Boost reactor device

A voltage-boosting and piezoelectric technology, applied in transformer/inductor magnetic core, transformer/inductor cooling, transformer/inductor coil/winding/connection, etc., can solve the problem that the main body of the reactor cannot improve the cooling of the upper part of the main body of the reactor Effects, excess space, violations of compactness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

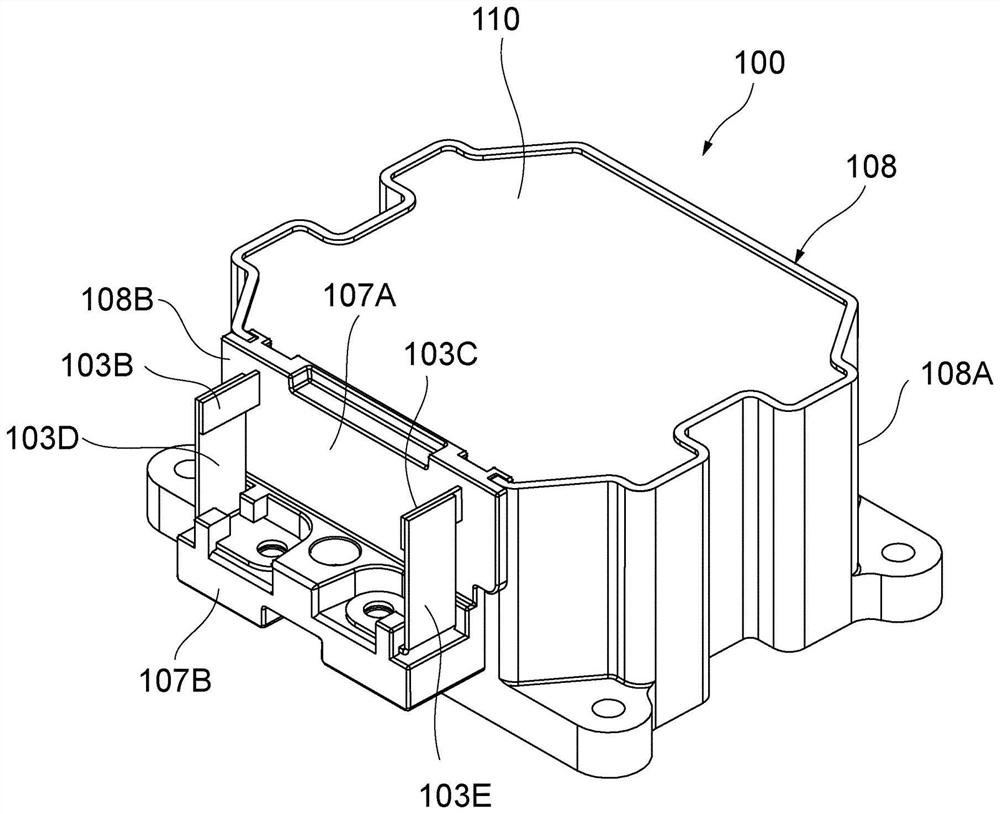

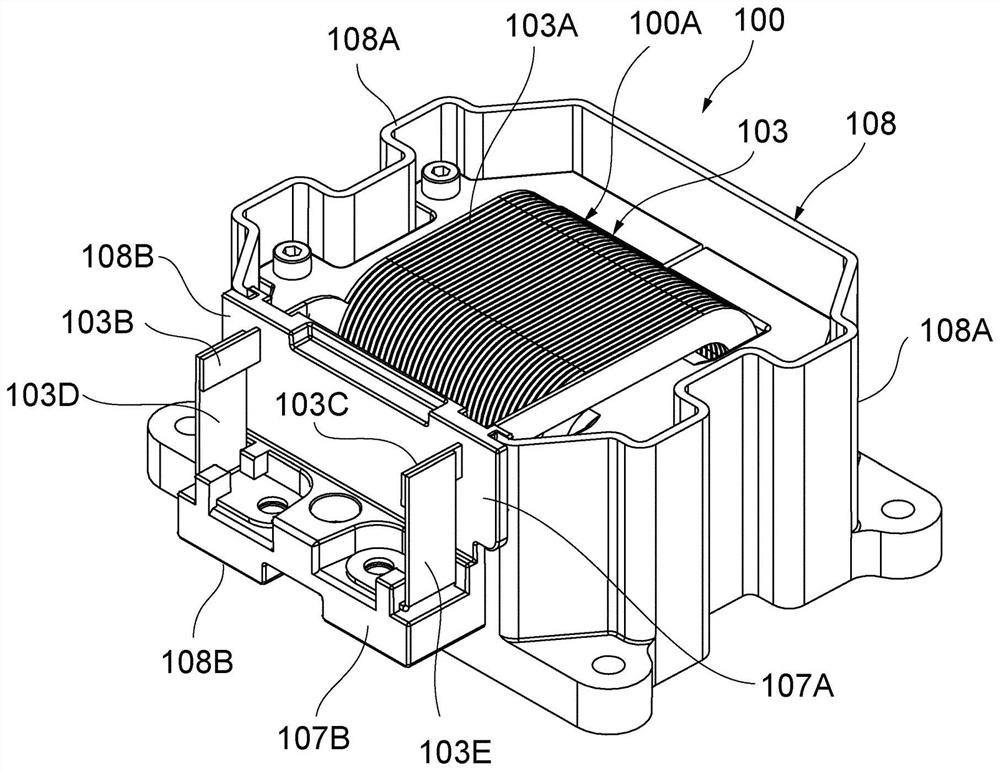

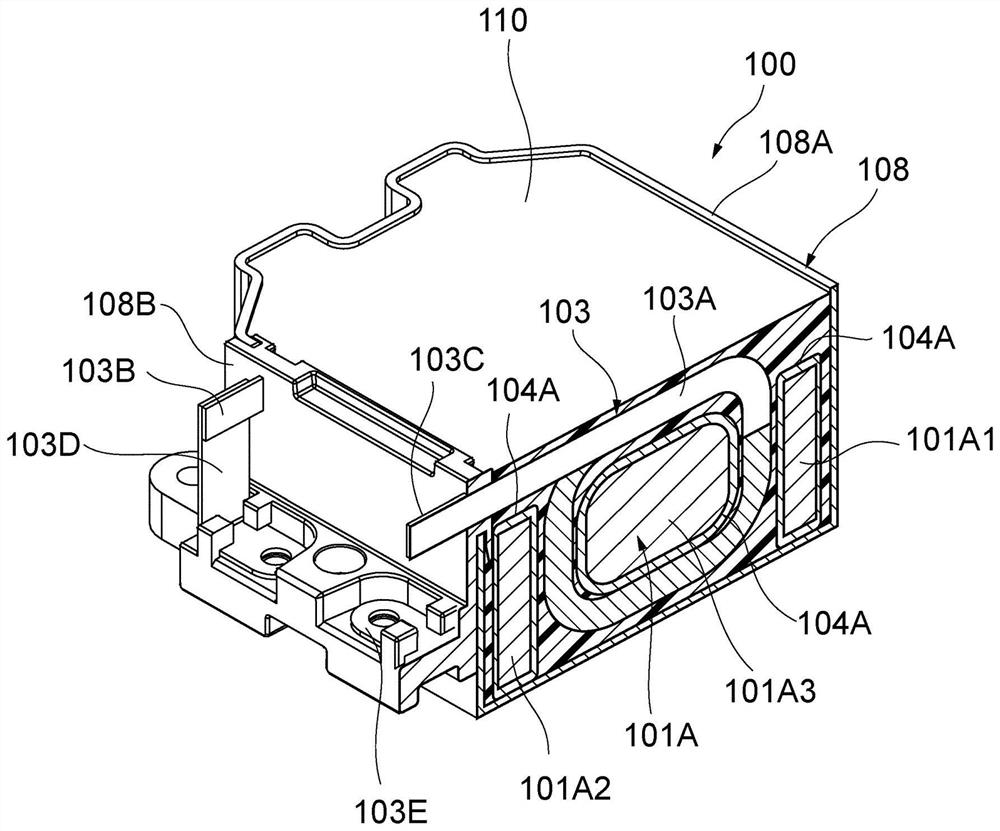

[0063] Below, use appropriately Figure 1A , Figure 1B as well as Figure 2-5 A boost reactor device according to an embodiment of the present invention will be described. The boosting reactor device 100 of the present embodiment includes: a metal case 108 whose upper part is open and made of a material having good thermal conductivity such as metal (aluminum, etc.); and a reactor assembly 100A housed in the metal case. The interior is mainly composed of E-shaped cores 101A, 101B (refer to Figure 5 (a)) and the coil part 103; and the filler 110 for cooling, which is injected between the metal case 108 and the reactor assembly 100A, and has insulating properties.

[0064]

[0065] The boost reactor device 100 according to the embodiment of the present invention includes a pair of E-shaped cores 101A and 101B (see Figure 5 (b)). The two E-shaped cores 101A, 101B pass through respective leg portions (outer leg core portions 101A1, 101B1, middle leg core portions 101A3, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com