Control method and device for LED and semiconductor laser chip silicon wafer conveying device

The technology of a conveying device and a control method, which is applied in the field of silicon wafer conveying devices, can solve problems such as complex structure of sorting equipment, difficult chip sorting, and small chip size, so as to promote the technical level and mass production capacity, and improve the technical level and mass production capacity, the effect of compact and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

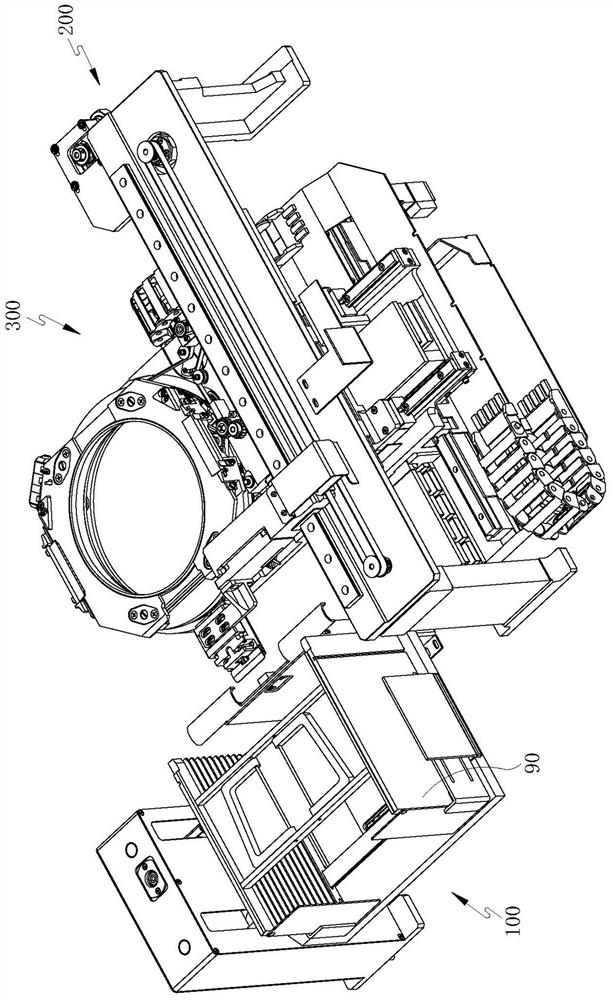

[0037] Such as figure 1 As shown, a method for controlling a silicon wafer delivery device for LED and semiconductor laser chips, including the initial step, the control step of the lifting table, the step of sending out silicon wafers and the step of retrieving empty silicon wafers, can quickly complete the sorting machine for LED and semiconductor laser chips silicon wafer delivery task.

[0038] Initial steps:

[0039] Such as figure 1 As shown, the silicon wafer box 90 loaded with silicon wafers is manually placed on the lifting platform 100. No silicon wafer is placed in the silicon wafer box 90 shown in the figure. The silicon wafer is a disc-shaped structure, and the disc film carries There are LED or semiconductor laser chips to be sorted, and then the equipment is powered on, and all components are in the initial position.

[0040] Lift control steps:

[0041] Such as figure 1 , image 3 , Figure 4 with Figure 5 Commonly shown, when the wafer cassette 90 is ...

Embodiment 2

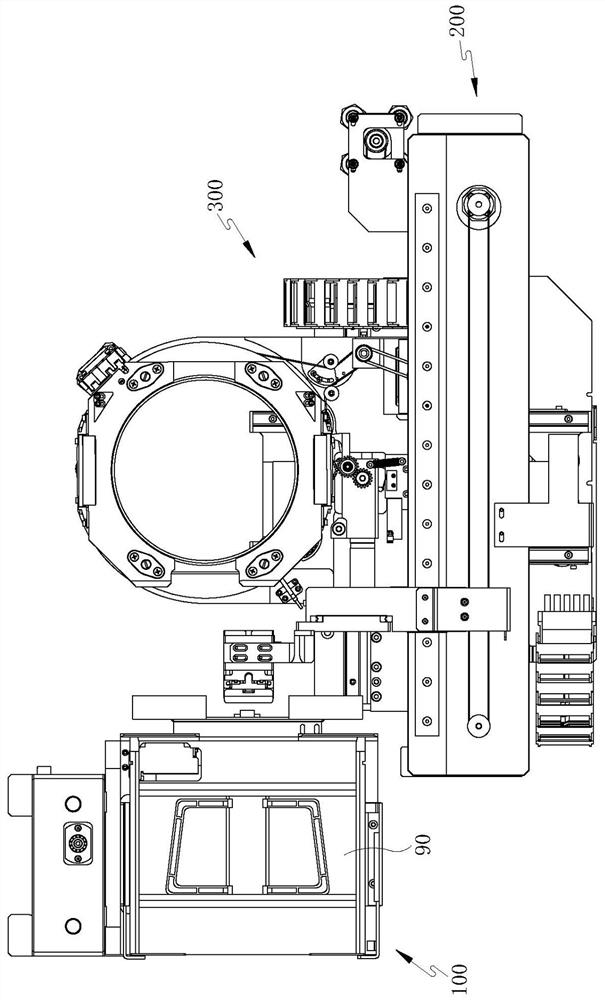

[0068] Such as figure 1 with figure 2 Commonly shown, an LED and semiconductor laser chip silicon wafer conveying device for realizing the control method of the LED and semiconductor laser chip silicon wafer conveying device described in Embodiment 1 includes a lifting platform 100 , a silicon wafer workbench 300 and a manipulator 200 .

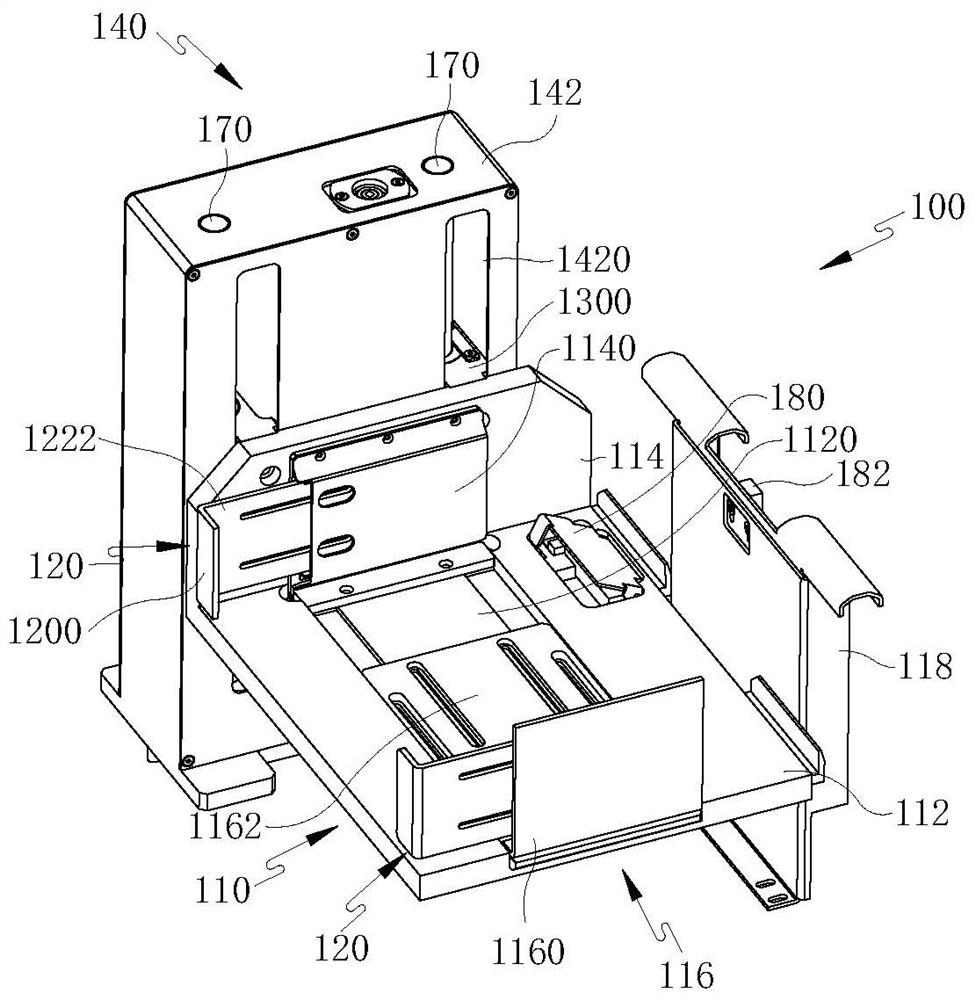

[0069] Such as figure 1 with image 3 As shown together, the lifting platform 100 includes a bracket 110 and a power box 140 for driving the bracket 110 up and down, and silicon wafers loaded with chips to be sorted are placed on the bracket 110 through the wafer cassette 90 .

[0070] Such as image 3 As shown, the bracket 110 includes a bottom plate 112 , a first side plate 114 and a second side plate 116 are vertically provided on the left and right sides of the bottom plate 112 , and a fourth side plate 118 is vertically provided on the front side. The opposite sides of the first side plate 114 and the second side plate 116 are fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com