Fault-tolerant anti-interference control method for vertical reduction system of rolling mill under typical working condition

A vertical reduction, system fault-tolerant technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of rolling fluctuations and oscillations, destroying the structure of continuous rolling mills, and stopping immediately, so as to improve the quality and accuracy of the sheet , to ensure the closed-loop stability, the effect of suppressing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

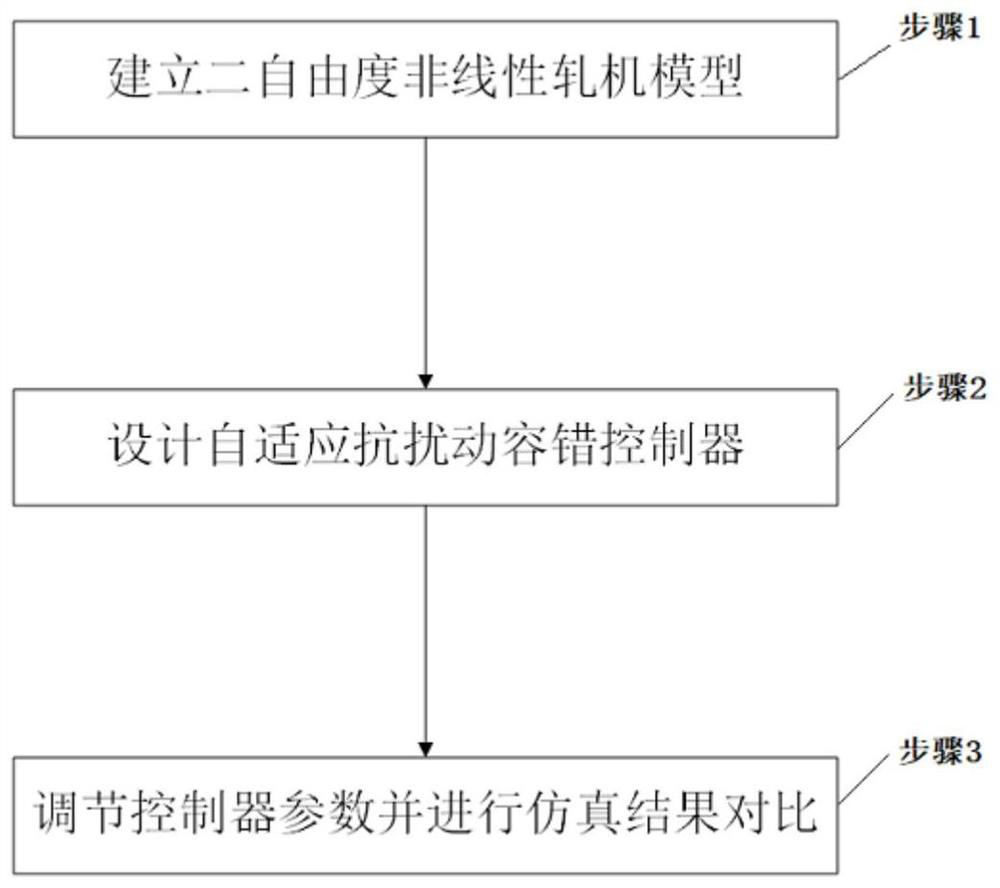

Method used

Image

Examples

Embodiment Construction

[0104] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

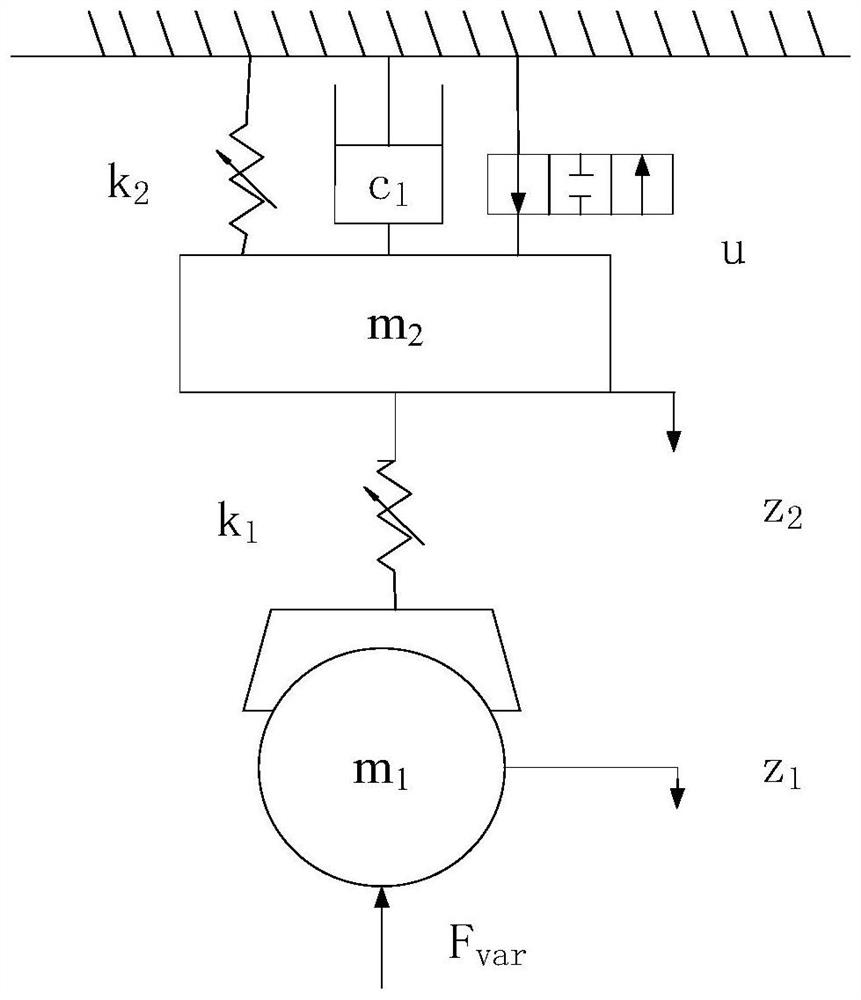

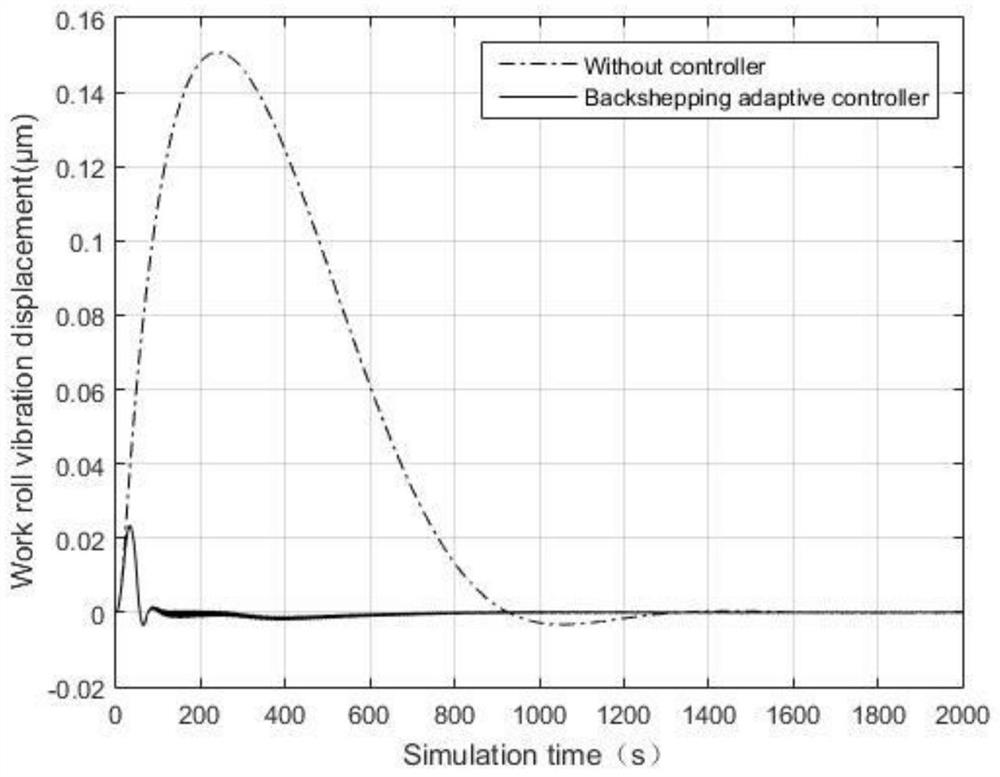

[0105] In the vertical pressing system of the rolling mill, due to the drastic load changes during the rolling process, the output of the controller’s electro-hydraulic servo valve and hydraulic cylinder cannot follow and resist disturbances during the feedback control, and the output direction of the controller is opposite to the expected control direction. At this time The system will oscillate. At the same time, due to the deviation of the installation position and the individual differences of the mechanical structure, the structural stiffness of the system actually has a certain degree of perturbation. The above reasons make the anti-disturbance control strategy of the rolling mill vertical reduction system in the rolling process an extremely complicated problem.

[0106] In the vertical reduction system of the rolling mill, the acquisition of some...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com