Press abnormality detection system

A technology of abnormal detection and abnormal signal, which is applied in the field of stamping, can solve problems such as abnormal product batches and interrupted production, and achieve the effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

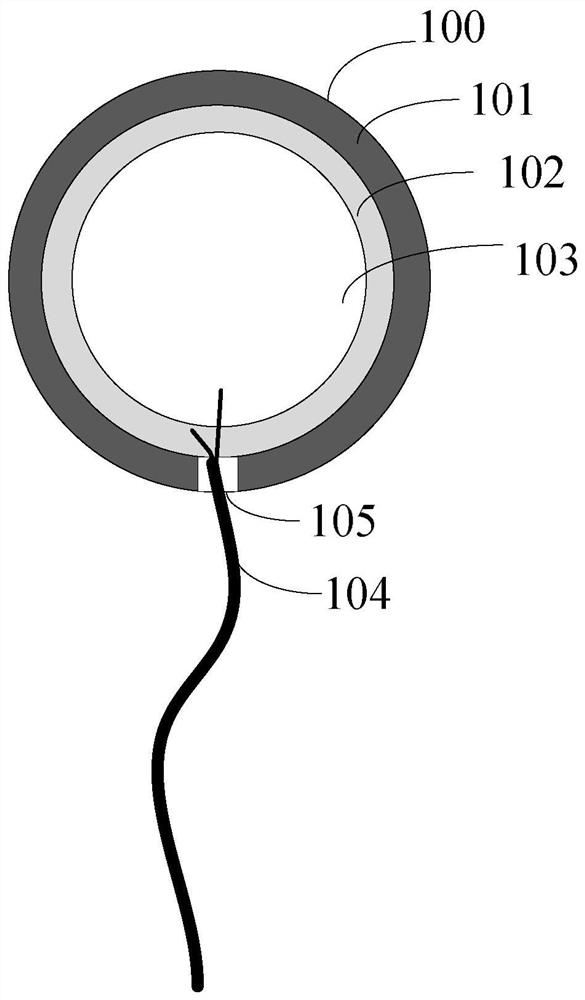

[0041] see figure 1 as shown, figure 1 It is a schematic structural diagram of an embodiment of the ultrasonic sensor 10 of the present invention. In this embodiment, the ultrasonic sensor 10 includes a housing 100 , a cover 101 , a copper foil 102 , a piezoelectric chip 103 and a cable 104 . The ultrasonic sensor 10 is installed on the test equipment for detecting the vibration signal of the test equipment and converting the vibration signal into a voltage response signal.

[0042] In this embodiment, one end of the housing 100 is open, and the other end is a closed surface. The cover sheet 101 fits with the opening end of the housing 100 and is bonded to the opening end of the housing 100 . The copper foil 102 includes an upper surface and a lower surface, and the lower surface is bonded to the inner bottom surface of the closed surface of the housing 100 . The piezoelectric wafer 103 includes an upper surface and a lower surface, and the lower surface of the piezoelectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com