Assembly process for intelligent audio module production

An assembly process and audio technology, applied in the direction of manufacturing tools, metal processing, auxiliary devices, etc., can solve the problems of reducing production efficiency, prolonging the process flow, increasing the workload of production personnel and production time, etc., to improve production efficiency and shorten the process. process, the effect of reducing product surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

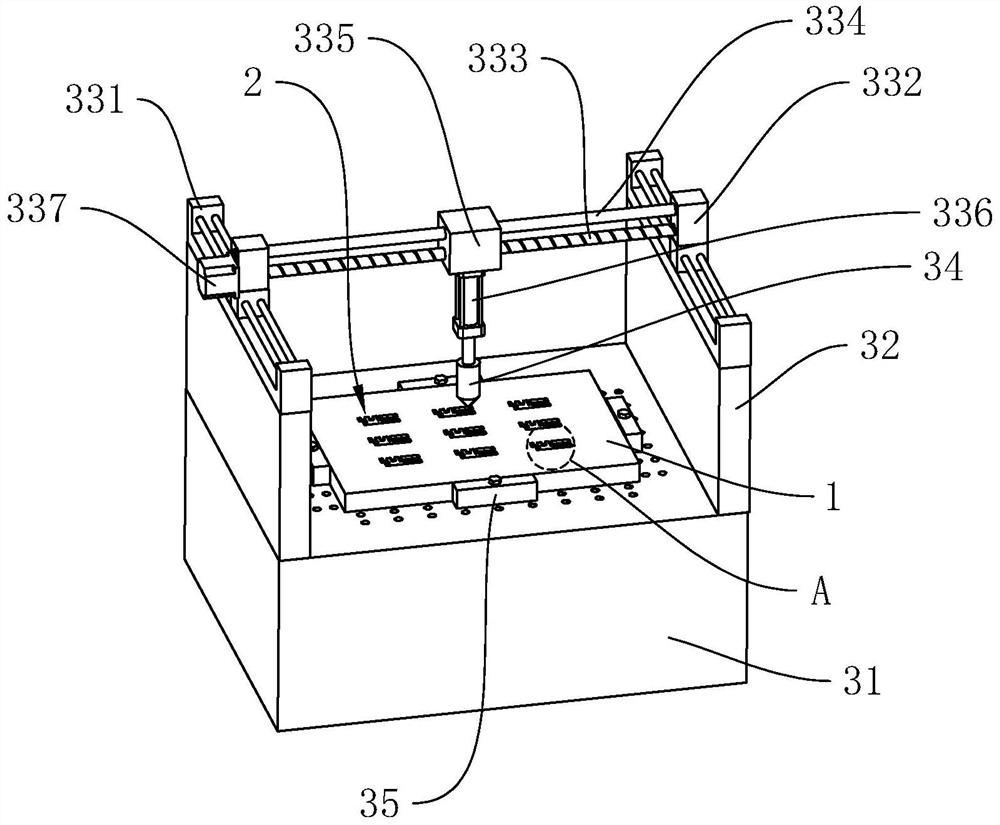

[0043] The following is attached Figure 1-3 The application is described in further detail.

[0044] The embodiment of the present application discloses an assembly process for producing an intelligent audio module. refer to figure 1 , an assembly process for the production of an intelligent audio module, comprising the following steps:

[0045] S1. First use adhesive tape to plug the holes of the components to be welded;

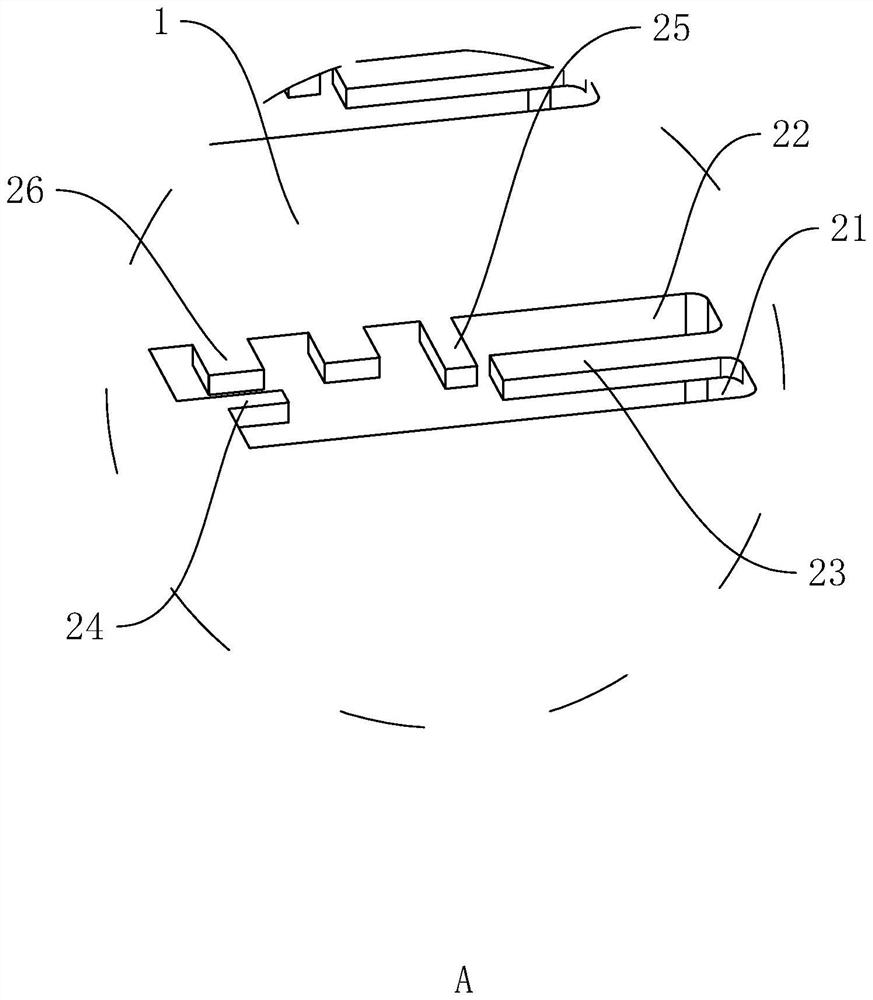

[0046] S2, fixing the components and the FPC with the plug holes completed using the welding jig 1;

[0047] S3. Put the welding jig 1 that has fixed the components and the FPC on the automatic welding device 3 and fix it;

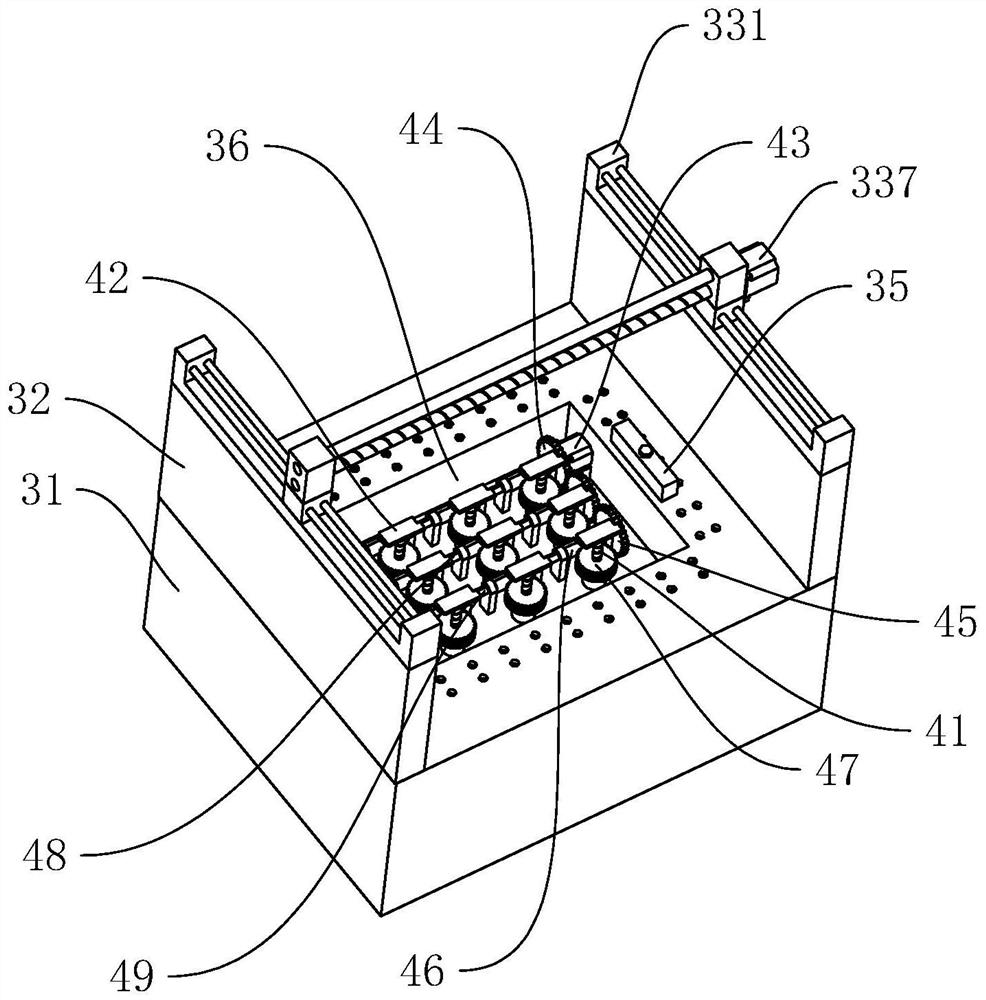

[0048] S4. Start the auxiliary positioning component 4 to assist in positioning the components and the characteristic parts of the FPC;

[0049] S5. Start the automatic welding device 3 to automatically weld the components and the FPC.

[0050] By plugging the components, the holes of the components can be protected, the componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com