Method for separating and purifying 223Ra from spallation reaction caused by high-energy proton beam irradiation of < 232 > Th target

A high-energy proton and irradiation technology, applied in the fields of reactor/accelerator external conversion, radiation-converting chemical element devices, pharmaceutical formulations, etc. problems such as low separation efficiency, to avoid product loss, reduce material costs, and reduce radiation doses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

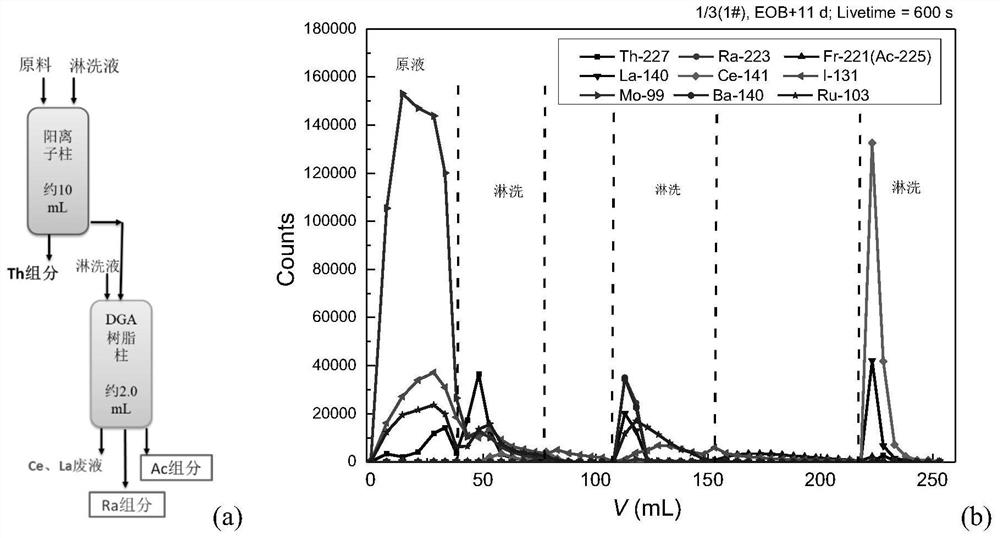

[0083] This example is used to illustrate the dissolution of metal thorium target, and the removal of matrix Th by two-column separation system after directly adjusting the acidity, and the target product 223 Ra and by-products 225 Feasibility of Ac separation.

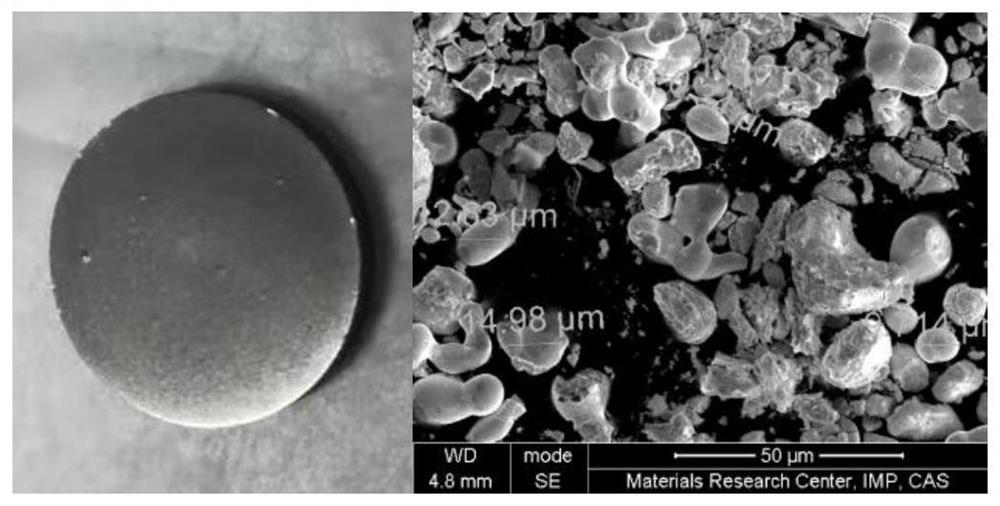

[0084] The Th targets used in the present invention are metal Th powders provided by the Changchun Institute of Applied Chemistry, Chinese Academy of Sciences. They are pressed by a liquid tablet press at a pressure range of 13 MPa, with a diameter of 15 mm and a thickness of 2 to 4 mm. Photo and SEM image reference figure 1 .

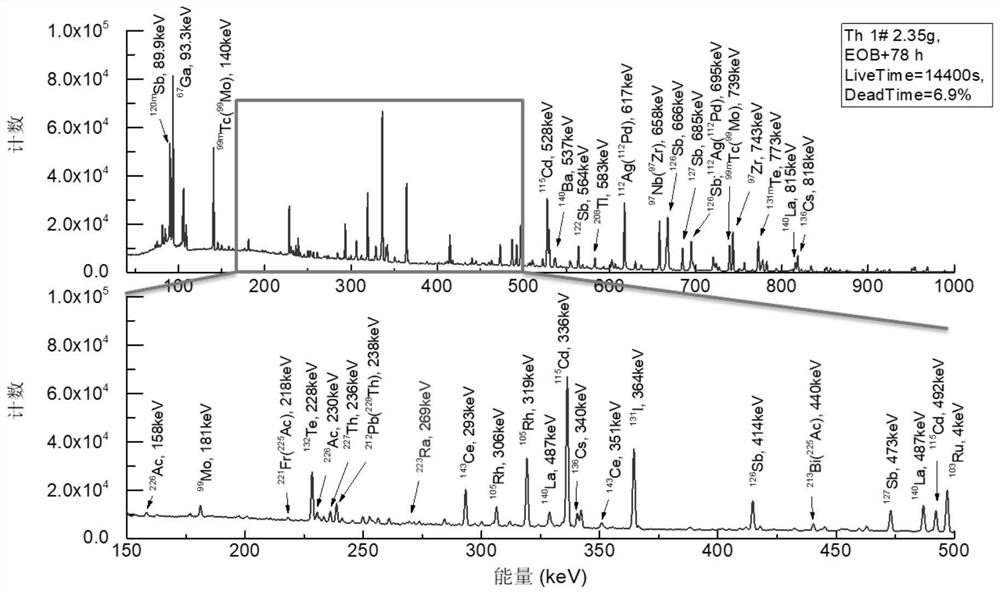

[0085] Using the accelerator HIRFL of the Institute of Modern Physics, Chinese Academy of Sciences (Lanzhou), the energy is 100MeV, and the proton beam with an average current intensity of 24nA is used to irradiate No. 1 metal Th target (2.35g), and the irradiation time is 7 hours. The Th target is irradiated. The shape before and after remains the same. from figure 2 It can be seen from...

Embodiment 2

[0096] This example is used to illustrate the purification from the isolated Ra component crude product 223 Feasibility of Ra products.

[0097] Gained according to Example 1 223 The γ energy spectrum of Ra crude product components ( Figure 4 ), confirming that the removal of the 140 Ba impurity, to meet the product purity of clinical application and research of nuclear medicine. The present embodiment partly refers to the ammonium citrate complexing agent described in "Separation of Radium and Barium by Ion Exchange Method", Mao Jiajun, Atomic Energy Science and Technology, Volume 08, 1963, pages 635-637. Also, a cationic resin column and a branched DGA resin column were used in series, and the volumes of the two columns (column 3 and column 4) were 10 mL and 2 mL, respectively.

[0098] With the obtained part in embodiment 1 223 Ra crude product purification treatment, control the flow rate to 2.0mL / min, the specific washing steps are:

[0099] (a) will contain 5M nit...

Embodiment 3

[0105] This embodiment is used to illustrate recovering from the Th component solution after separation 223 Feasibility of Ra to build a simple 227 Th / 223 Ra generator.

[0106] 227 Th decays to 223Ra, and the time for the activity of the latter to reach the peak is 20.8 days. Based on the calculation results, the inventor suggested that a recovery operation can be performed 10-18 days after the Th component is separated. Then, according to whether the recovered dose meets the needs of subsequent research and application, the purified Th component is further recycled and recycled. 223 Ra products, a total of 6 to 10 times (10 to 18 days / time), so as to provide hospitals or research institutes with a higher single-day average dose 223 Ra drug.

[0107] The series system of cationic resin column and branched DGA resin column in Example 1 is also adopted, and the volumes of column 1 and column 2 are respectively 5 mL and 2 mL. On the 14th day after the Th component was s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com