Extruded plastic plate cooling and shaping equipment of screw extruder

A screw extruder and plastic sheet technology, which is applied in the field of extruded plastic sheet cooling and shaping equipment, can solve the problems of plastic sheet sticking to conveying rollers in the degree of cooling, increase the difficulty of plastic sheet processing, and plastic sheet hardening, etc., to prevent lubricants The effect of excessive consumption and increasing the difficulty of production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

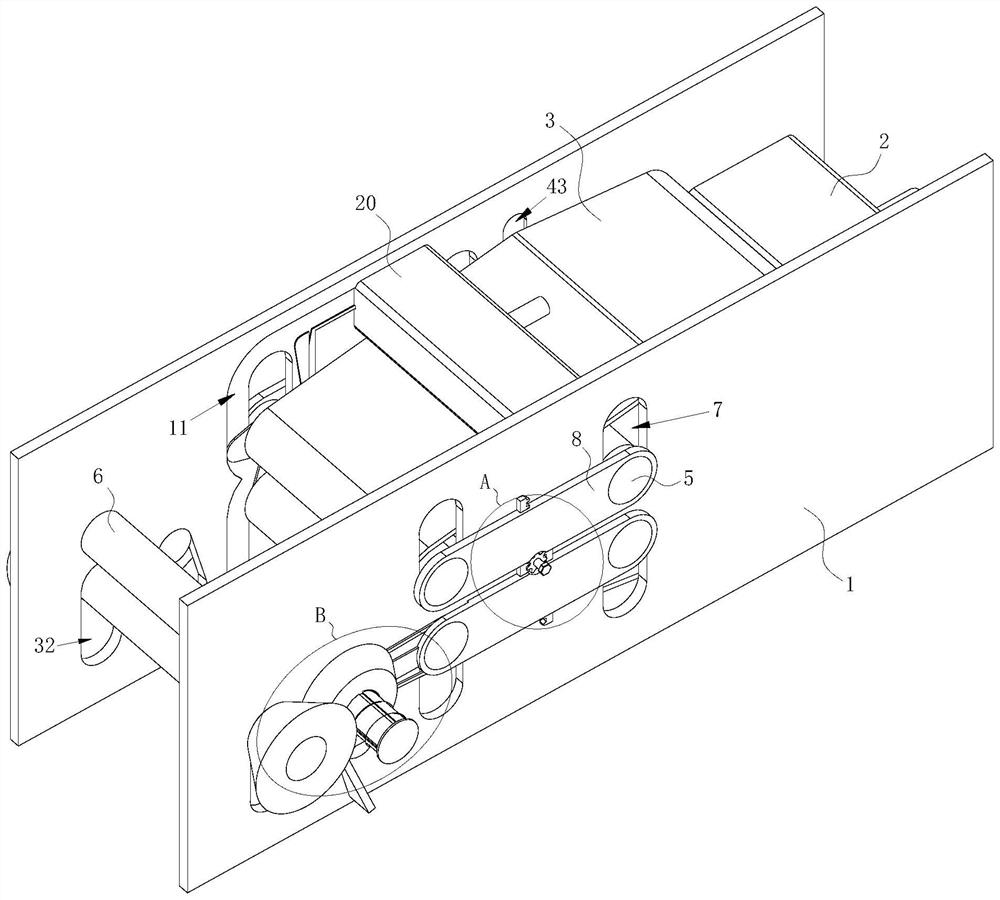

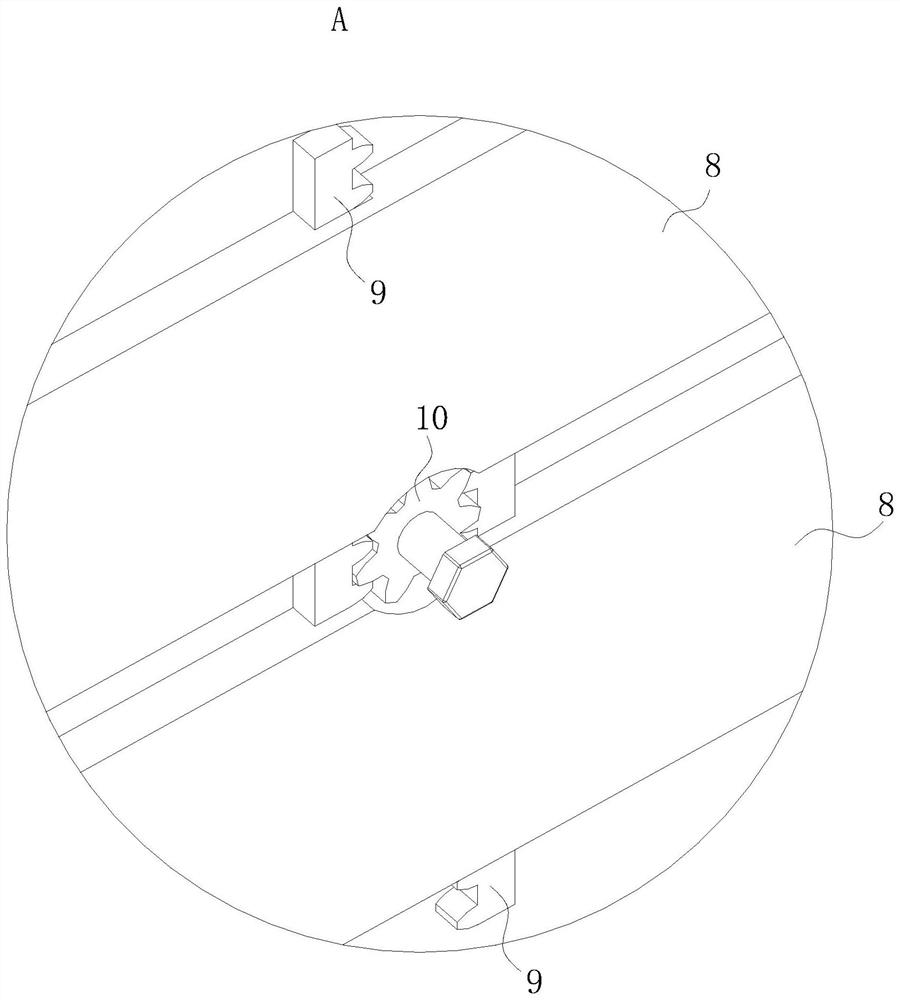

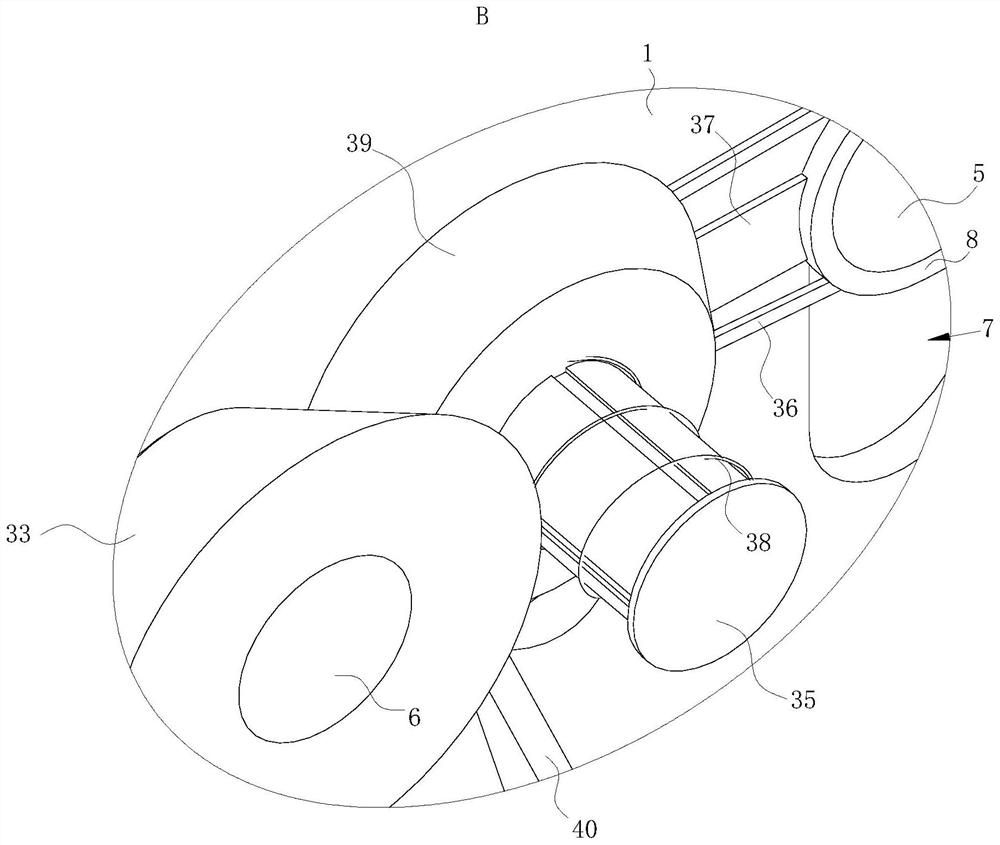

[0031] see Figure 1-11 , the present invention provides a technical solution: a cooling and shaping equipment for extruding plastic sheets of a screw extruder, comprising two mounting plates 1 arranged opposite to each other, and a screw extruder is arranged between the two mounting plates 1 Extrusion end 2, two extrusion belts 3 are arranged between the two installation plates 1, and the two extrusion belts 3 are driven by a rotating roller 4 and two adjustment rollers 5 to rotate synchronously and in reverse. The belt 3 is arranged oppositely and is located at the side of the extruding end 2 that can extrude the plastic sheet. Two parallel stretching rollers 6 are arranged between the two mounting plates 1, and the stretching roller 6 is located at a distance from the extruding end 2. On the side, the surfaces of the two mounting plates 1 are provided with adjustment mechanisms corresponding to the positions of the two extrusion belts 3. The adjustment mechanisms are used t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap