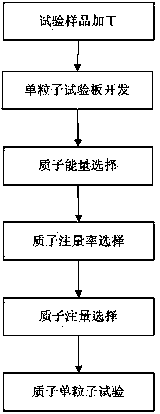

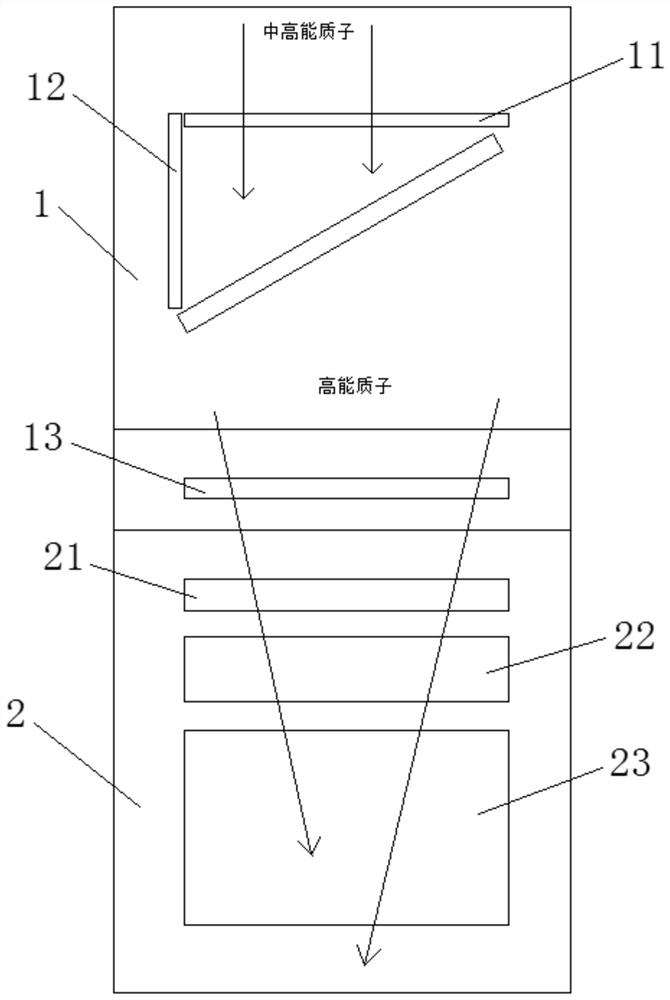

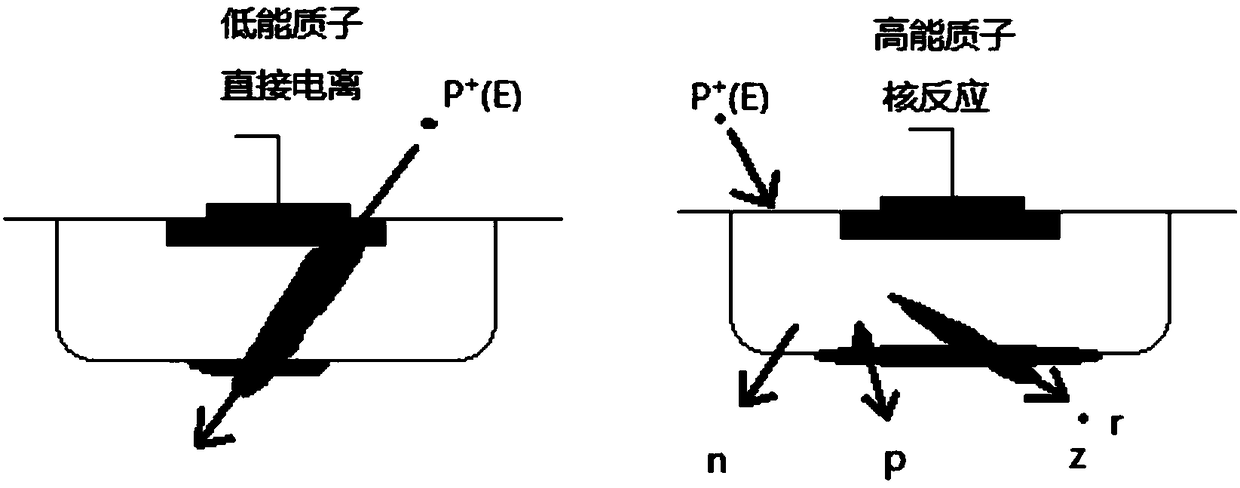

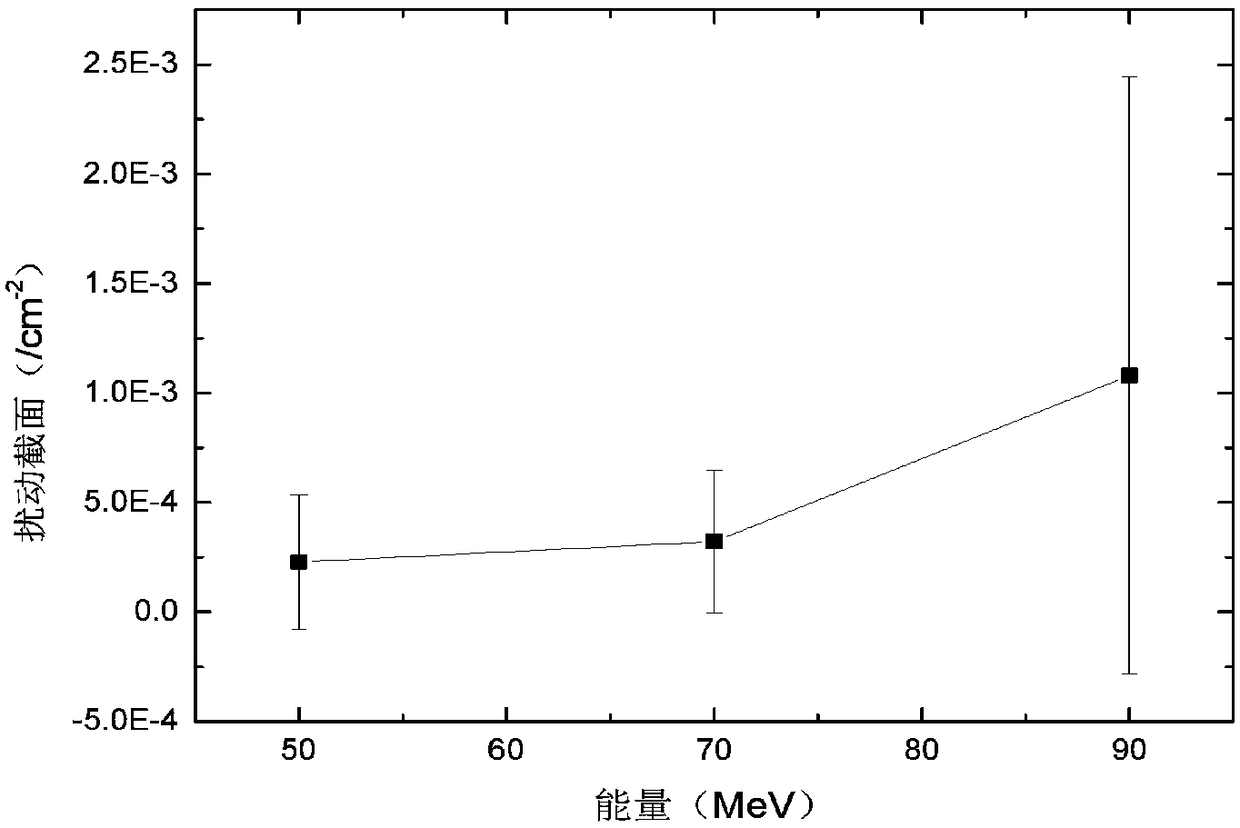

Method for conducting device proton signal-event test through accelerator high-energy proton

A method for conducting a device proton signal-event test through an accelerator high-energy proton comprises the steps that test samples are processed and the requirements of a signal-event test board and the requirements for selection of high-energy proton energy, the fluence rate and the fluence are satisfied. Single event upset of a large-scale circuit tends to be sensitive along with the increase of the integration degree and the reduction of the feature size. Single event upset can be generated through the method that a nuclear reaction of the proton occurs or the proton is directly ionized. An electronic system fault probably caused by single event upset happens to an on-orbit satellite. The method is used for conducting the device proton single event upset test on the ground. According to the method, the proton single event upset sensitivity of a key device for the satellite can be evaluated, proton single event upset sensitive parameters of the device can be obtained, a basis is provided for anti-radiation reinforcing design of the satellite, and the method for conducting the device proton signal-event test through the accelerator high-energy proton has important significance in the guarantee of the reliability of the new-generation satellite.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

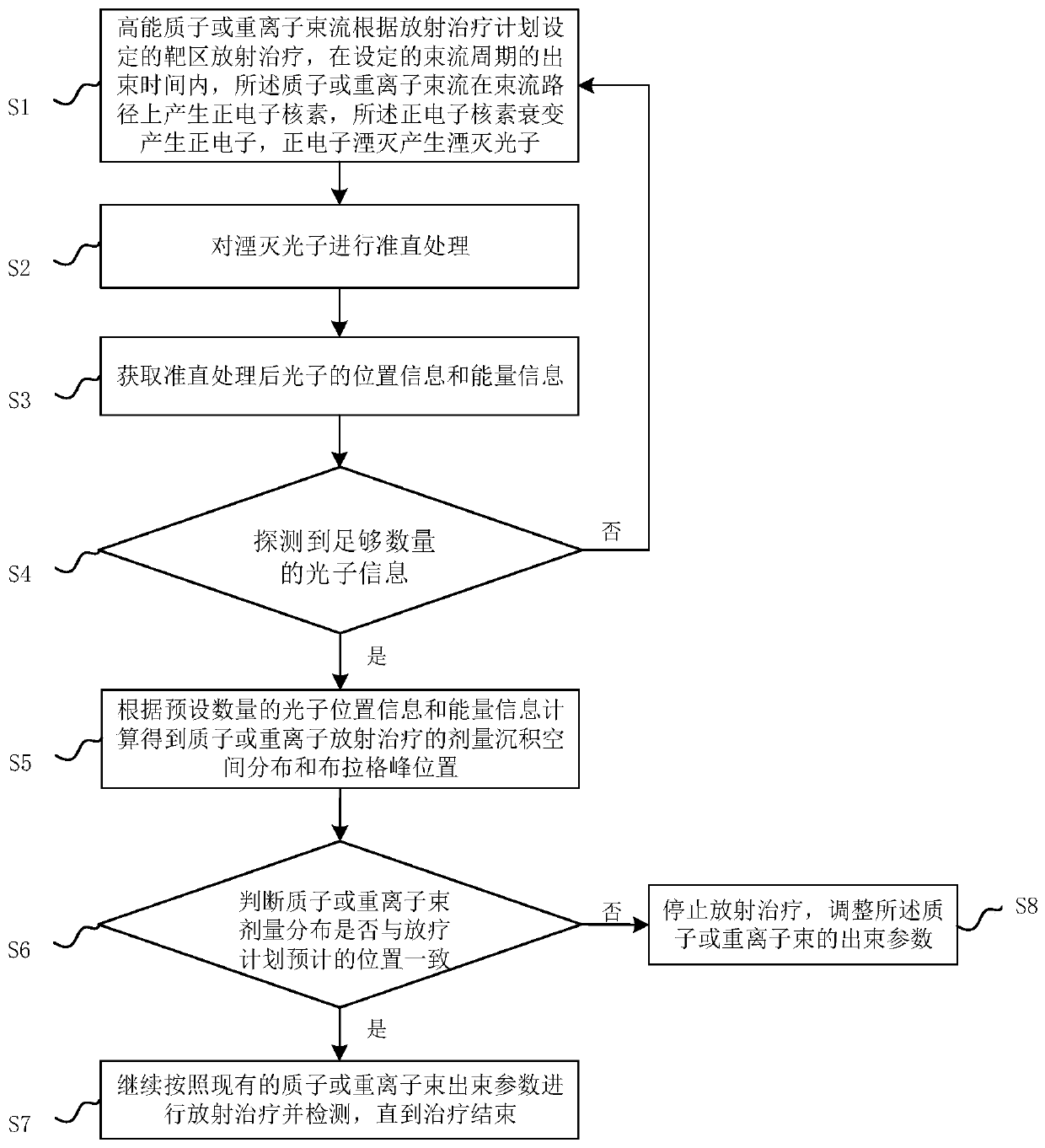

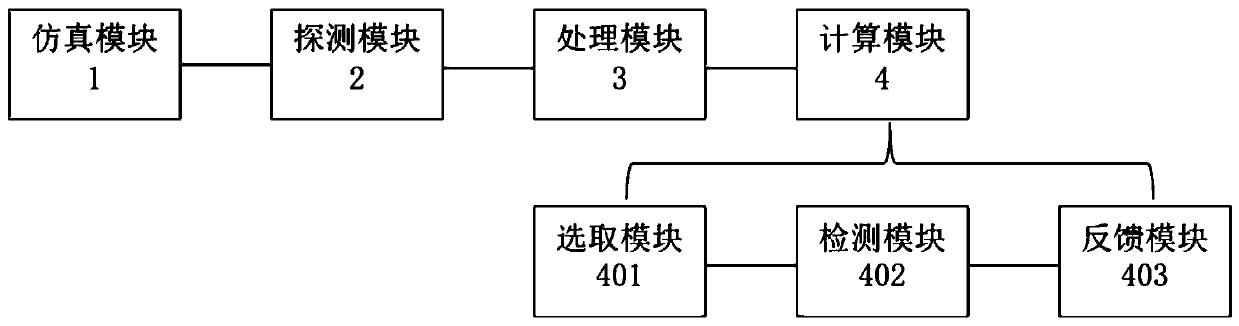

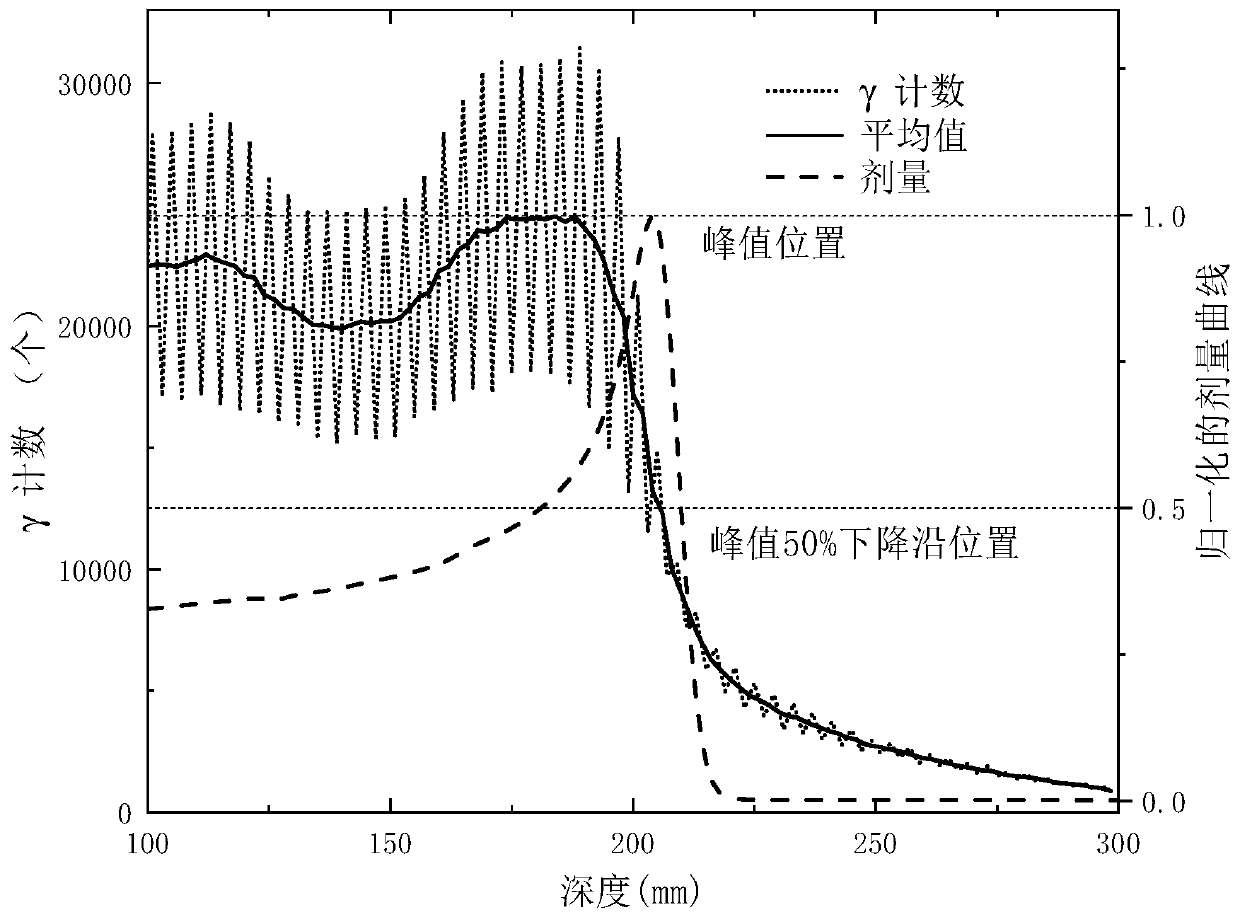

Method and system for real-time monitoring proton or heavy ion radiotherapy doses

InactiveCN110270014AHigh precisionImprove detection efficiencyX-ray/gamma-ray/particle-irradiation therapyHeavy particleHeavy Ion Radiotherapy

The invention relates to a method and a system for real-time monitoring proton or heavy ion radiotherapy heavy particle radiotherapy doses. The monitoring method utilizes distribution information of positron radionuclide produced during the high-energy proton or heavy ion radiotherapy, and measures position and energy information of annihilation photons in the intermittent time of beams according to beam cycles of protons or heavy ions to obtain dose deposition spatial distributions in the proton or heavy ion radiotherapy, thereby realizing the monitoring of dose distributions of proton or heavy ion beams. Compared with the traditional instantaneous gamma measurement method, the method has a higher detection efficiency, and the method effectively reduces statistical noise, and improves accuracy of the dose deposition of the proton or heavy ion radiotherapy; compared with the traditional positron emission tomography method, the method can realize a faster one-dimensional distribution of dose along the beam direction by carrying out a collimation treatment on the annihilation photons along the beam direction and then detecting the position and energy information of the photons, thus the method is conducive to improving monitoring efficiency.

Owner:彭浩

3HE fusion device with direct electrical conversion

Owner:WILSON GREATBATCH LTD

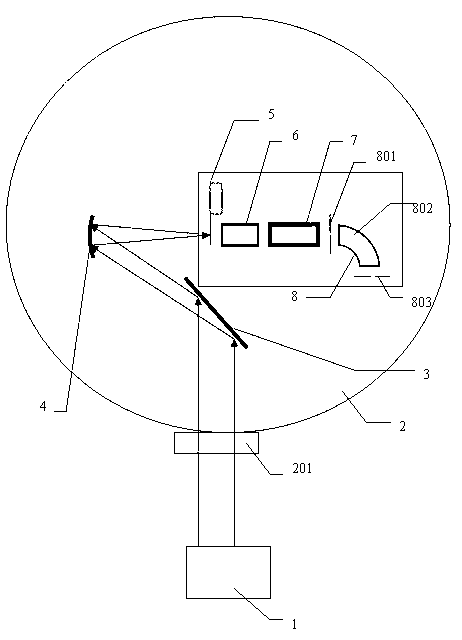

Photo-anode proton source

ActiveCN103310865ASmall beam emittanceSmall sizeRadioactive sourcesHigh Energy Density MatterHigh energy

The invention discloses a photo-anode proton source which is suitable for high-resolution proton photographing, proton diagnosis and treatment, and generation of high-energy density matters, and is used as an injector of a high-energy proton accelerator. The photo-anode proton source comprises a laser light source and a vacuum target chamber. An ultrashort ultrastrong laser beam irradiates on a planar mirror in the target chamber by penetrating a vacuum target chamber window; the reflected laser beam is focused on a hydrogen-enriched magnetic tape target by an off-axis parabolic reflection focusing mirror, so as to generate an MeV-order continuous spectrum proton beam; energy spectrums and divergence angles of the proton beam can be improved through a back beam current quality adjustment system; collimation of the beam current can be realized by utilizing a solenoid; the energy spectrum of the collimated beam current can be modulated after the collimated beam current passes through an RF (radio frequency) chamber to generate a series of quasi energy peaks; and finally the beam current passes through an energy selection system with a slit-bending iron-slit structure to generate a needed single energy proton beam. The photo-anode proton source is simple in structure, and has good collimation, monochromaticity and stability.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

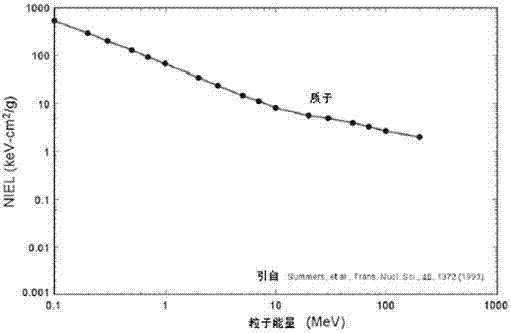

Method for carrying out spatial displacement damage effect evaluation test through high energy protons

InactiveCN104297585AFacilitate engineering developmentThe assessment results are accurateElectrical testingHigh energyPeak value

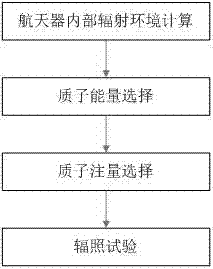

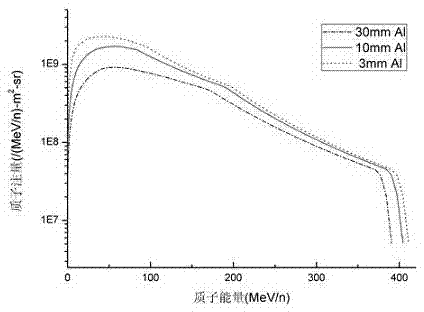

The invention relates to a method for carrying out a spatial displacement damage effect evaluation test through high energy protons. The method includes the following steps that firstly, internal radiation environment of a spacecraft is calculated, space environment effect calculation software is used, track parameter values of the earth track spacecraft, a space radiation environment model, the shielding thickness of the spacecraft are input, and the internal proton differential energy spectrum of the spacecraft is calculated; secondly, the protons are selected, the worked-out internal proton differential energy spectrum of the spacecraft in the track has a proton fluence peak value as the protons are not evenly distributed along with energy, and the energy proton corresponding to the fluence peak value is selected as the proton for the evaluation test; thirdly, the proton fluence phi(EI) for the test is calculated; fourthly, the radiation test is carried out, and the energy protons determined through calculation are used for radiating an element to the specified fluence. After radiation, the electricity test is carried out according to product standards and requirements.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

Method for verifying single particle soft error protection design based on heavy ion accelerator

ActiveCN105866573AReduced need for testingReduce design and development costsElectrical testingHeavy ion radiationHeavy ion irradiation

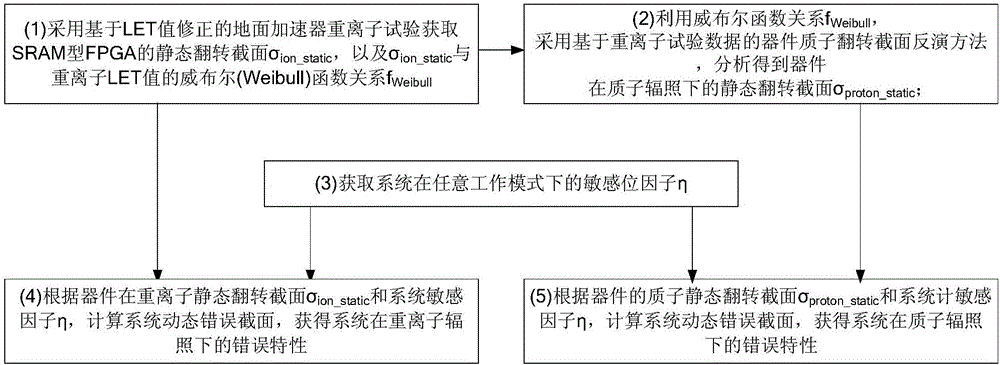

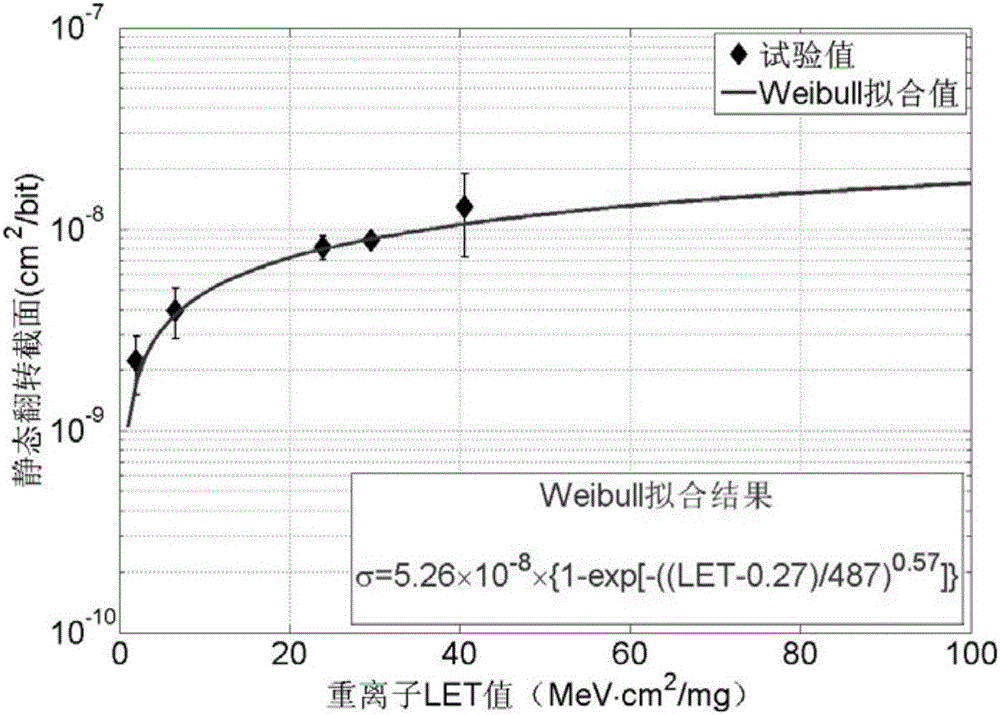

The invention discloses a method for verifying a single particle soft error protection design based on a heavy ion accelerator, and relates to the field of heavy ion and proton equivalent test verification of system single particle protection effect verification based on accelerator test data. The method includes the following steps: (1) adopting a ground accelerator heavy ion test which is determined on the basis of a LET value; (2) analyzing a proton static overturning cross section; (3) analyzing a sensitive bit factor of the system under any working mode; (4) analyzing a dynamic overturning cross section of the system under heavy ion radiation; (5) analyzing a dynamic overturning cross section of the system under proton radiation. The invention provides a method for verifying a single particle soft error protection design based on the heavy ion accelerator. The method can be intended for verifying single particle protection effects, and address the problems of tight time of domestic accelerators and difficulty in realizing high energy proton tests.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

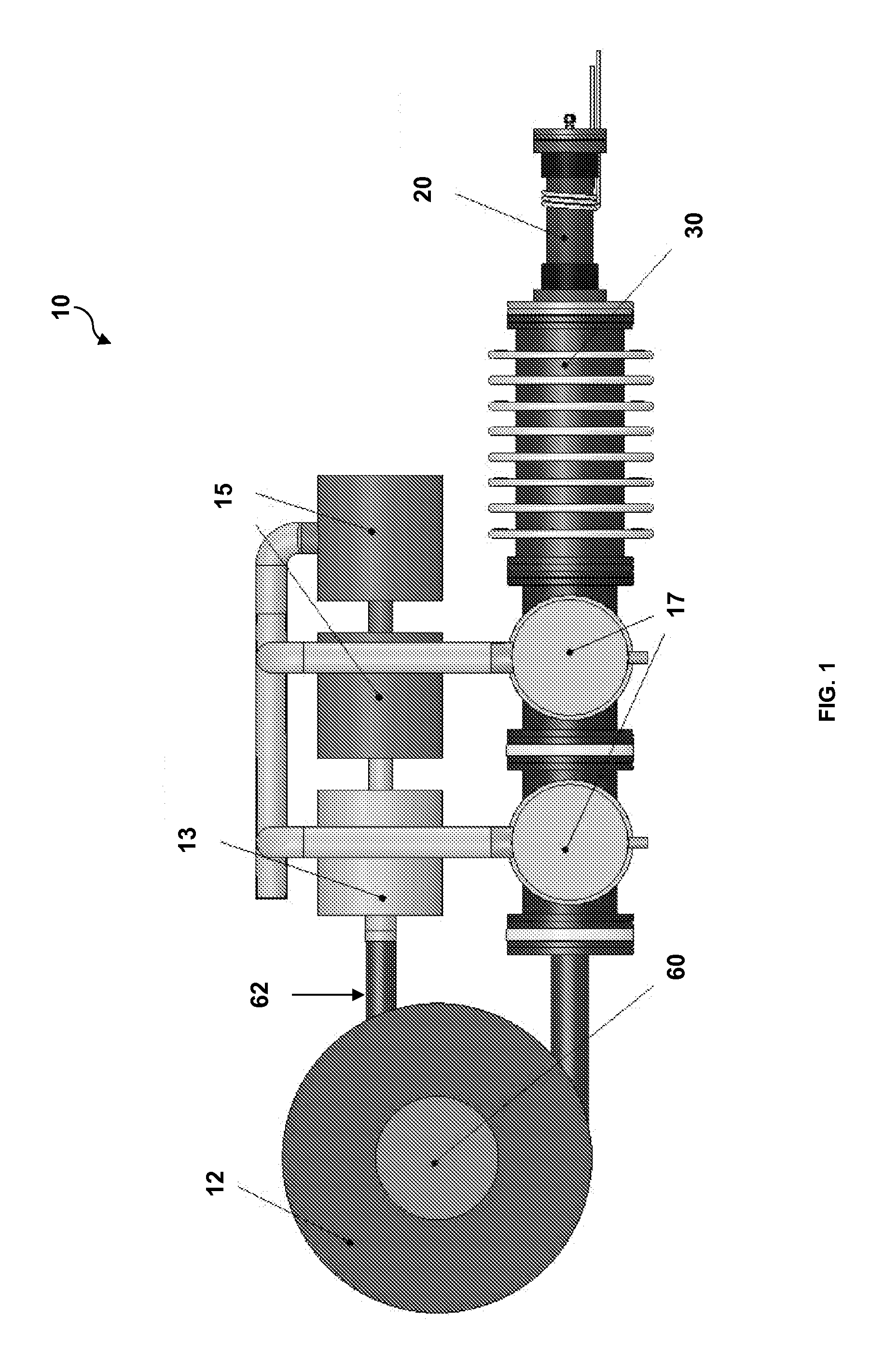

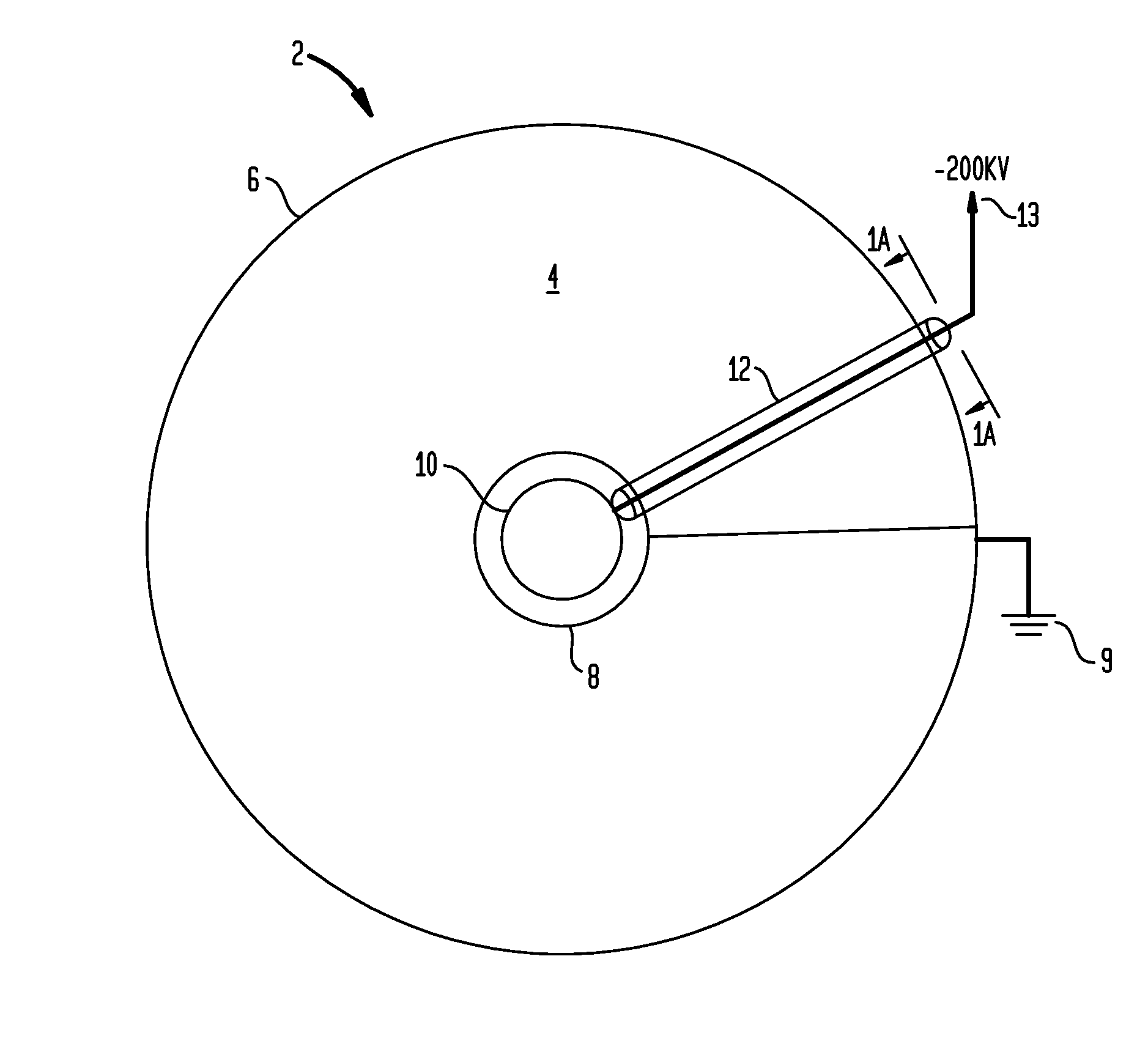

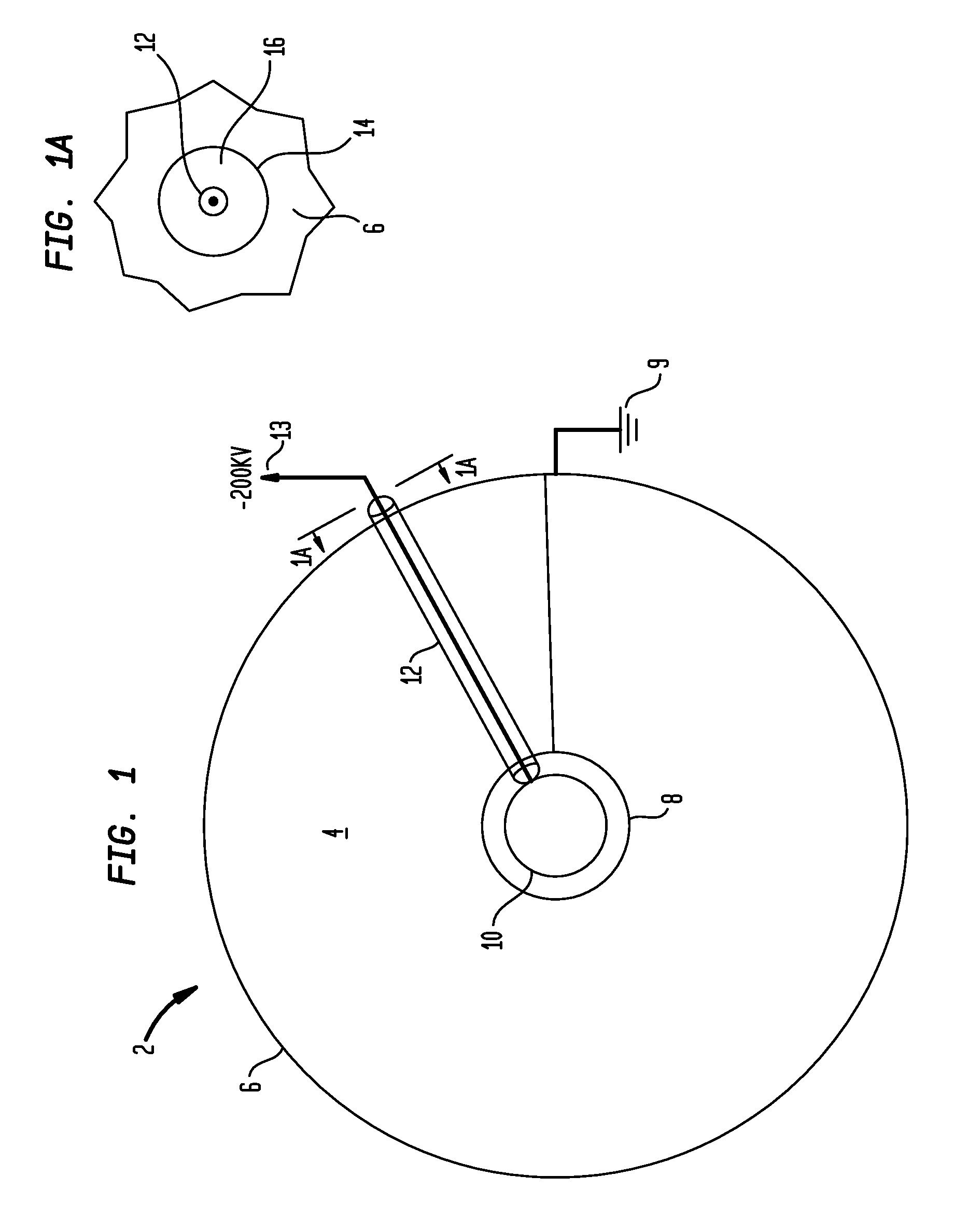

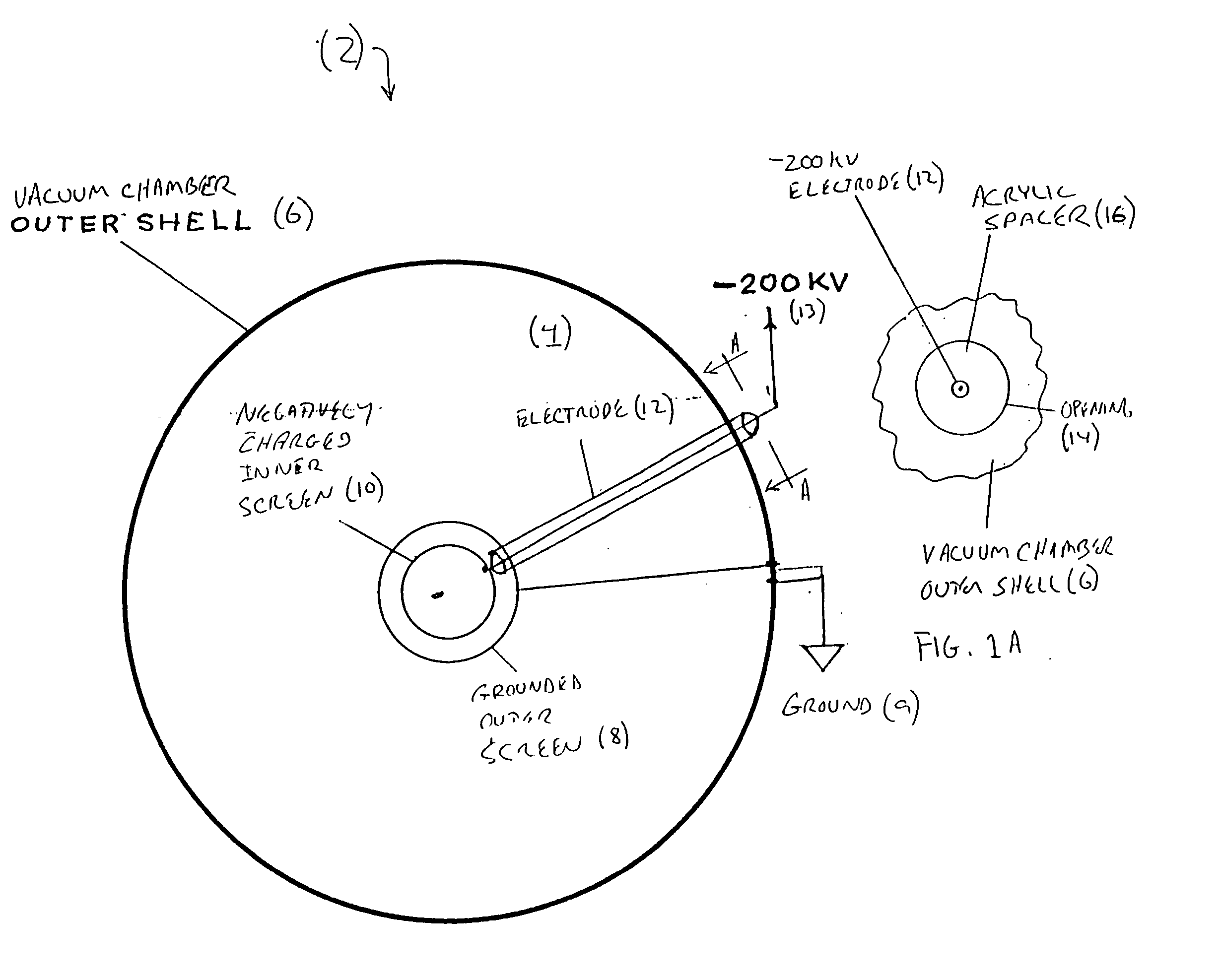

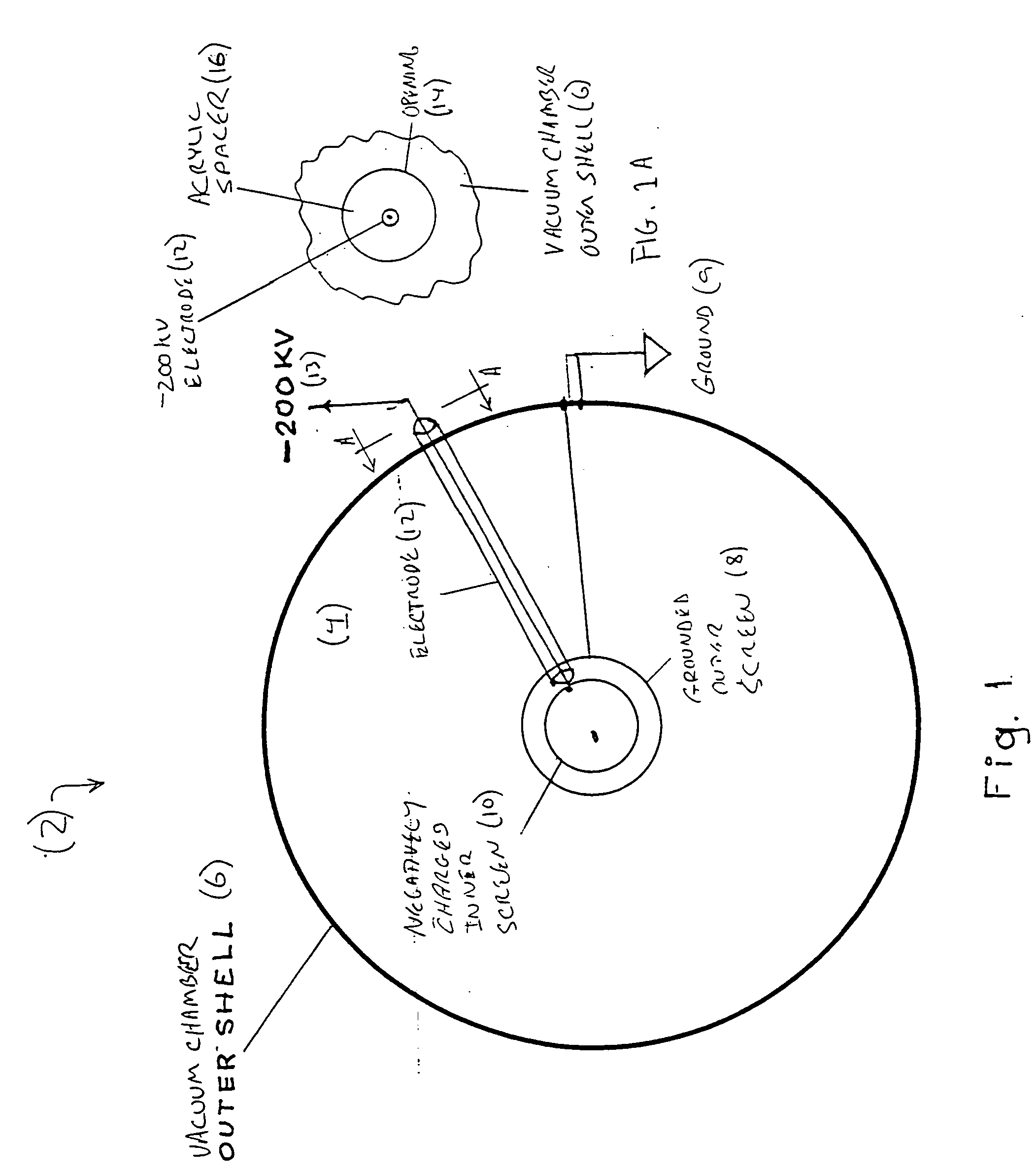

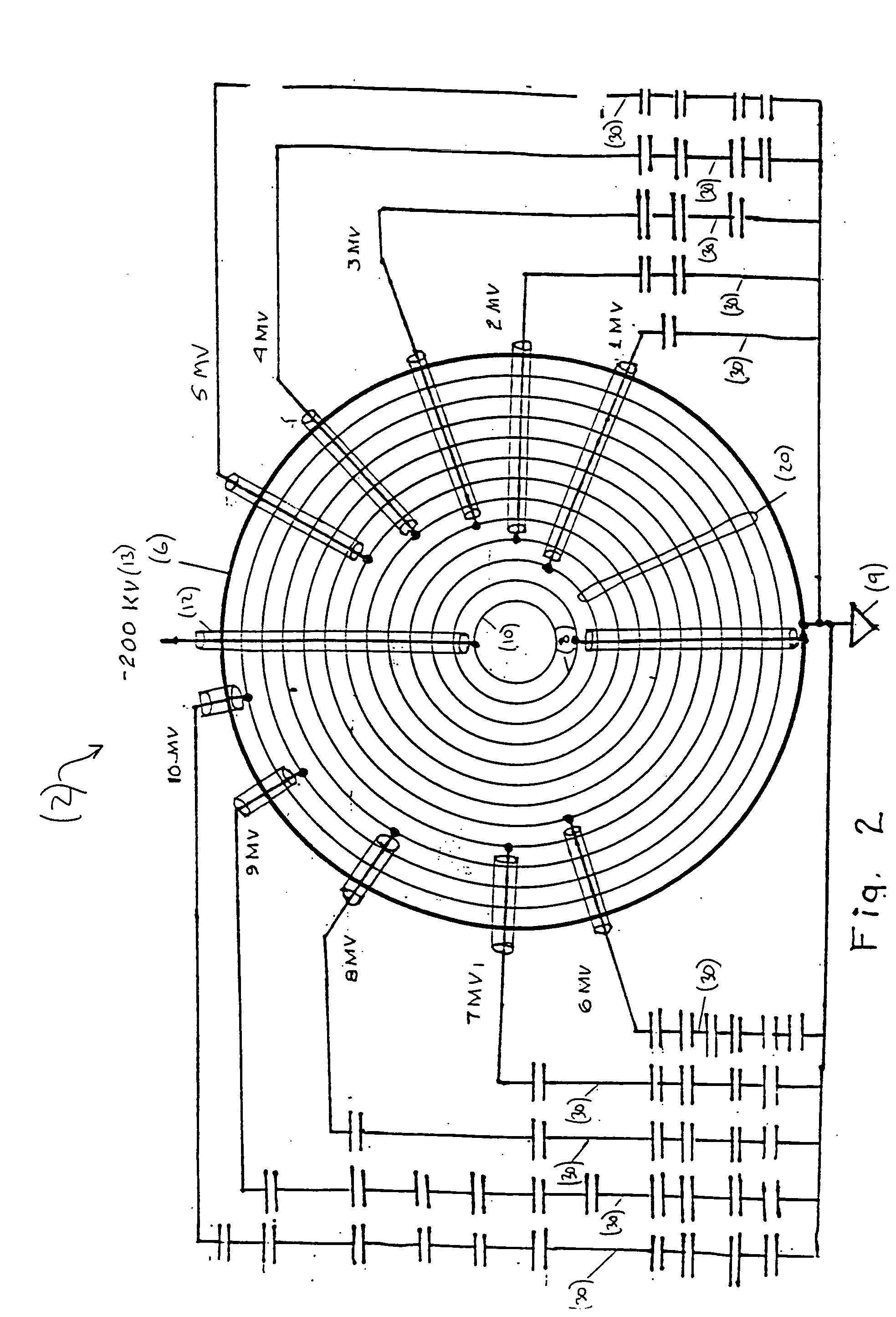

3He reactor with direct electrical conversion

InactiveUS20050220243A1Long air leakage pathSpark suppressionNuclear energy generationDirect voltage acceleratorsPotential wellEngineering

An improved 3He nuclear reactor with provision for direct electric conversion of a relativistic proton stream into useable electric power at a voltage level compatible with the national power grid (one million V DC). Various embodiments include multiple collector cages for extracting relativistic protons of various energy levels, diverter wires for deflecting high-energy proton streams to either side of lower energy cages to avoid unwanted impact. Other embodiments include arrangements for dividing multi-megavolt voltages down to a useable one megavolt level compatible with the national power grid. Further embodiments comprise guiding the proton stream by the cusps of magnetron cavities to permit conversion of the relativistic proton energies into microwave power. A proposal is also made for harvesting 3He from the Moon to supply earth-bound and space-bound reactors. A solution to the problem of charging a potential well-forming anode in an electrostatic fusion reactor without electrical arcing is further disclosed.

Owner:WILSON GREATBATCH LTD

High-energy proton beam density distribution testing device

InactiveCN106646578ALittle impact from external disturbancesElectrostatic dosimetersElectrometerMulti dimensional

The invention relates to the technical field of proton adsorbed dose research, and specifically relates to a high-energy proton beam density distribution testing device. The device comprises a vacuum cavity, a Faraday cup, a multi-dimensional moving platform, a shielding box and a static electrometer, wherein the Faraday cup is fixed in the vacuum cavity through the multi-dimensional moving platform, and is enabled to be opposite to a proton beam in the vacuum cavity. The Faraday cup is connected with the input end of the static electrometer in the shielding box, and a grounding end of the static electrometer and the Faraday cup are connected with a side wall of the vacuum cavity through grounding lines. A motor controller in the shielding box is connected with the multi-dimensional moving platform, and can control the multi-dimensional moving platform to move. The device provided by the invention can test the density distribution of the high-energy proton beam in the vacuum cavity, and can achieve the comprehensive assessment of a charge environment in an electronic sample room. The impact on the device from the external interference is small, and the device can effectively detect the density distribution of the high-energy proton beam.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

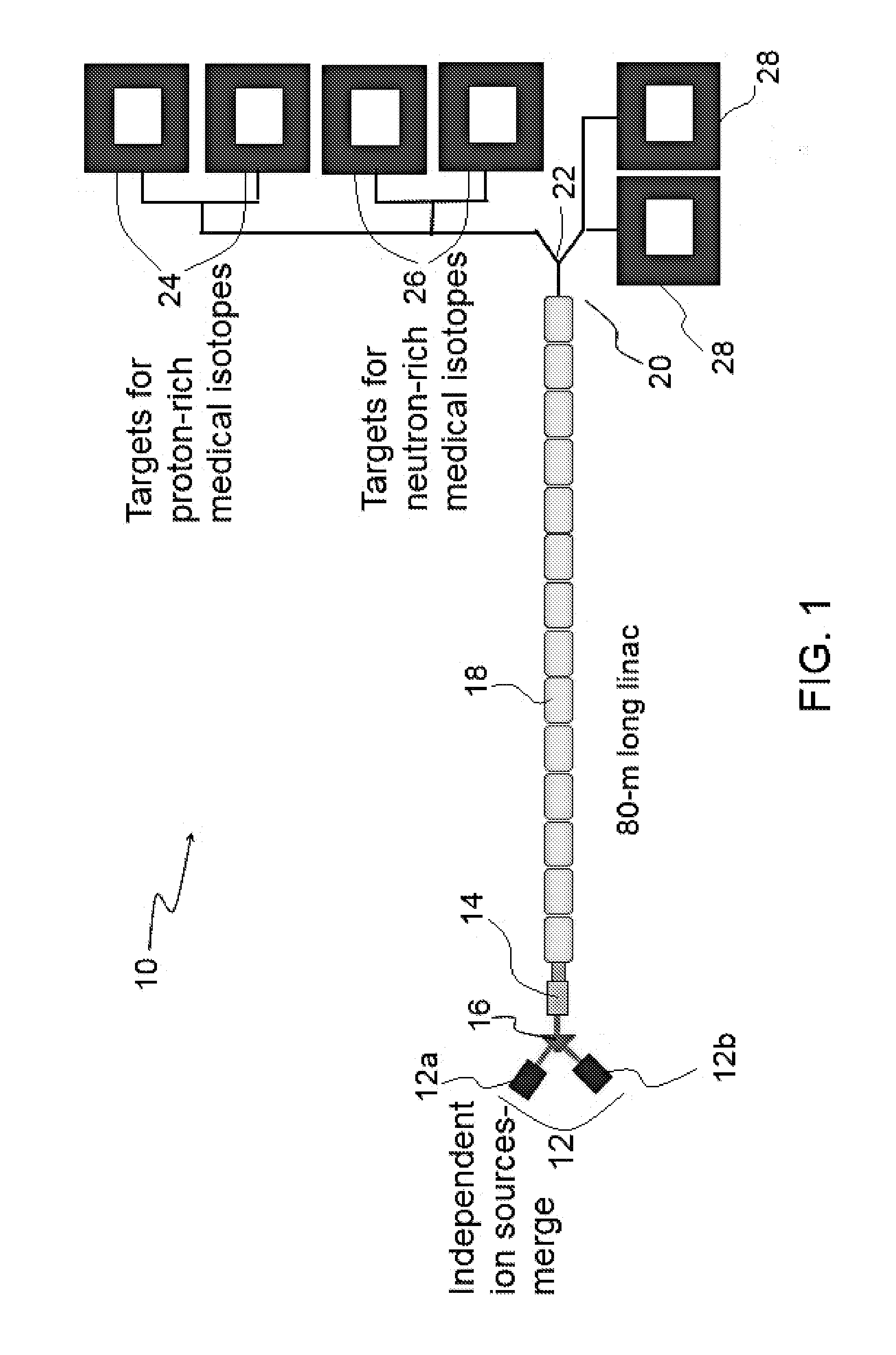

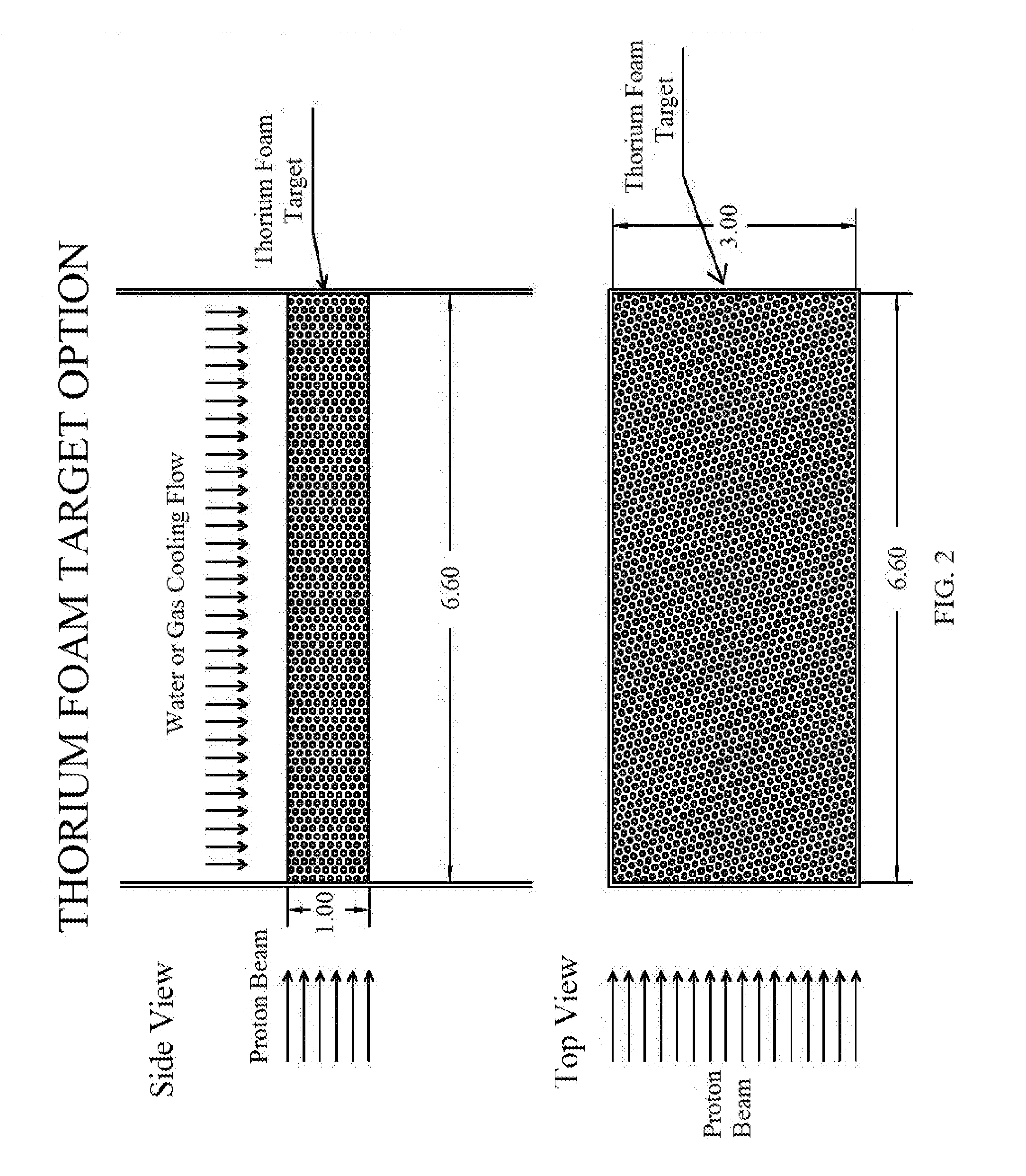

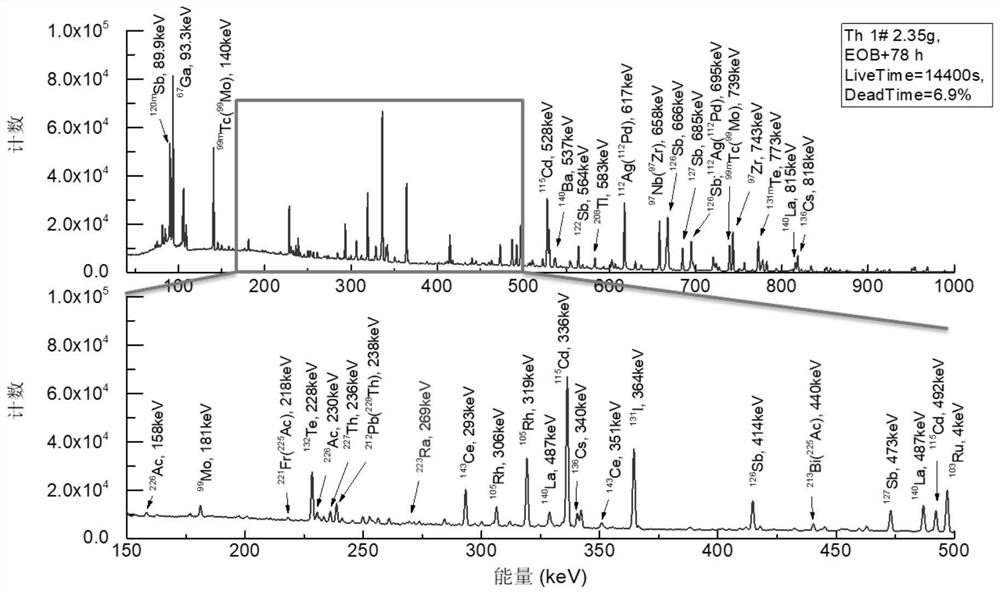

Production of isotopes using high power proton beams

ActiveUS20160111176A1Efficient extractionIncrease productionSpecific isotope recoveryConversion outside reactor/acceleratorsDecay productParticle beam

The invention provides for a method for producing isotopes using a beam of particles from an accelerator, whereby the beam is maintained at between about 70 to 2000 MeV; and contacting a thorium-containing target with the particles. The medically important isotope 225Ac is produced via the nuclear reaction (p,2p6n),whereby an energetic proton causes the ejection of 2 protons and 6 neutrons from a 232Th target nucleus. Another medically important isotope 213Bi is then available as a decay product. The production of highly purified 211At is also provided.

Owner:UCHICAGO ARGONNE LLC

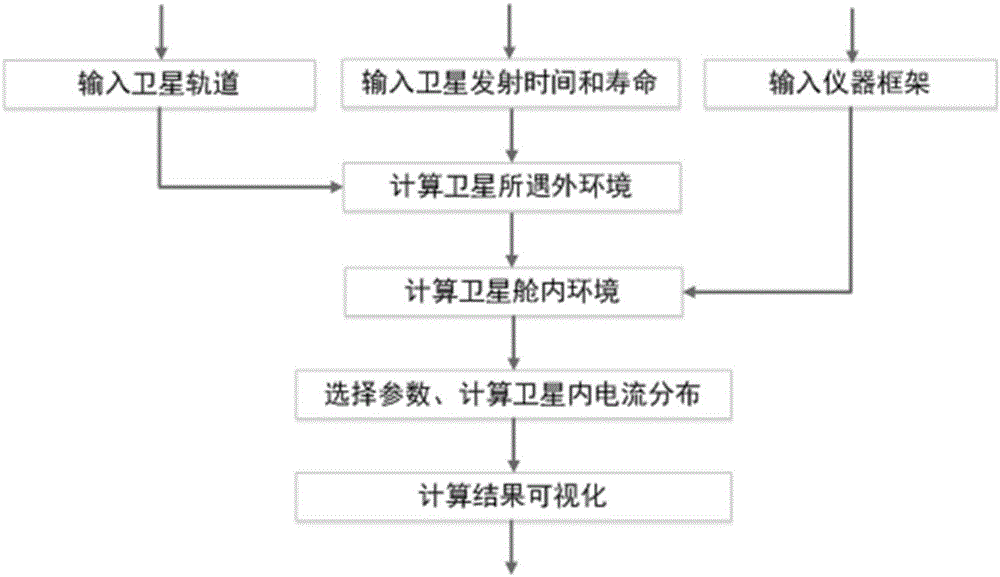

Method for assessing deep charging and discharging risks of satellite

The invention provides a method for assessing deep charging and discharging risks of a satellite. The method comprises the following steps: step one, acquiring a flight track of the satellite; step two, acquiring launch time and designed service life of the satellite; step three, acquiring mechanical frames of the satellite and an instrument and types of dielectric materials; step four, calculating an external environment of the satellite by using a Tiamotech tool, wherein the external environment of the satellite comprises high-energy electrons and high energy protons; and step five, using parameters of a simulating tool material library and selecting or inputting the parameters, and calculating dielectric current in the satellite so as to finish deep charging simulation of the satellite at a targeted position; and step six, visualizing a calculating result by using the Tiamotech tool. A series of problems of contradiction between assessment precision and assessment machine-hour in an operational assessment process of radiation effect hazards of the satellite in a spacecraft researching process are solved. By the method, assessment on satellite deep charging and discharging caused by a space radiation environment is realized.

Owner:SHANGHAI SATELLITE ENG INST

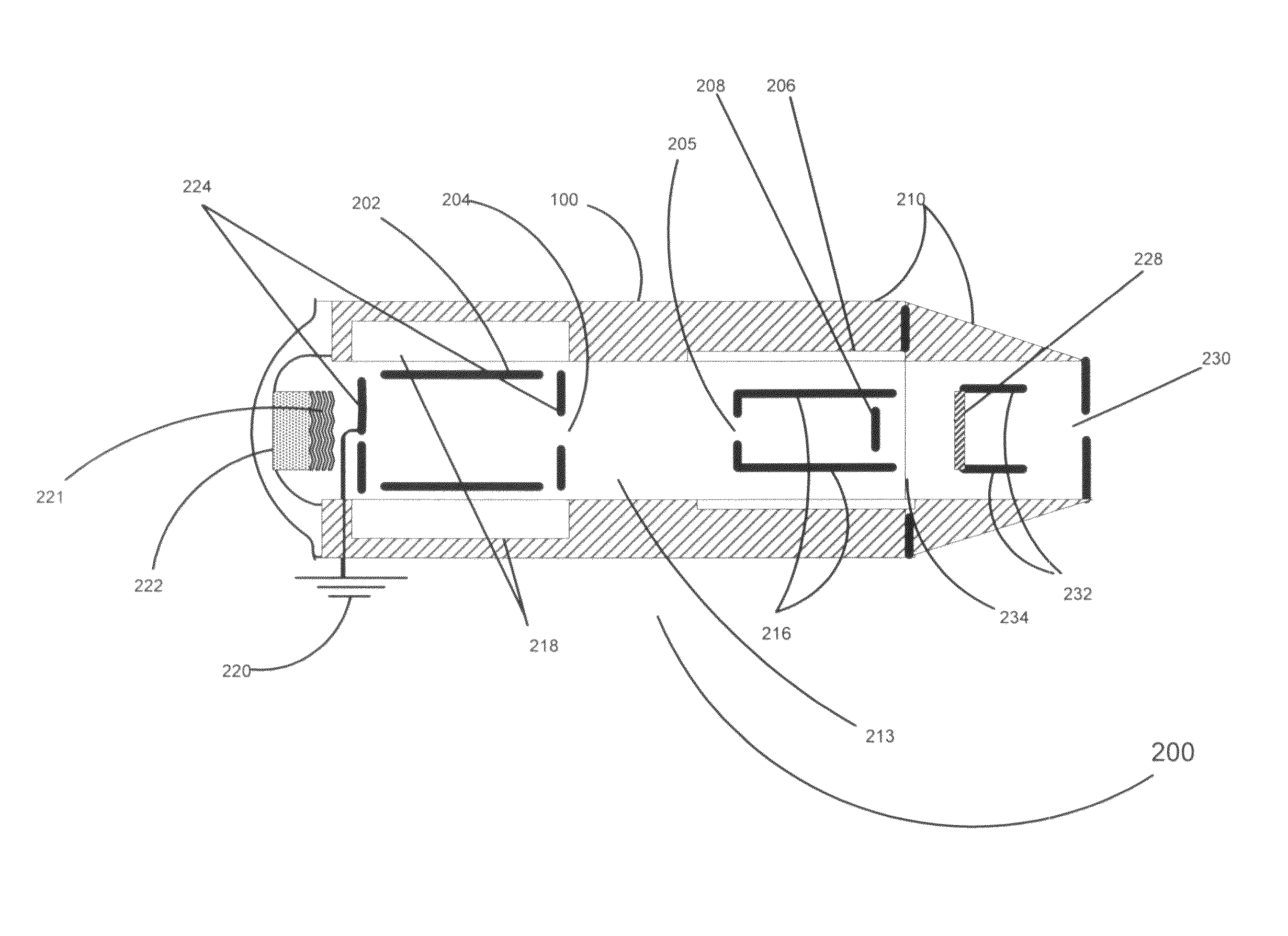

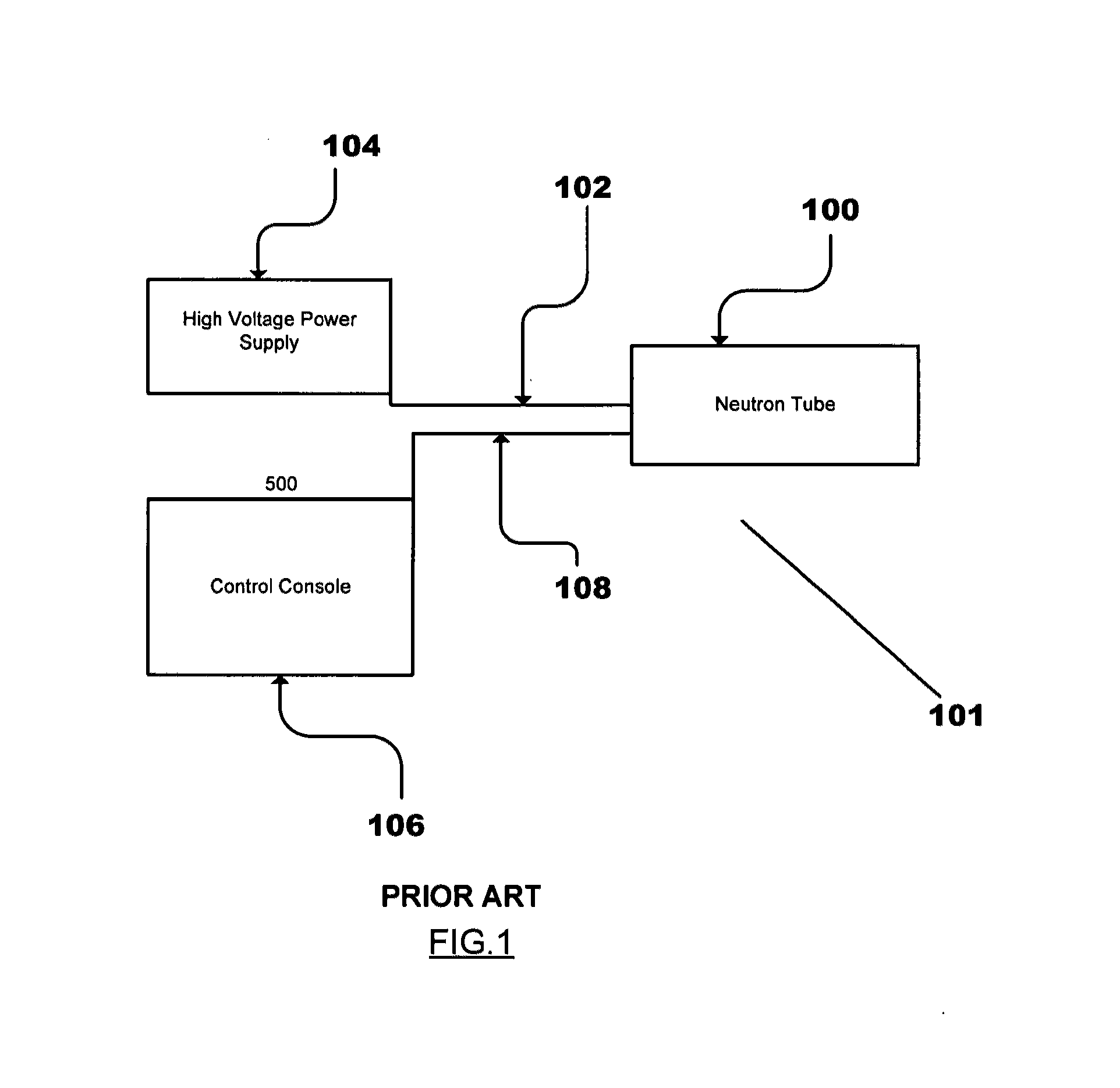

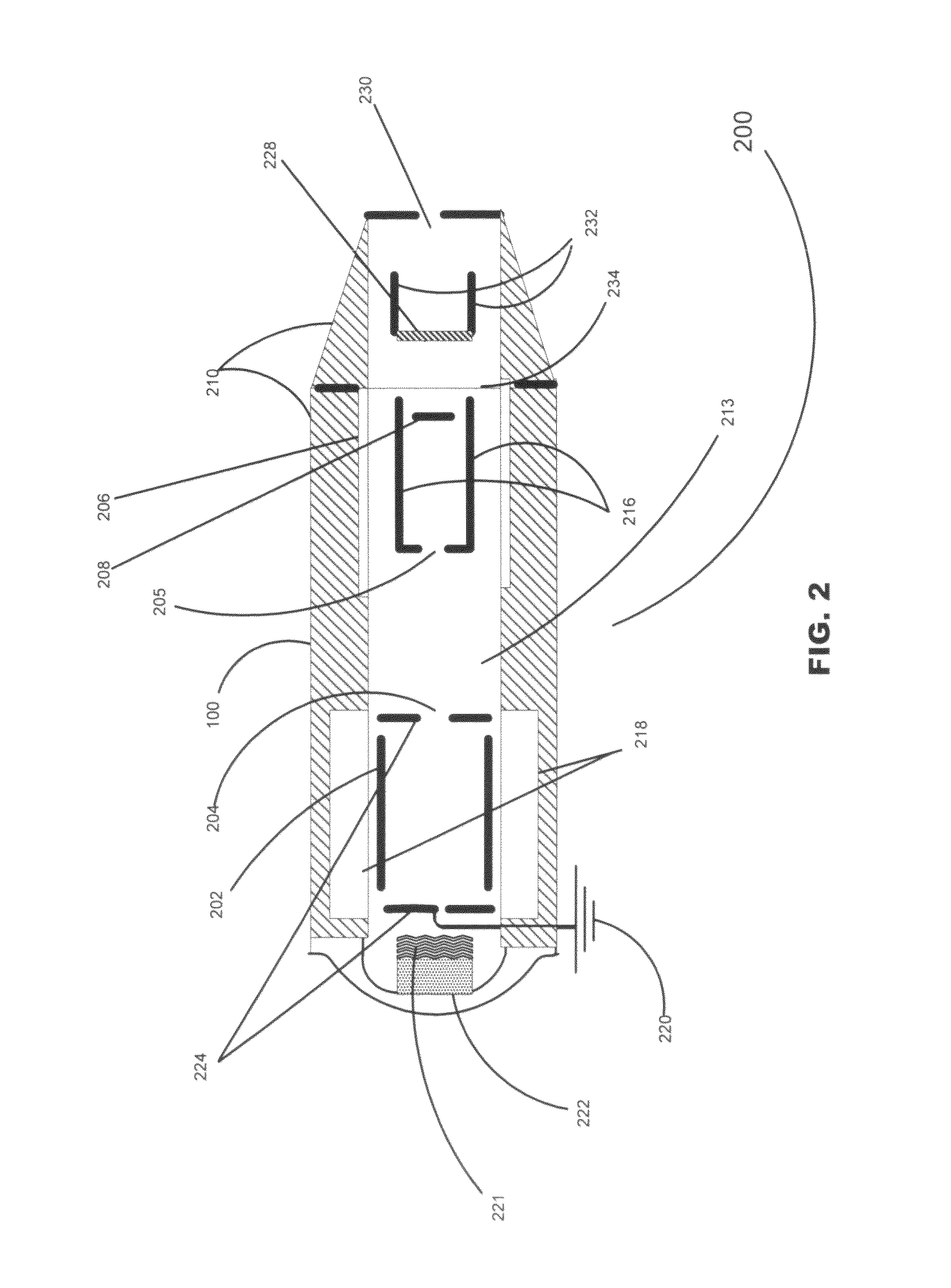

Method and apparatus for destroying pathogenic bacteria

InactiveUS8357329B1High kill rateMinimize damageConversion outside reactor/acceleratorsNuclear energy generationPathogenic microorganismNeutron emission

An apparatus for destroying bacteria is provided which includes a neutron generator and a target polymer film which will receive the impact of neutron emissions. Neutrons impacting the target film produce a second emission of high energy protons which are made to move through an electromagnetic field external to the neutron tube thereby accelerating and steering a generated proton spray. This embodiment is well-suited for treating physical locations known to be infected by pathogenic microorganisms.

Owner:SYSTEM PLANNING CORPORATION

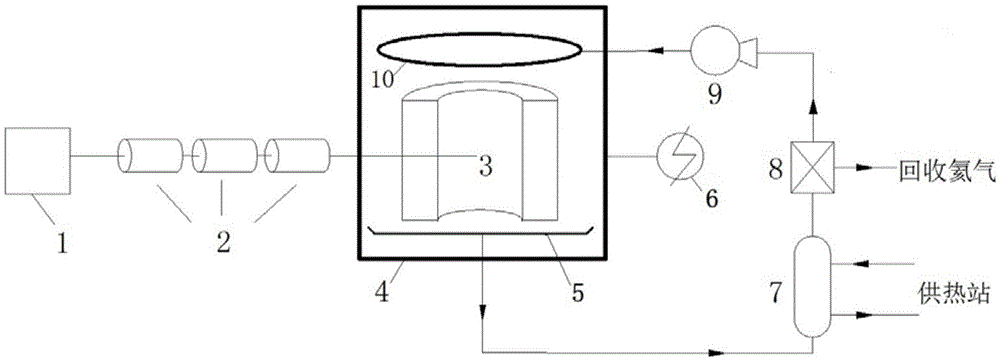

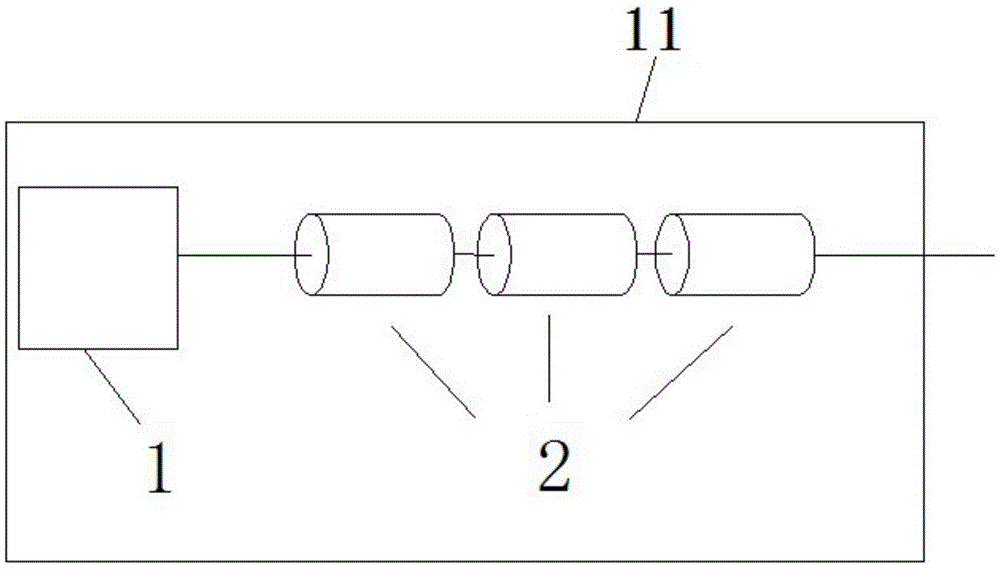

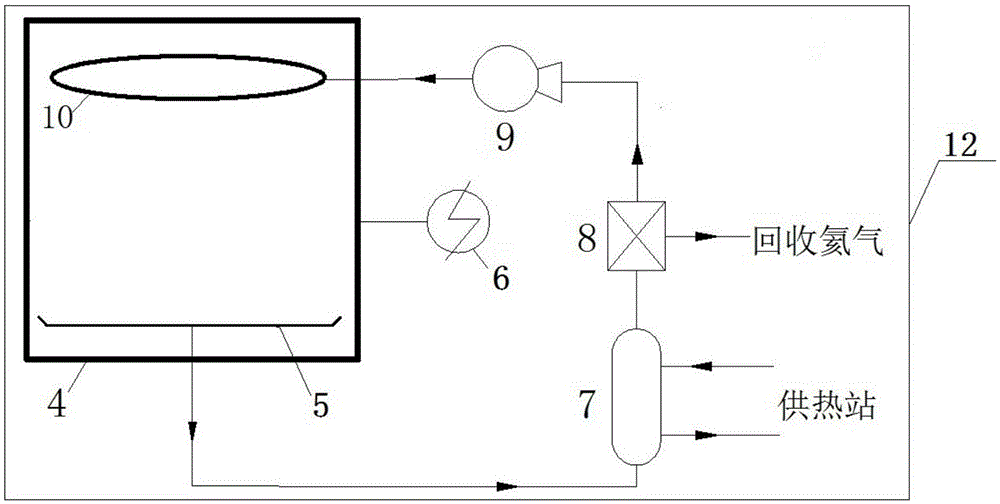

Accelerator-driving proton-boron fusion nuclear device

ActiveCN105609145AReduced shieldingLower requirementNuclear energy generationThermonuclear fusion reactorHigh energyFusion power

The present invention discloses an accelerator-driving proton-boron fusion nuclear device which is mainly formed by an accelerator system, a boron target and an energy conversion system. By using an accelerator, the energy of a proton is accelerated to energy threshold needed by the generation of a proton-boron fusion reaction, the high energy proton bombards the boron target and a proton-boron reaction is generated, and finally the energy conversion system brings energy out. Compared with a conventional magnetic confinement deuterium and tritium fusion reaction device, the proton-boron fusion nuclear device has the advantages that on one hand the generation of a high energy neutron can be avoided, the radiation damage to a structural material by the neutron is effectively excluded, and the requirements of biological shielding and remote operation safety are reduced, on the other hand, the existing mature proton accelerator technology can be used, and the realization of fusion energy is accelerated.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

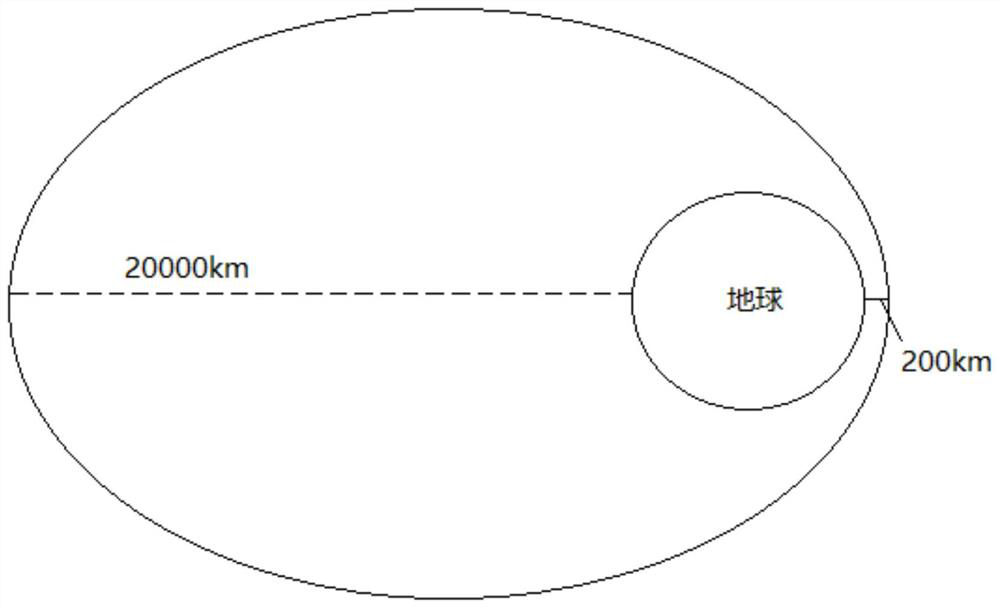

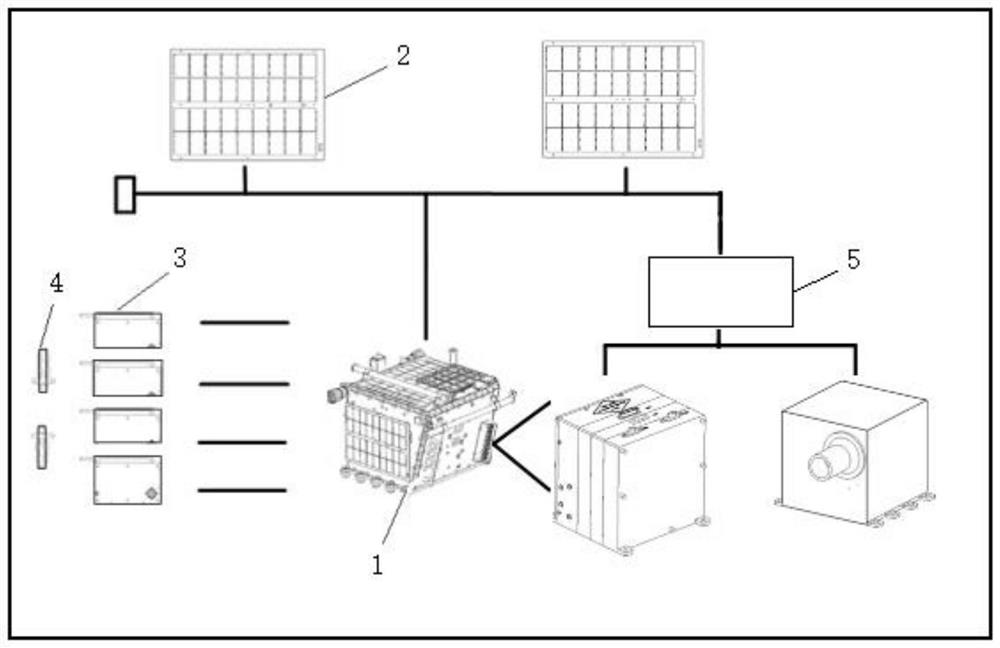

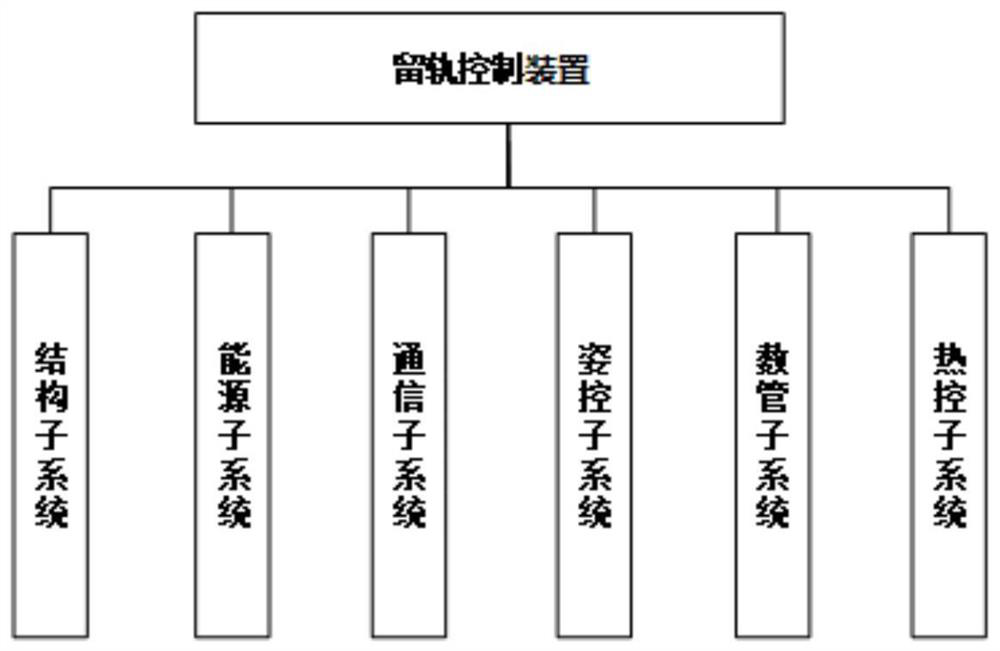

Space environment comprehensive monitoring system based on rail remaining tail sub-level

PendingCN114136366AHigh cost-effectiveIncrease the areaMeasurement devicesNeutral atmosphereLoad carrying

The invention discloses a space environment comprehensive monitoring system based on an orbit remaining tail sub-level, and aims to solve the problems of scarce opportunities, high cost and the like of space environment monitoring load carrying on a space environment research satellite and a general service satellite in the prior art. The method comprises the following steps of: monitoring a load by using a rail-leaving tail sub-stage of a preset rail-leaving control platform and a space environment loaded on the rail-leaving tail sub-stage based on a large elliptical rail formed after passivating and discharging the rail-leaving tail sub-stage; high-energy proton measurement, single event effect monitoring and radiation dose measurement of different orbit heights and earth neutral atmosphere density monitoring of which the perigee height of a large elliptical orbit is in a near space orbit range are carried out, and obtained monitoring data are used for fault analysis of a spacecraft and precise orbit forecasting of the spacecraft. The novel space environment comprehensive monitoring system is high in cost-effectiveness ratio, short in task period, wide in track coverage and distributed in bearing, and large-area, real-time, synchronous, multi-scale and multi-element space environment information can be obtained.

Owner:NO 63921 UNIT OF PLA

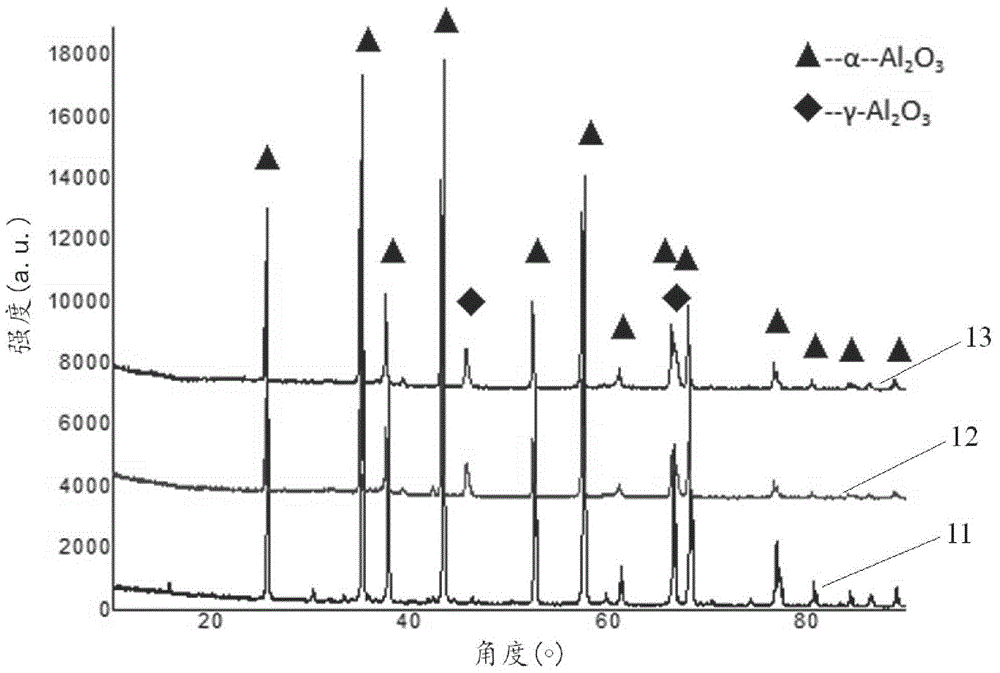

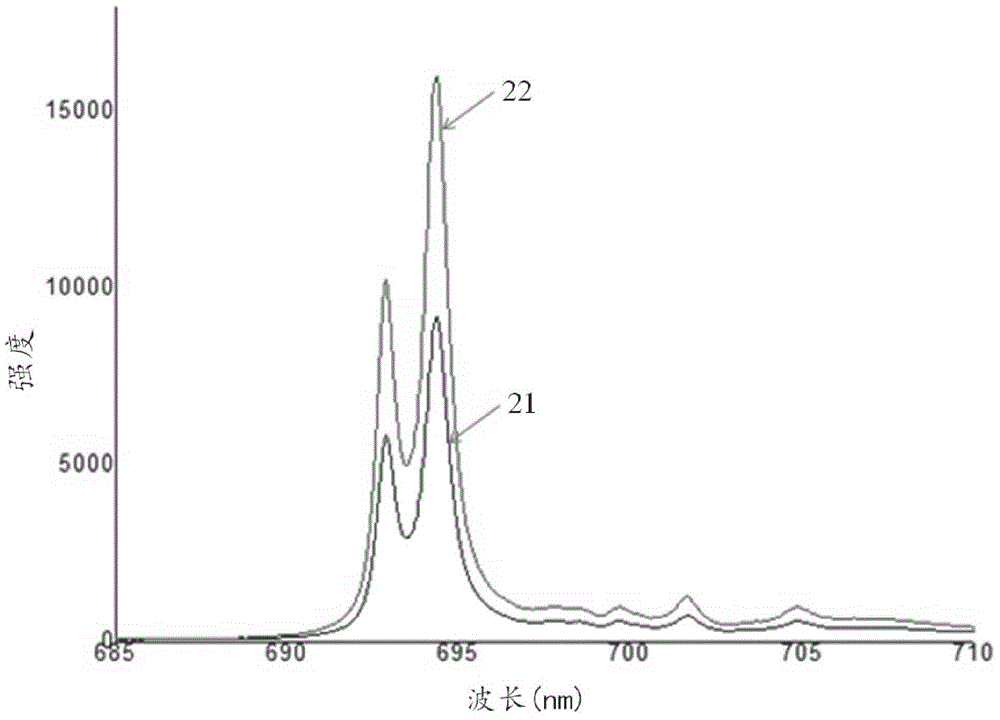

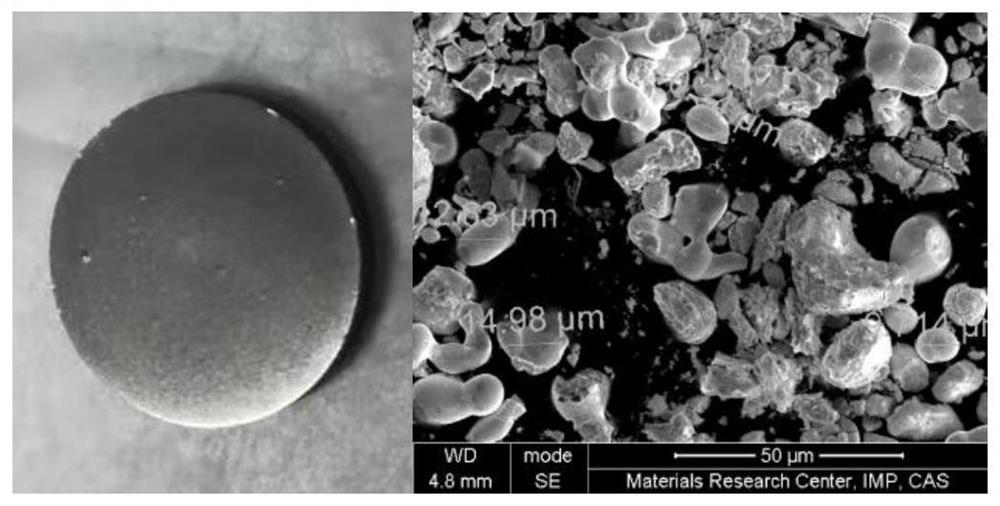

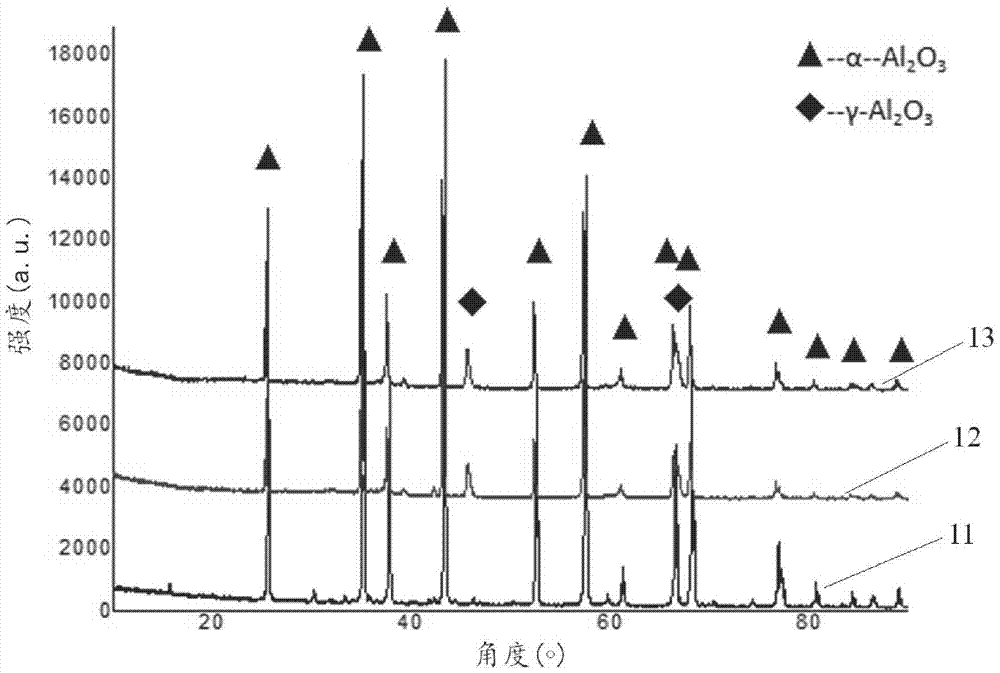

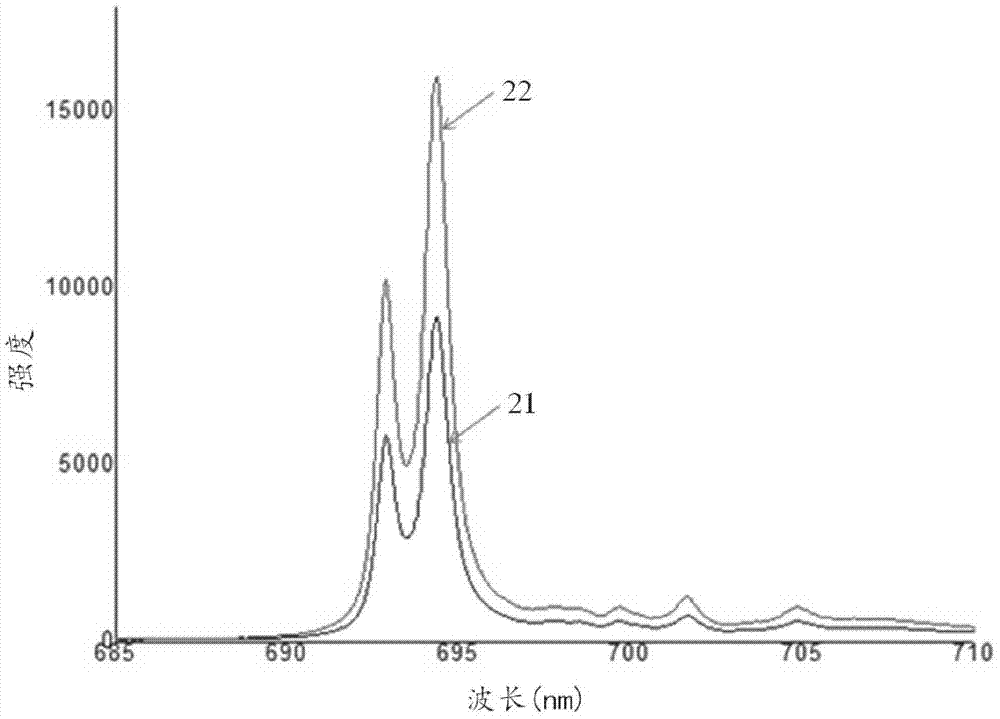

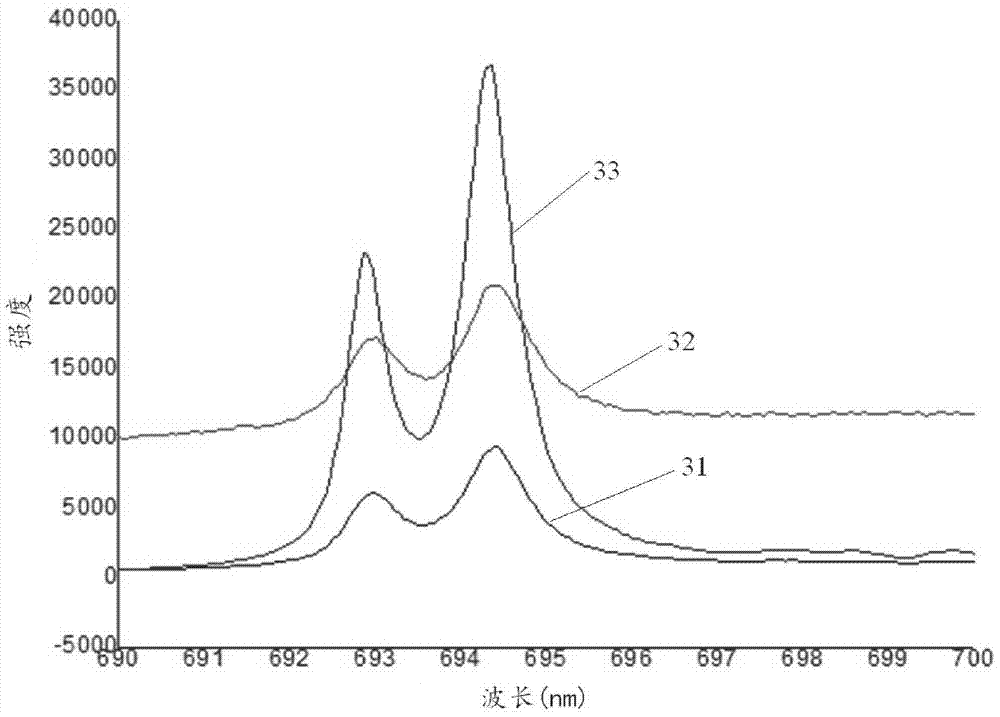

Particle beam image coating used for spallation neutron source and preparation method of particle beam image coating

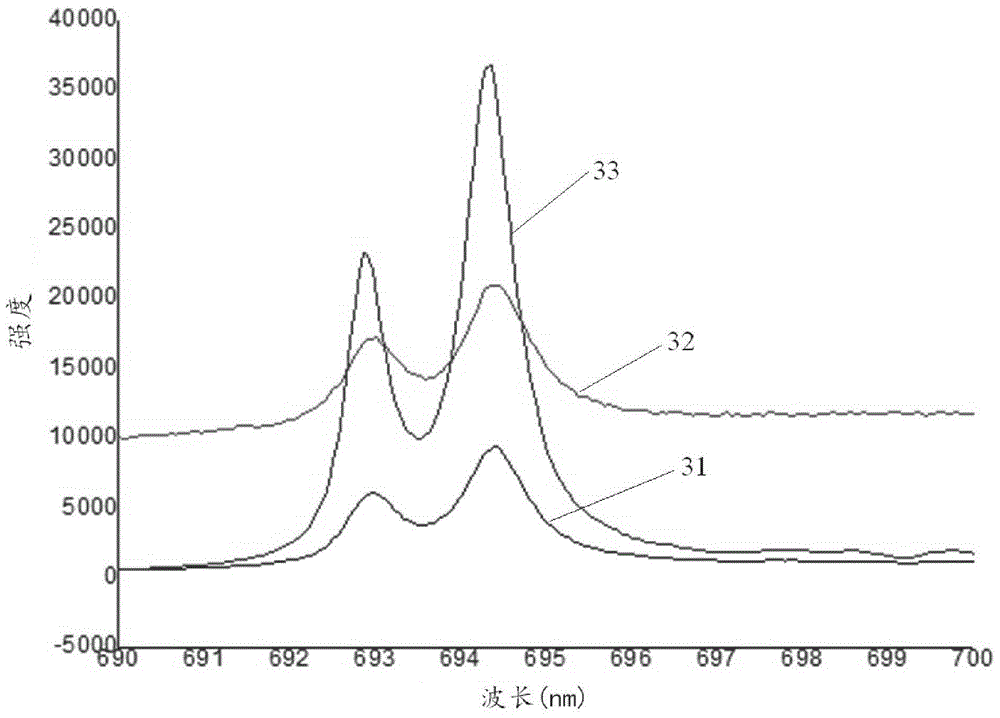

ActiveCN104793233AImprove luminous efficiencySatisfy the beam distributionX/gamma/cosmic radiation measurmentCurrent distributionParticle beam

The invention discloses a particle beam image coating used for a spallation neutron source and a preparation method of the particle beam image coating. The particle beam image coating is coated on the outer surface of a front window of a bombarded target, and the main active ingredient of the particle beam image coating is Cr3+doped Al2O3 powder. The preparation method includes coating the Cr3+doped Al2O3 powder on the outer surface of the front window of the target by means of low-power flame spraying to form the image coating. The image coating is developed specially for the spallation neutron source which is a second spallation neutron source using the image coating in the world after an American spallation neutron source is developed. The particle beam image coating is high in light emitting efficiency, using needs on accurately judging beam current distribution and strength at a target position during particle beam bombarding of high-energy proton beam current or ion beam current can be met, and a foundation is laid for further study and development of the spallation neutron source in China.

Owner:DONGGUAN NEUTRON SCI CENT +1

Wide-range miniaturized space proton detector and detection method

PendingCN112147668AAchieving intensive designLarge dynamic rangeX-ray spectral distribution measurementScintillation crystalsEngineering

The invention relates to the technical field of space radiation environment detection, and particularly relates to a wide-range miniaturized space proton detector and a detection method. The wide-range miniaturized space proton detector comprises a low-energy detection area and a high-energy detection area, wherein the low-energy detection area is used for detecting and identifying medium-energy protons and is provided with a graphene film, a microchannel plate and a first detector; the high-energy detection area is used for detecting and identifying high-energy protons and is provided with asecond detector, a Ta energy reduction sheet and a third detector; and the first detector, the second detector, the Ta energy reduction sheet and the third detector are sequentially arranged from thinto thick. According to the invention, the medium-energy protons in a low-energy section are detected and identified through a method of the graphene film and a silicon semiconductor, and the high-energy protons in a high-energy section are detected and identified through a telescope type detection method formed by the silicon semiconductor, the Ta energy reduction sheet and a scintillation crystal, so that the measurement range is large, the measurement range is wide, the size of the detector is reduced, the miniaturization design of the detector is realized, and the requirements of militarysatellite carrying and micro-nano satellites can be met.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

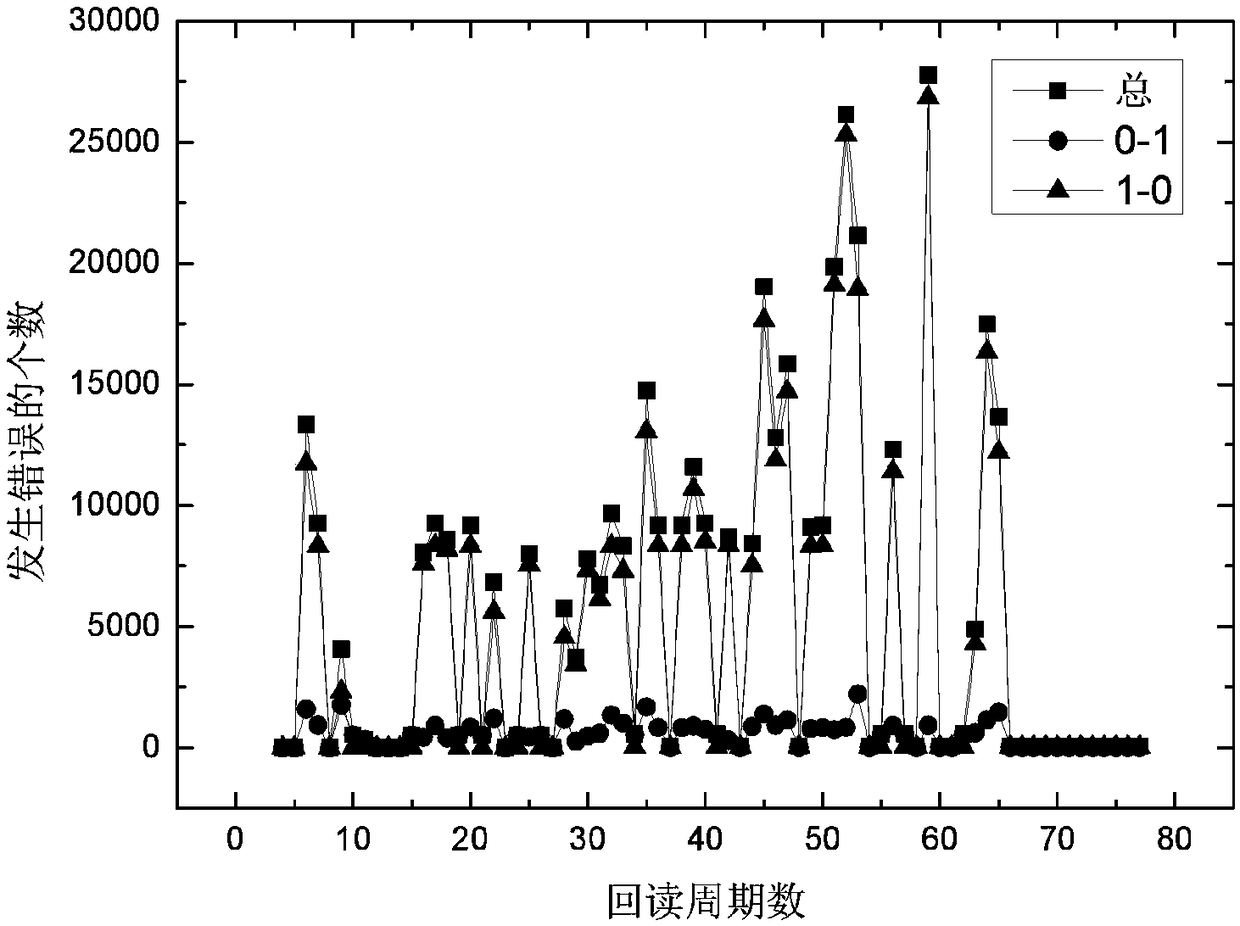

Test method for detecting single particle disturbance of memories by taking protons as radiation source

ActiveCN108597557ALET value decreasesEliminate the effects ofStatic storageHigh energy protonData extraction

The invention discloses a test method for detecting single particle disturbance of memories by taking protons as a radiation source. The method comprises the following steps of selecting memory samples; performing power-on total parameter testing on the selected memory samples to verify functions of the memory samples; selecting proton beams with certain energy and fluence rates on a medium and high-energy proton accelerator; connecting the memories and a circuit board well, and performing power-on testing again; filling all the memories with data; backwards reading the data from the memories,and turning on the proton beams meeting the requirements when a test system is stable, thereby performing irradiation on the single memory; and moving the subsequent memories to the beam output positions of the beams in sequence, and replacing the energy of the proton beams, until all energy points are tested. The single particle disturbance effect is detected by taking the protons as the radiation source; compared with other radiation sources, the protons are more reliable, simpler and more convenient; and the data extraction accuracy is ensured while the efficiency is improved.

Owner:XIANGTAN UNIV

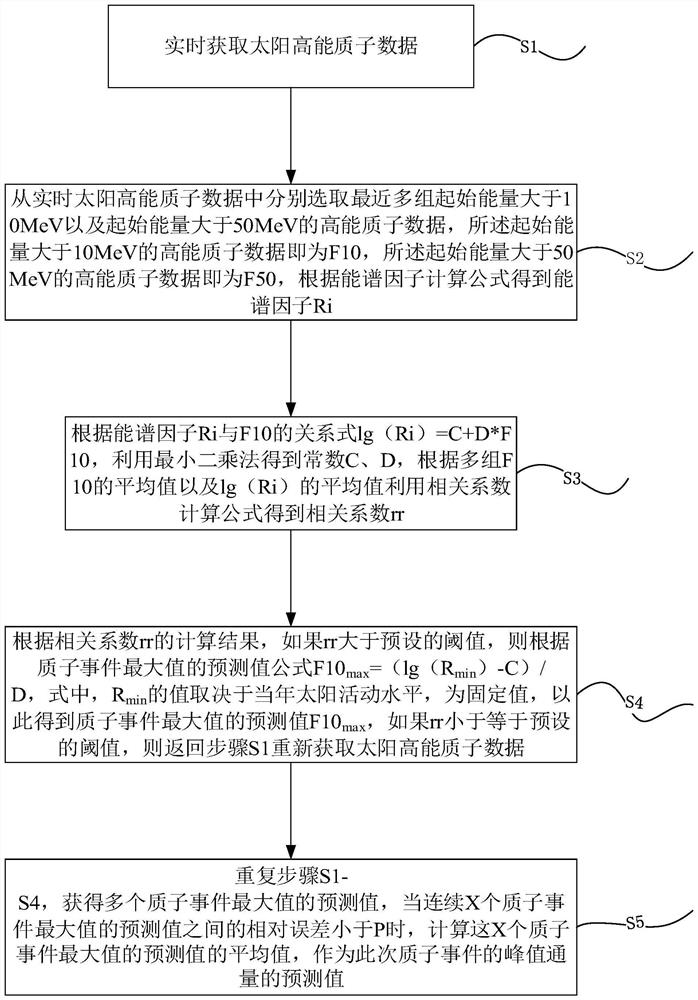

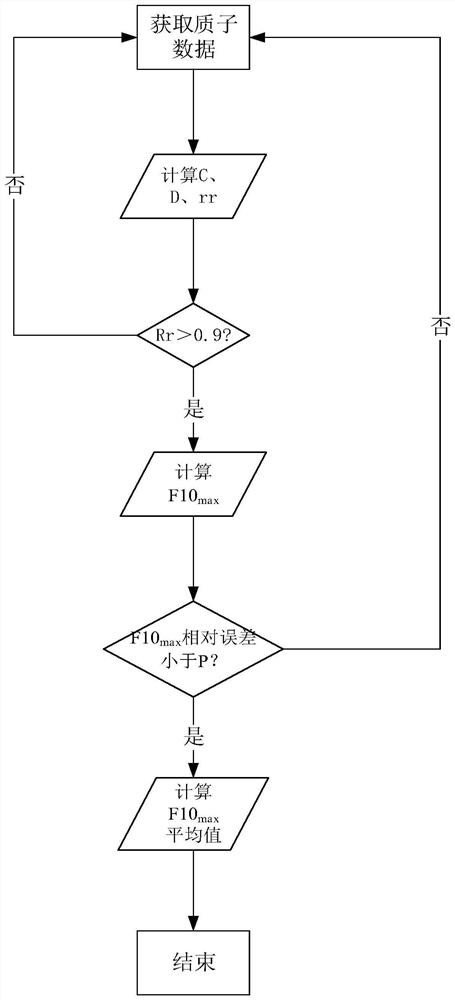

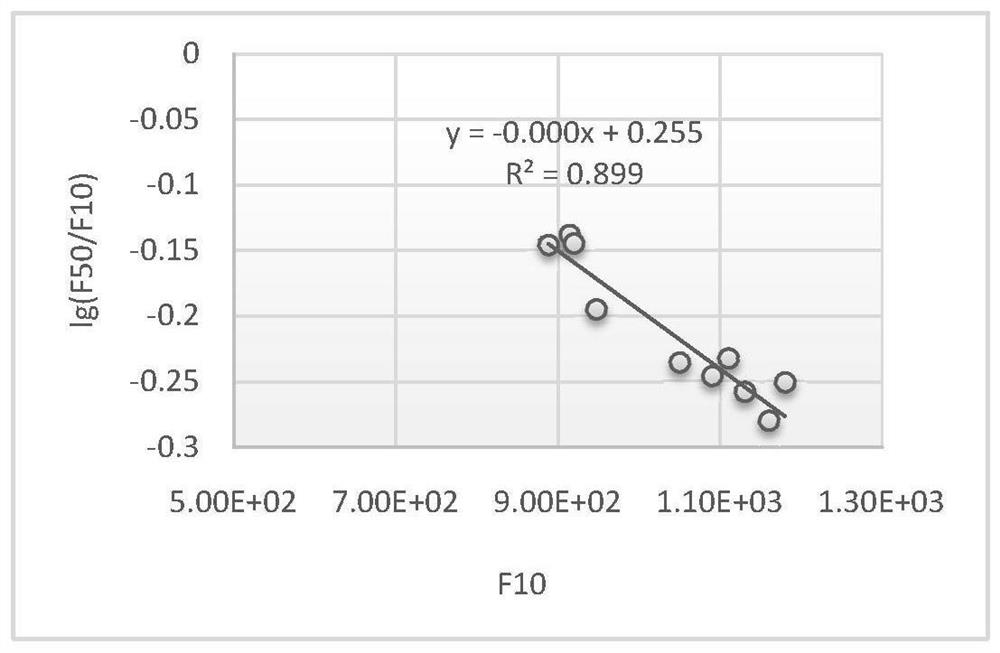

Solar proton event peak flux prediction method

ActiveCN114254544AEfficient determination of predicted values for peak fluxAvoid false positivesWeather condition predictionDesign optimisation/simulationCorrelation coefficientPredictive methods

The invention discloses a solar proton event peak flux prediction method, and relates to the technical field of proton events, and the method comprises the following steps: S1, obtaining solar high-energy proton data in real time; s2, obtaining an energy spectrum factor Ri according to an energy spectrum factor calculation formula; s3, according to a relational expression lg (Ri) = C + D * F10 of the energy spectrum factor Ri and F10, obtaining constants C and D by using a least square method, and meanwhile, obtaining a correlation coefficient rr according to a correlation coefficient calculation formula; s4, calculating a predicted value F10max of the maximum value of the proton event according to a predicted value formula F10max = (lg (Rmin)-C) / D of the maximum value of the proton event, S5, repeating the steps S1-S4 to obtain predicted values of the maximum values of a plurality of proton events, calculating an average value of the predicted values of the maximum values of X continuous proton events when a relative error between the predicted values of the maximum values of the X continuous proton events is smaller than P, and if the relative error between the predicted values of the maximum values of the X continuous proton events is smaller than P, calculating the average value of the predicted values of the maximum values of the X continuous proton events. Therefore, the prediction value of the peak flux of the proton event is calculated.

Owner:数字太空北京智能技术研究院有限公司

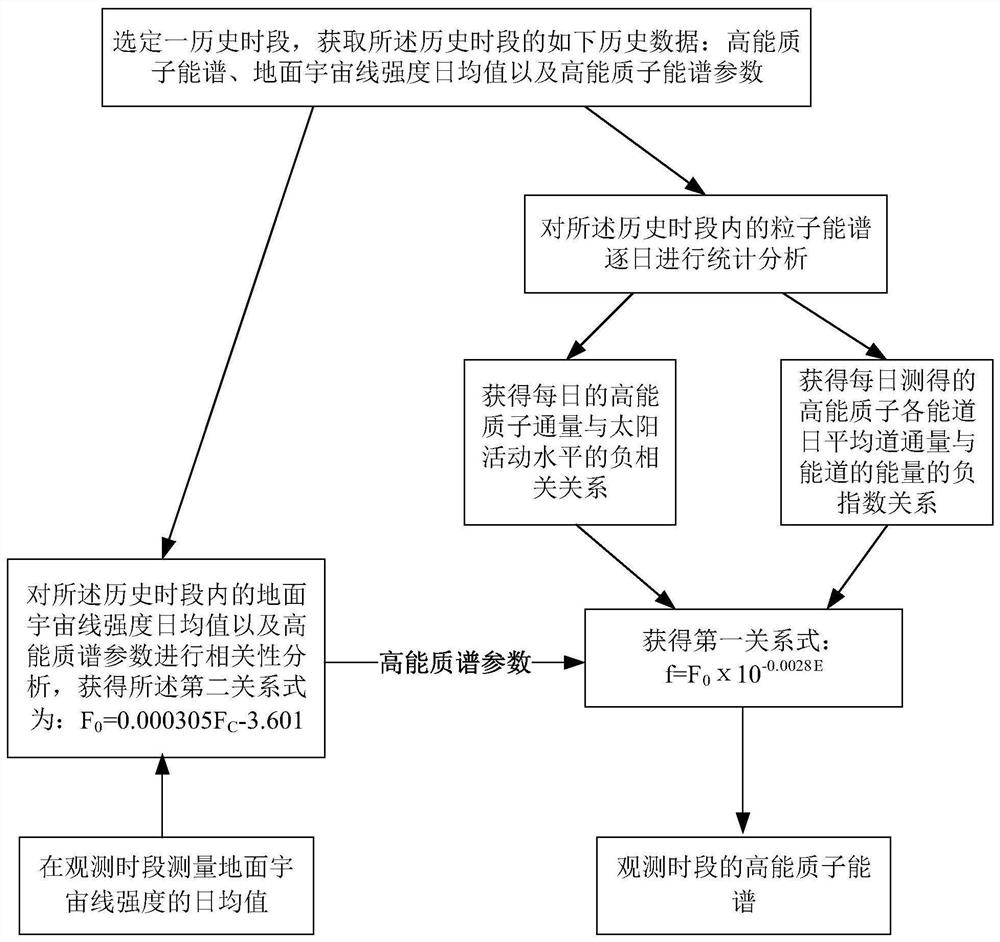

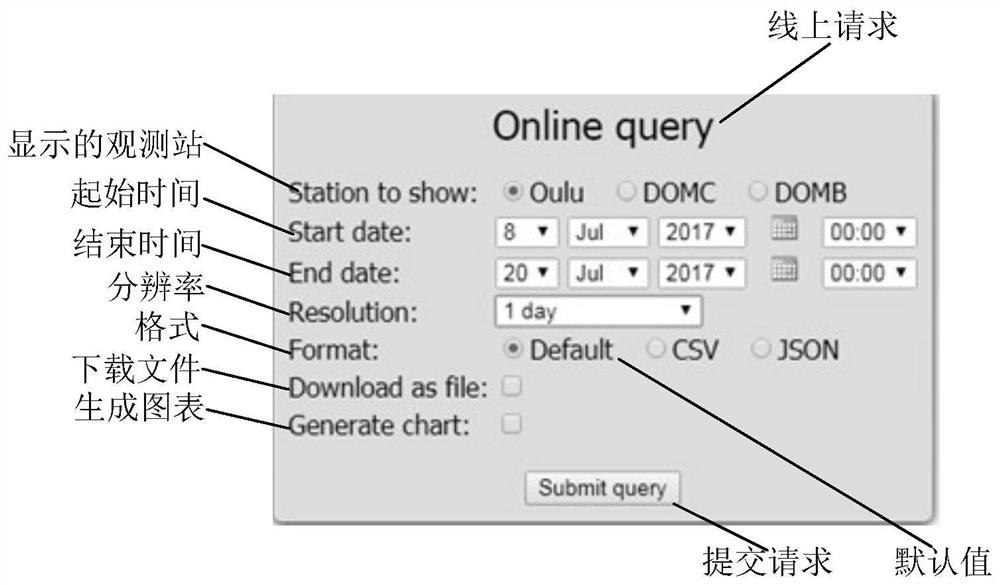

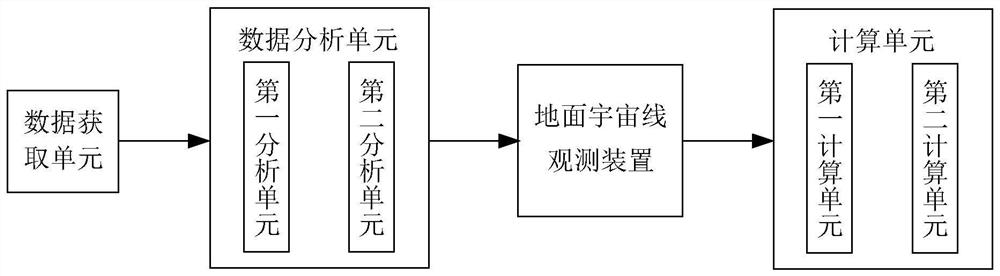

High-energy proton energy spectrum calculation method and calculation system

PendingCN113158533AImprove accuracySimple methodX-ray spectral distribution measurementDesign optimisation/simulationSpace environmentNuclear engineering

The invention provides a high-energy proton energy spectrum calculation method and system. The method comprises the following steps: selecting a historical time period, and acquiring the following historical data of the historical time period: a high-energy proton energy spectrum, a ground cosmic ray intensity daily mean value, and a high-energy proton energy spectrum parameter; analyzing the high-energy proton energy spectrum in the historical time period to obtain a first relational expression; analyzing the daily mean value of the ground cosmic ray intensity and the high-energy proton spectrum parameter in the historical period to obtain a second relational expression; measuring a daily mean value of the ground cosmic ray intensity in an observation period; and according to the daily mean value of the ground cosmic ray intensity measured in the observation time period, the first relational expression and the second relational expression, acquiring the high-energy proton energy spectrum in the observation time period. According to the method, the high-energy proton energy spectrum can be accurately calculated, external high-energy particle environment information is provided for a high-orbit satellite to accurately calculate the single-particle event probability, the radiation dose of a sensitive device and the like, targeted protection design is facilitated, and technical support is provided for satellite design and space environment guarantee of operation maintenance.

Owner:北京软奇科技有限公司

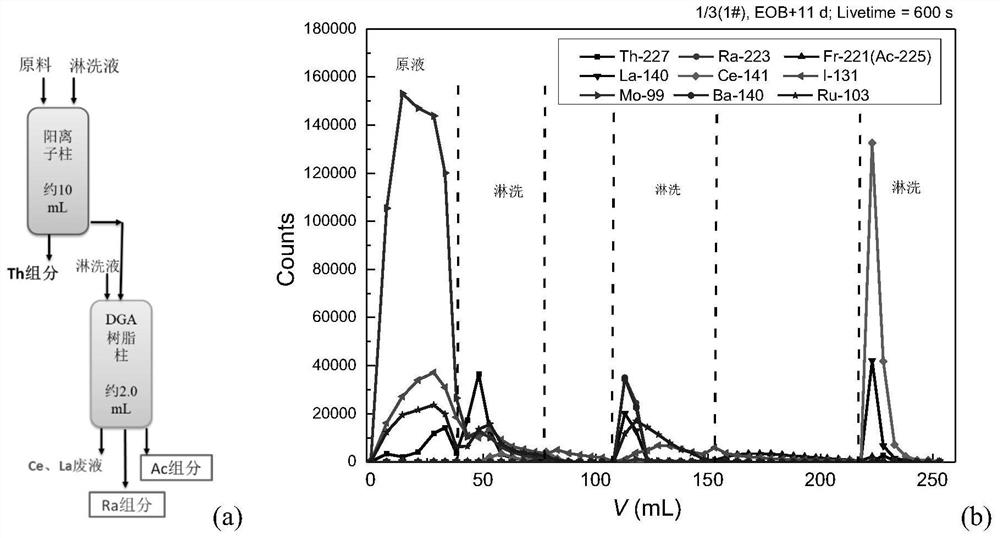

Method for separating and purifying 223Ra from spallation reaction caused by high-energy proton beam irradiation of < 232 > Th target

ActiveCN113066598ALow running costReduce material costsSpecific isotope recoveryIn-vivo radioactive preparationsNuclear chemistryFluorhydric Acid

The invention relates to a method for separating and purifying 223Ra from spallation reaction caused by high-energy proton beam irradiation of < 232 > Th target, which comprises the following steps of: 1) dissolving the irradiated metal Th target by adopting a method of heating sulfuric acid and hydrofluoric acid to replenish water to obtain a dissolved solution; 2) adopting a series system of a cationic resin column and a DGA resin column, adjusting the acid of the solution, injecting the solution into a cationic resin column, loading metal ions such as a target product Ra and a by-product Ac in the solution, and eluting with a complexing agent to remove matrix Th and a large number of fission daughters; (3) leaching Ra, Ac and other metal ions loaded on the cationic resin column by adopting inorganic acid, and enabling the obtained leaching solution containing Ra, Ac and other metal ions to directly pass through the DGA resin column to respectively obtain an Ra crude product and a byproduct Ac; and 4) leaching the Ra crude product through an ammonium citrate system to obtain a 223Ra product. The invention establishes a novel process which is simple, efficient and continuous in operation, can realize the aims of separating and purifying the localized 223Ra and recycling the 223Ra for multiple times, and has very important significance for positively meeting the requirements of medical research and application in China.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

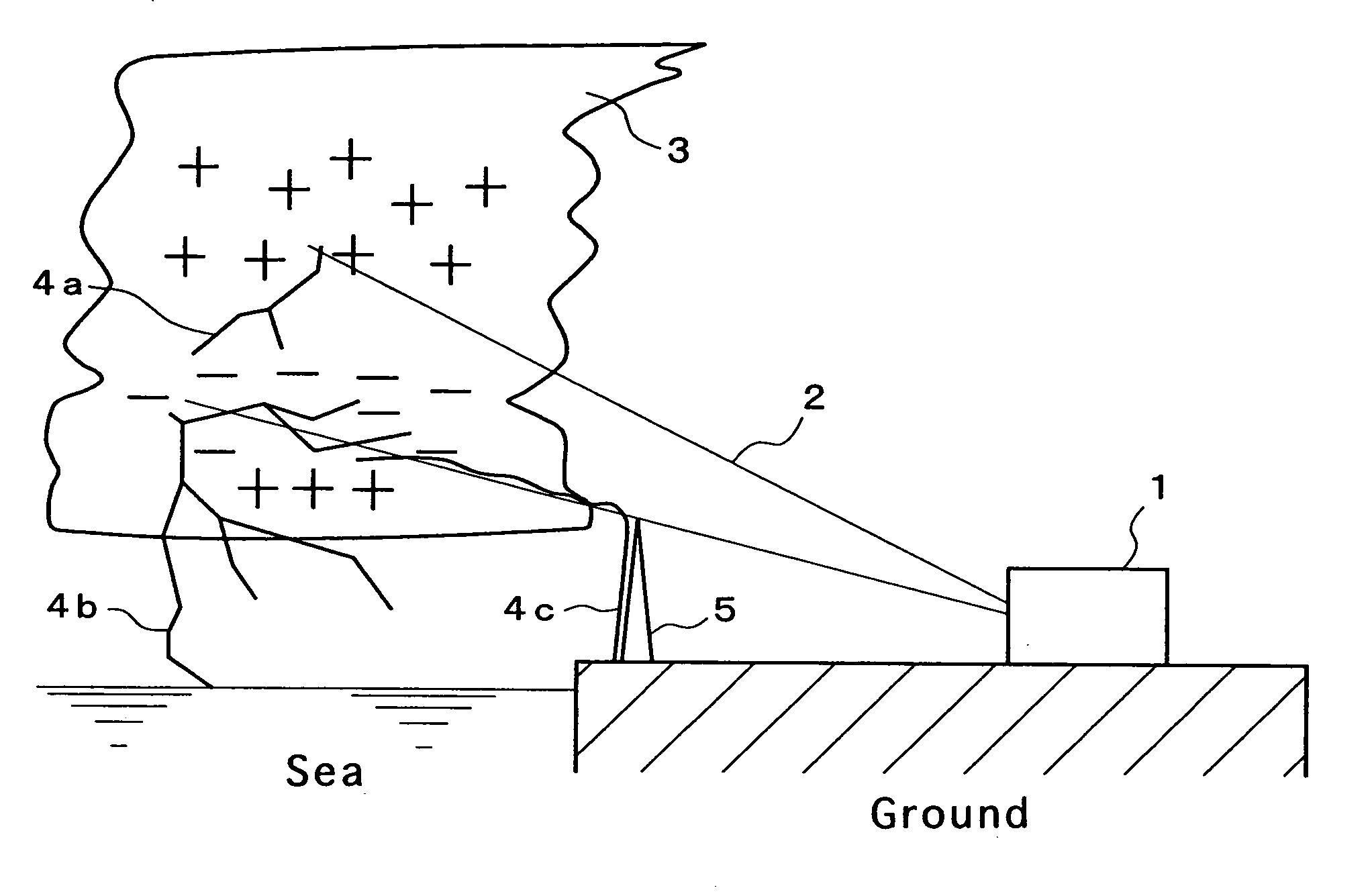

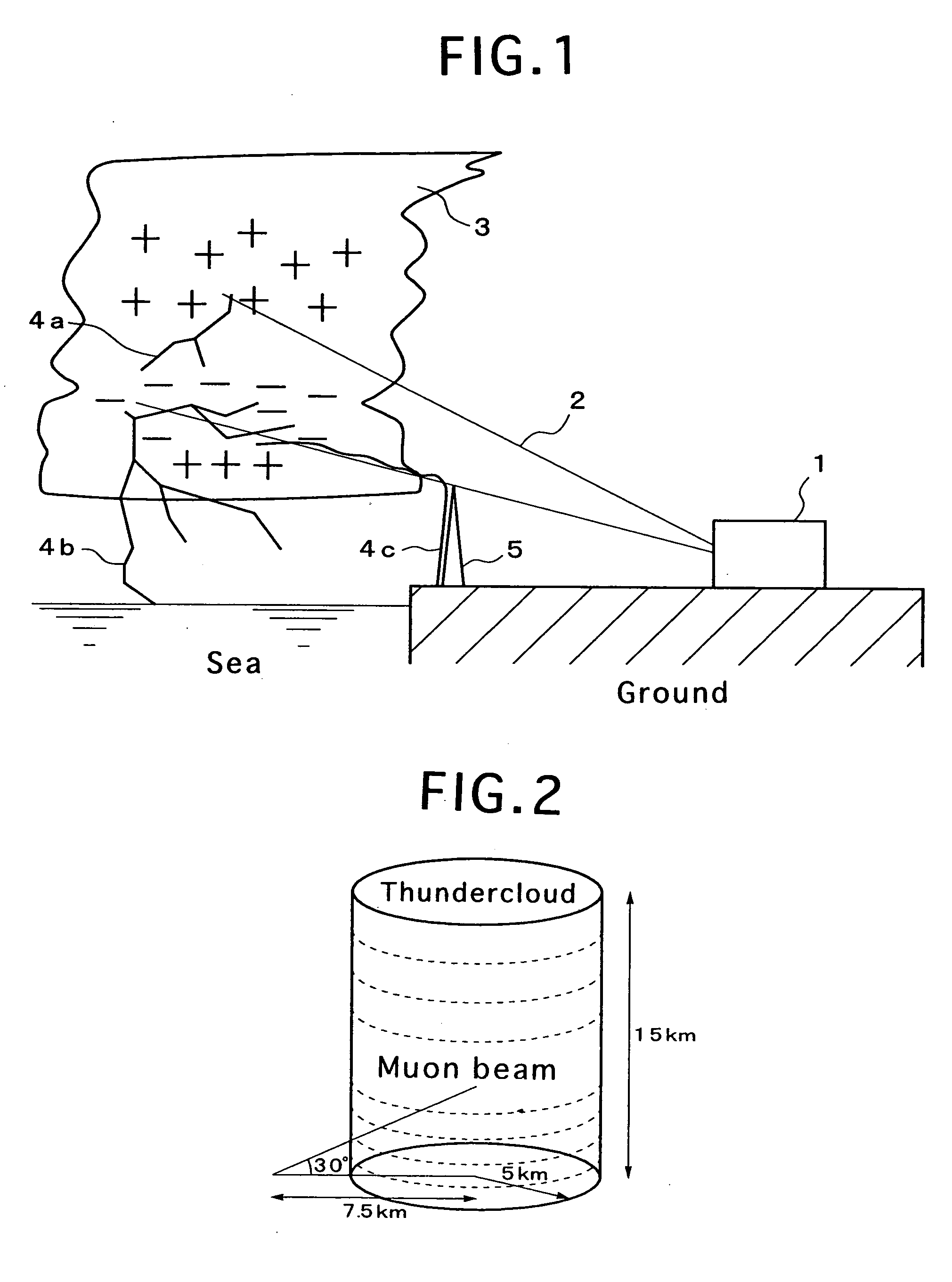

Method and apparatus for triggering of lightning discharge

InactiveUS20050195552A1Triggered more surelyImprove efficiencyEmergency protective arrangement detailsNuclear targetsIonizationElectron

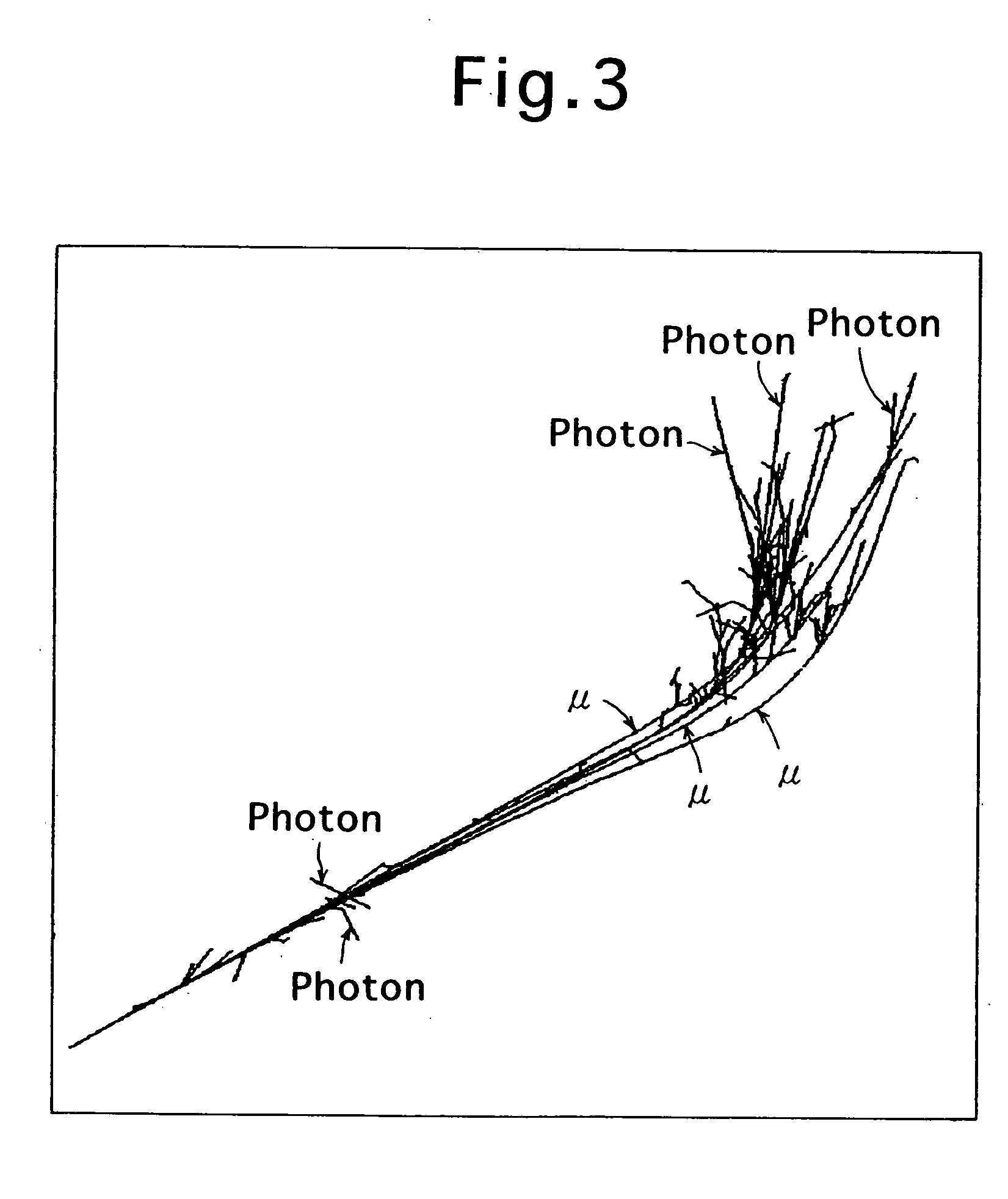

A method for triggering of lightning discharge which is high in lightning triggering efficiency and capable of surely triggering lightning discharge is provided. The method comprises collimating muons emitted from a high energy proton or electron accelerator, and irradiating the collimated muon beam toward a thundercloud to thereby promote ionization of air in the thundercloud and trigger lightning discharge. An apparatus for implementing the method for triggering of lightning is also provided. The apparatus comprises a high energy proton or electron accelerator from which a proton beam or an electron beam is emitted, a target from which pions are emitted by irradiating the target with the proton or electron beam, a collimator for collimating muons generated by the decay of the pions, and an accelerating tube for accelerating the collimated muon beam and irradiating the muon beam toward a thundercloud.

Owner:JAPAN NUCLEAR CYCLE DEV INST

Particle beam imaging coating for spallation neutron source and preparation method thereof

ActiveCN104793233BImprove luminous efficiencyX/gamma/cosmic radiation measurmentBeam sourceParticle beam

The invention discloses a particle beam image coating used for a spallation neutron source and a preparation method of the particle beam image coating. The particle beam image coating is coated on the outer surface of a front window of a bombarded target, and the main active ingredient of the particle beam image coating is Cr3+doped Al2O3 powder. The preparation method includes coating the Cr3+doped Al2O3 powder on the outer surface of the front window of the target by means of low-power flame spraying to form the image coating. The image coating is developed specially for the spallation neutron source which is a second spallation neutron source using the image coating in the world after an American spallation neutron source is developed. The particle beam image coating is high in light emitting efficiency, using needs on accurately judging beam current distribution and strength at a target position during particle beam bombarding of high-energy proton beam current or ion beam current can be met, and a foundation is laid for further study and development of the spallation neutron source in China.

Owner:DONGGUAN NEUTRON SCI CENT +1

Satellite-borne medium-energy proton detector

ActiveCN111948698AEfficient exclusionAchieve interferenceX-ray spectral distribution measurementNuclear engineeringSolar particle event

The invention discloses a medium-energy proton detector, which comprises a probe and an electronics part, and is characterized in that the probe is used for outputting charge pulses of medium-energy protons to the electronics part; wherein the detection energy range of the medium-energy protons is 20 KeV to 5 MeV; and the electronics part is used for processing the received charge pulse and obtaining the energy of the medium-energy protons by analyzing the amplitude of the pulse signal. According to the detector, the detection range of the medium-energy protons can be as low as 20 KeV, the medium-energy protons are connected up to the detection energy sections of the high-energy protons and partially coincide down with the detection energy sections of the plasmas, so that all-energy-spectrum seamless measurement, fine energy spectrum measurement and high-direction resolution measurement can be achieved, and therefore energy transmission and distribution state changes of space particlesare monitored. The detector is of great significance to research of magnetic tail ground energy transportation and global radiation environment modeling, and can perform early warning on solar protonevents.

Owner:NAT SPACE SCI CENT CAS

Process for producing polymer materials

This invention relates to the radiation chemistry and high-energy chemistry technologies for the production, by heat-and-radiation treatment of workpieces, of enhanced-performance polymer materials, in particular, of polytetrafluoroethylene (PTFE) and other sorts of fluoroplastics used in various industries. Specifically, it relates to treating workpieces by high-energy ionizing radiation at a temperature strictly higher than the polymer crystalline phase melting point in an anoxic environment. The treatment is done via a pulsed linear electron accelerator generating ionizing radiation until an absorbed dose of 0-500 kGy is achieved. During the irradiation process, the polymer temperature is reduced by not more than 0.5° C. / 10 kGy, and subsequent to the ionizing radiation treatment, the polymer is heat treated. Alpha radiation, gamma radiation, electron radiation, irradiation with high-energy protons and neutrons, radiation from natural sources are used for the treatment. By this treatment method, physical and mechanical properties of the material are improved and consistency and programmability of the physical and mechanical characteristics are provided. 7 sub-claims.

Owner:LLC QUANTUM R

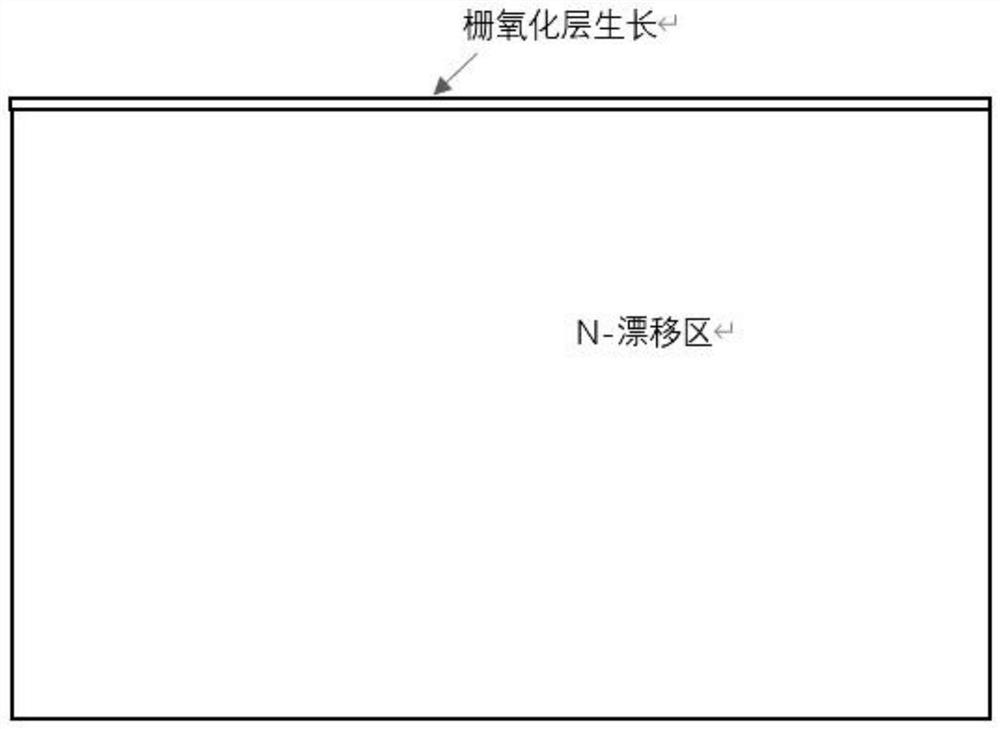

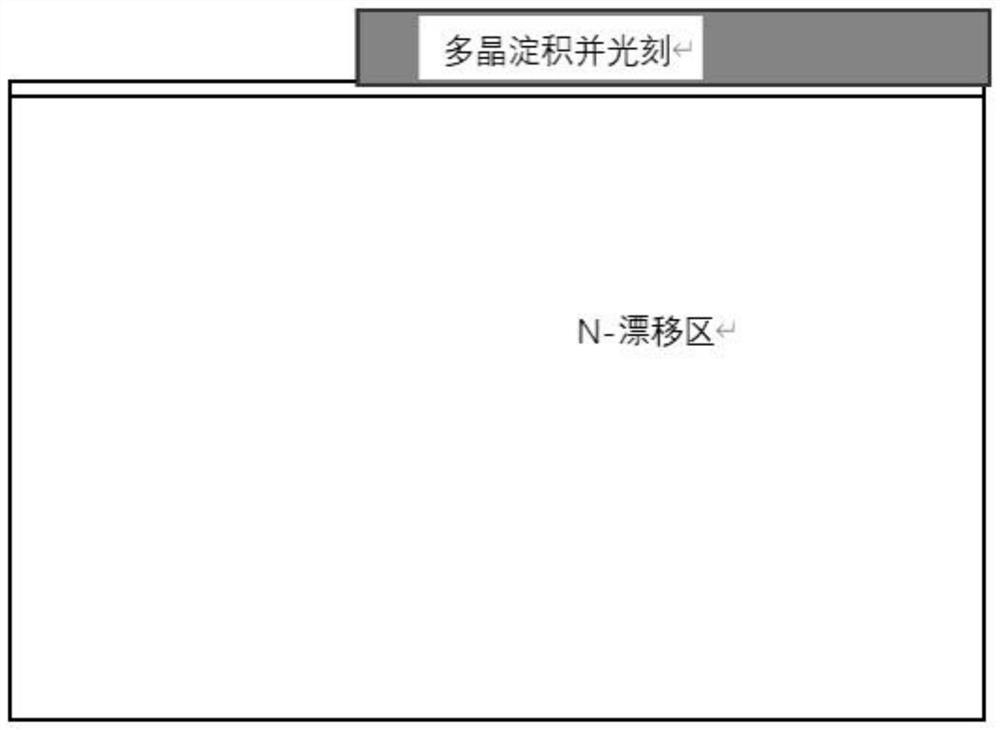

Method for forming IGBT electric field stop layer

PendingCN114429904AWon't oscillateTransistorSemiconductor/solid-state device manufacturingSputteringGate oxide

The invention provides a method for forming an IGBT electric field stop layer, and relates to the technical field of IGBT processes. The method for forming the IGBT electric field stop layer comprises the following steps: S1, preparing a substrate; s2, growing a gate oxide layer; s3, polycrystal deposition and photoetching are carried out; s4, injecting a P-type body region; s5, propelling a P-type body region; s6, performing N + injection and propulsion; s7, depositing a dielectric layer; s8, performing contact hole photoetching and metal sputtering; s9, injecting a P-type collector region on the back surface; s10, annealing a collector region on the back surface; s11, high-energy protons are injected into the back surface for many times; s12, performing high-energy proton injection annealing; and S13, back collector electrode metal sputtering is carried out. According to the method, high-energy proton injection is carried out for many times, then annealing is carried out at the temperature of 350-450 DEG C and under the N2 condition, N-type impurity distribution with the thickness of 20-50 microns is formed on the back face of the IGBT, and therefore the function of an electric field stop layer is achieved, due to the fact that the number of electrons in the thick electric field stop layer is large, the current cannot suddenly drop to zero when the IGBT is turned off, and oscillation of the IGBT cannot be caused.

Owner:权芯微电子科技无锡有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com