Washing method of washing machine, control device and washing machine

A washing method and washing machine technology, which are applied to the control device of washing machines, washing devices, other washing machines, etc., can solve problems such as poor user experience, wear, deformation, and weak washing degree, and achieve improved user experience, small deformation, and High cleanliness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Such as figure 1 Shown, the washing method of washing machine of the present invention comprises the following steps:

[0058] S101: The washing machine executes the first preset washing program according to the received washing instruction. The first preset washing program includes the first step of controlling the pulsator 10 and / or the washing tub 20 to rotate in a single direction for a certain period of time and then stop, so that the washing water Under the action of inertia, it collides with the wall of the washing tub to generate waves for washing away the laundry.

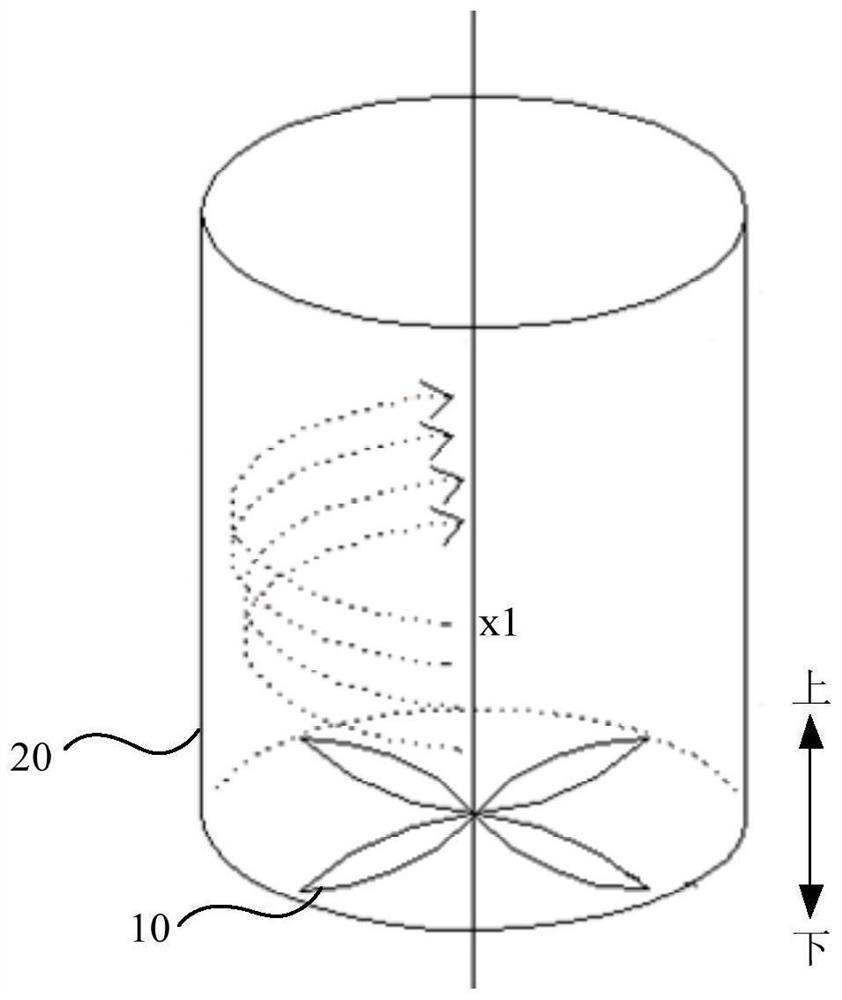

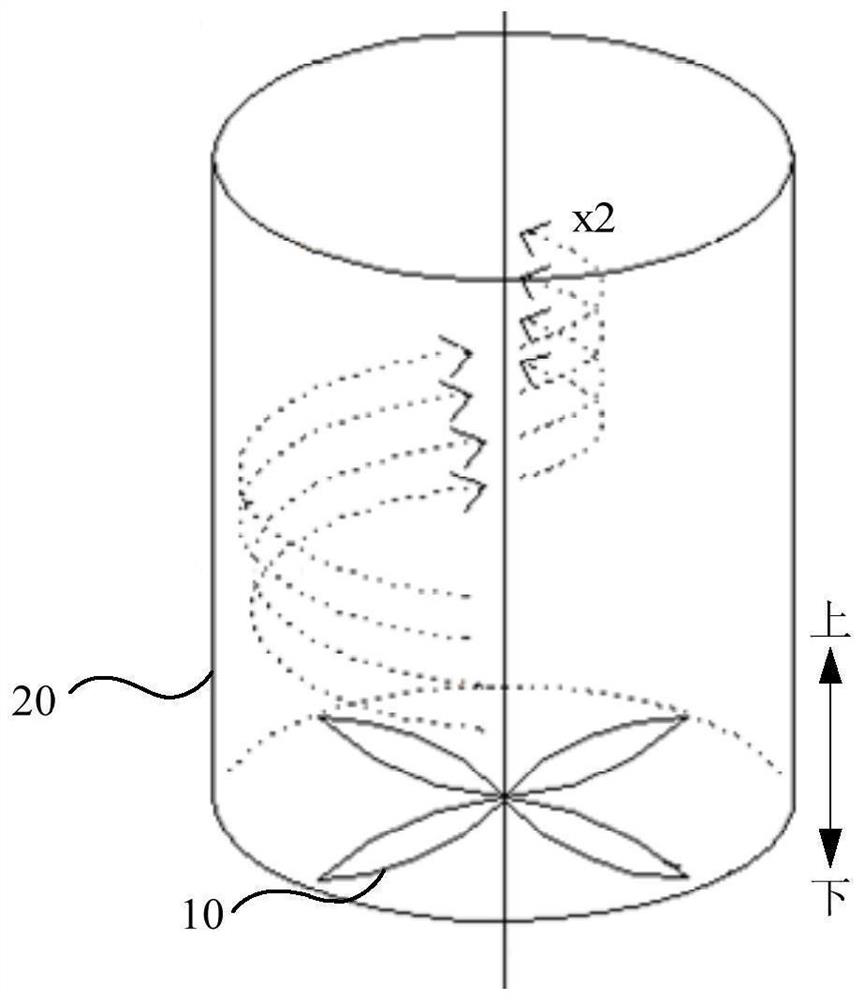

[0059] In the present invention, the washing machine has a first preset washing program. In the first preset washing program, at least one of the pulsator 10 and the washing tub 20 is controlled to rotate in a single direction (for example, clockwise or counterclockwise) for a certain period of time. At this time, if figure 2 As shown, the washing water in the washing tub 20 rotates in the same s...

Embodiment 2

[0064] Compared with the first embodiment above, this embodiment is further limited: in the first step, after the control pulsator 10 and the washing tub 20 jointly rotate in a single direction for a first preset time length, the control pulsator 10 and the washing tub 20 jointly maintain Stop for a second preset duration.

[0065] First, this embodiment further defines that in the first step, the control pulsator 10 and the washing tub 20 jointly rotate in a single direction. For example, in the first step, the control pulsator 10 and the washing tub 20 jointly rotate clockwise (or counterclockwise). In this way, during the rotation process, the pulsator 10 and the washing tub 20 jointly drive the washing water and the laundry to rotate synchronously, so that there is no relative movement between the pulsator 10, the washing tub 20, the washing water, and the laundry, and the laundry There will be no relative friction with the pulsator 10 and the washing tub 20, further avoid...

Embodiment 3

[0082] This embodiment is further defined on the basis of the second embodiment above: the washing machine has a speed reduction clutch device, wherein the first step specifically includes: controlling the speed reduction clutch device to be in a dehydration state, and controlling the motor to run at a speed lower than the dehydration speed.

[0083] In this embodiment, by controlling the speed reduction clutch device to be in the dehydration state during the washing process, the synchronous rotation of the pulsator 10 and the washing tub 20 is realized during the washing process, and the rotation speed is reduced by controlling the motor, the control method is simpler, and the present embodiment The embodiment only needs to control the operation of the deceleration clutch device, and does not need to improve the structure of the existing washing machine, the modification cost is lower, and it is more suitable for market promotion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com