Particle beam imaging coating for spallation neutron source and preparation method thereof

A spallation neutron source and image coating technology, applied in radiation measurement, measurement devices, instruments, etc., can solve the problems of limited research reports and unpublished, and achieve the effect of high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

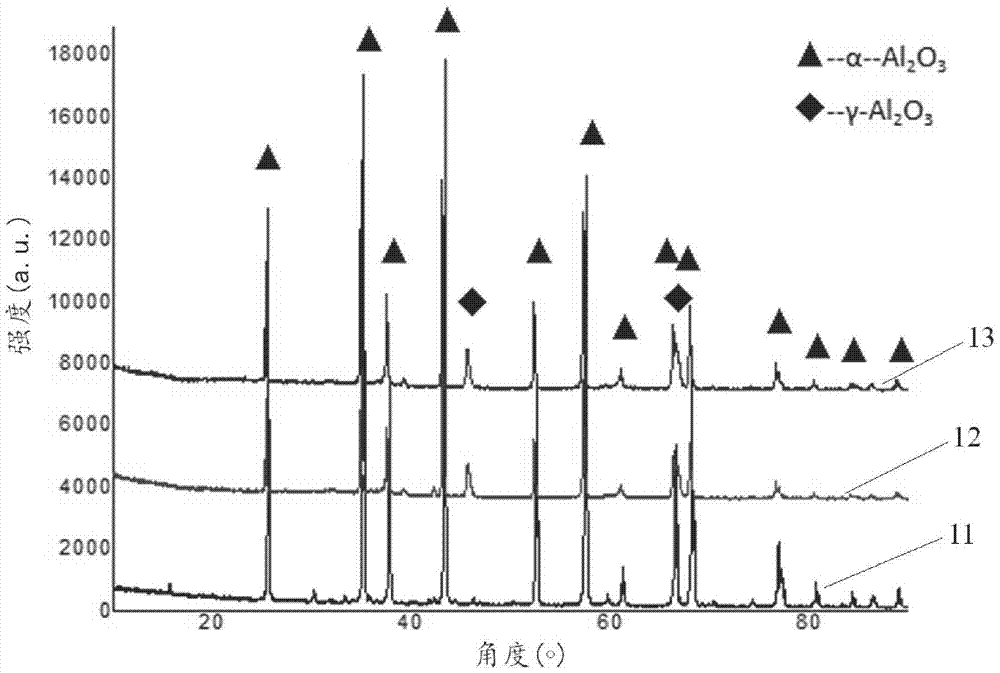

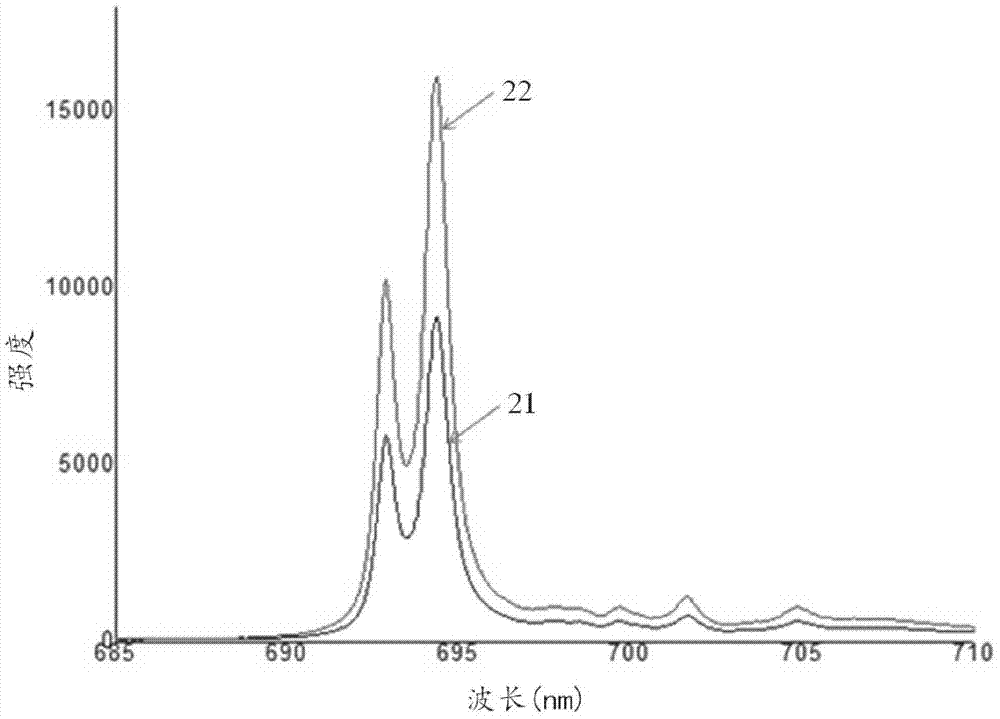

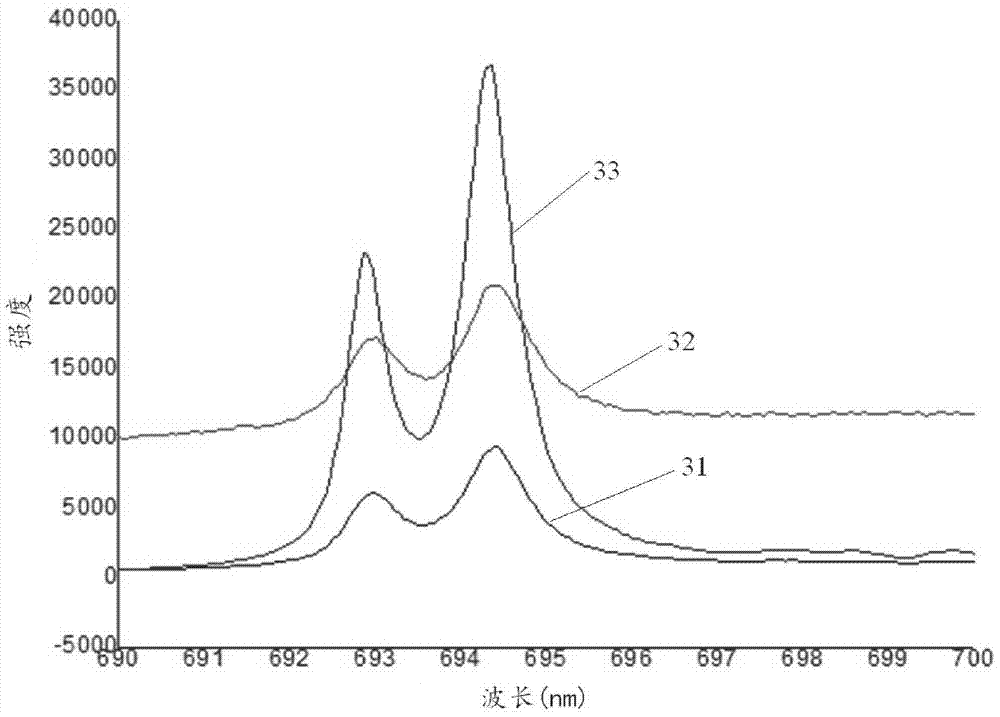

[0029] In this example, Al(NO 3 ) 3 9H 2 O, Cr(NO 3 ) 3 9H 2 O was used as raw material, and Cr was prepared by chemical synthesis 3+ :Al 2 o 3 Powder, as follows:

[0030] Al(NO 3 ) 3 9H 2 O and Cr(NO 3 ) 3 9H 2 O is placed in the nitrate solution to make it fully dissolve, and the pH value of the nitrate solution is about 4; Citric acid: (Al 3+ +Cr 3+ ) substance mass ratio is about 10, the titration is completed, and the resulting sol is the precursor; the precipitate is washed repeatedly with alcohol, and after the alcohol washing is completed, the precursor is dried at 60-80 degrees, and then calcined at 1220 degrees to obtain Cr 3 + :Al 2 o 3 Powder. control Al(NO 3 ) 3 9H 2 O and Cr(NO 3 ) 3 9H 2 The amount of O is such that the prepared Cr 3+ :Al 2 o 3 In powder, Cr 3+ The doping amount is 1.5% of the total weight. In order to make the prepared powder suitable for spraying, the calcined Cr 3+ :Al 2 o 3 The powder is prepared into a sph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com