Dial plate cleaning method

A dial and cleaning technology, applied in cleaning methods and utensils, cleaning methods using tools, cleaning flexible objects, etc., can solve problems such as non-environmental protection, low efficiency, and inability to guarantee quality, so as to improve work efficiency, ensure stability, The effect of preventing falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

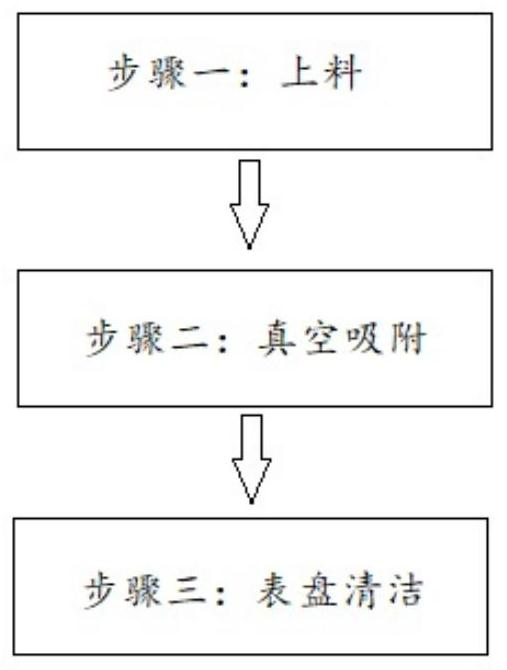

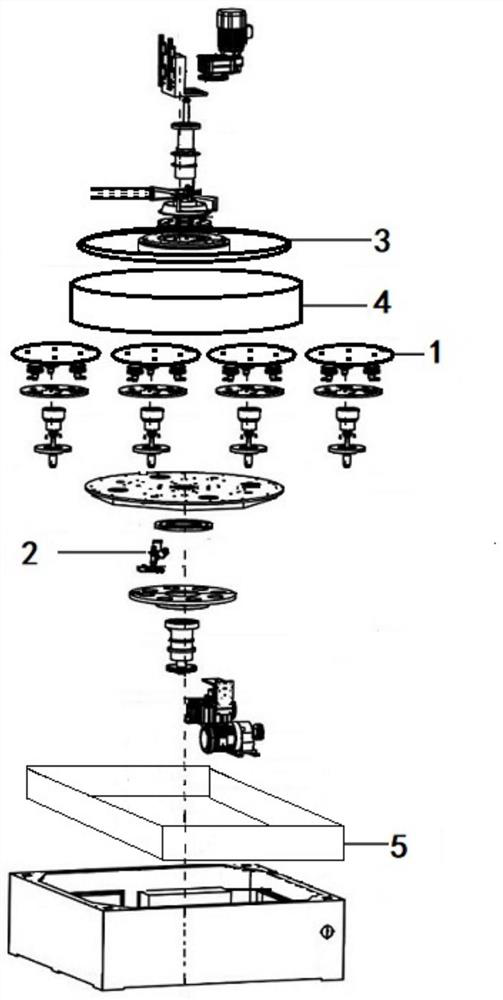

[0029] As shown in Figure 1-3, the dial cleaning method includes the following steps:

[0030] Step 1: Loading, placing the dial to be cleaned on the dial mold 1;

[0031] Step 2: Vacuum adsorption, the dial on the dial mold is firmly adsorbed by the vacuum adsorption component 2 to prevent it from falling during the cleaning process;

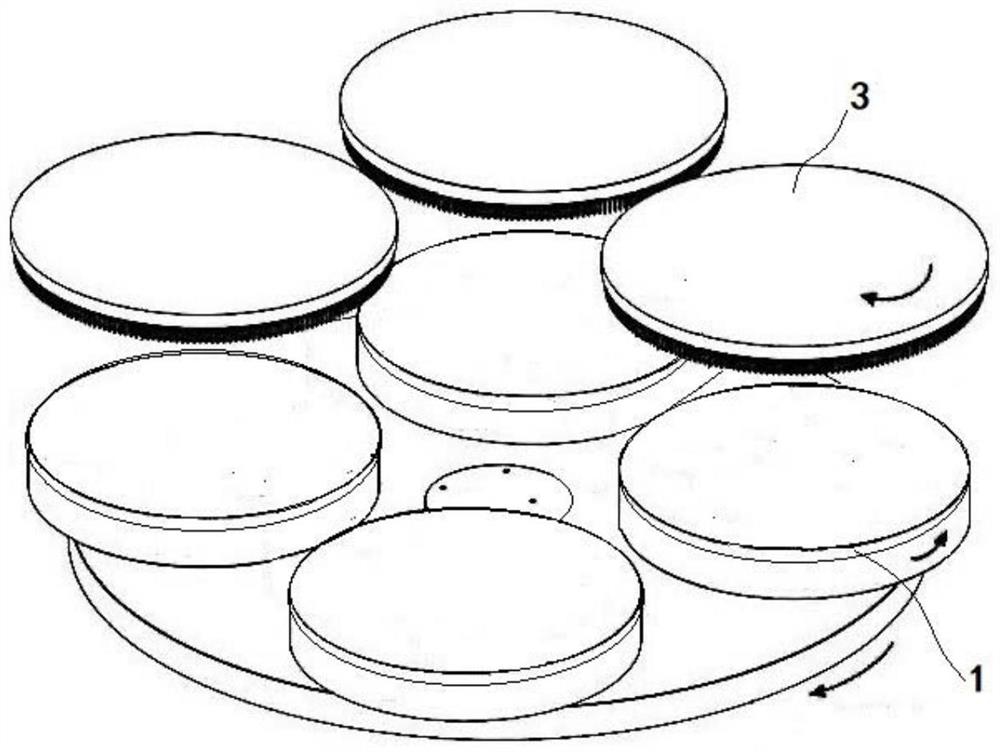

[0032] Step 3: Dial cleaning, using a soft wiping disc assembly 3 to wipe and clean the dial on the dial mold. The soft material used for wiping the disc assembly 3 is sponge, silk floss, felt, foam or silica gel. In this embodiment, the wiping disc assembly 3 is made of felt, of course, it can also be made of other soft materials, which have a certain degree of softness and elasticity, and can play the role of wiping.

[0033] Specifically, in step three, during the process of wiping and cleaning the dial on the dial mold 1 by the wiping disk assembly 3, the wiping disk assembly 3 keeps positive or negative rotation to wipe the dial on the d...

Embodiment 2

[0043] As shown in Figure 1-3, the dial cleaning method includes the following steps:

[0044] Step 1: Loading, placing the dial to be cleaned on the dial mold 1;

[0045] Step 2: Vacuum adsorption, the dial on the dial mold is firmly adsorbed by the vacuum adsorption component 2 to prevent it from falling during the cleaning process;

[0046] Step 3: Dial cleaning, using a soft wiping disc assembly 3 to wipe and clean the dial on the dial mold. The soft material used for wiping the disc assembly 3 is sponge, silk floss, felt, foam or silica gel. In this embodiment, the wiping disc assembly 3 is made of sponge, of course, it can also be made of other soft materials, which have a certain degree of softness and elasticity, and can play the role of wiping.

[0047] Specifically, in step three, during the process of wiping and cleaning the dial on the dial mold 1 by the wiping disk assembly 3, the wiping disk assembly 3 keeps positive or negative rotation to wipe the dial on the...

Embodiment 3

[0057] As shown in Figure 1-3, the dial cleaning method includes the following steps:

[0058] Step 1: Loading, placing the dial to be cleaned on the dial mold 1;

[0059] Step 2: Vacuum adsorption, the dial on the dial mold is firmly adsorbed by the vacuum adsorption component 2 to prevent it from falling during the cleaning process;

[0060] Step 3: Dial cleaning, using a soft wiping disc assembly 3 to wipe and clean the dial on the dial mold. The soft material used for wiping the disc assembly 3 is sponge, silk floss, felt, foam or silica gel. In this embodiment, the wiping plate assembly 3 is made of silica gel, of course, it can also be made of other soft materials, which have a certain degree of softness and elasticity, and can play the role of wiping.

[0061] Specifically, in step three, during the process of wiping and cleaning the dial on the dial mold 1 by the wiping disk assembly 3, the wiping disk assembly 3 keeps positive or negative rotation to wipe the dial o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com