Asphalt storage device for road construction

A storage device and road construction technology, applied in packaging, transportation and packaging, railway car body parts, etc., can solve the problems of affecting the laying effect, inconsistent asphalt fluidity, and uneven heating, so as to avoid the reduction of cleaning effect and uniform heating , the effect of avoiding material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

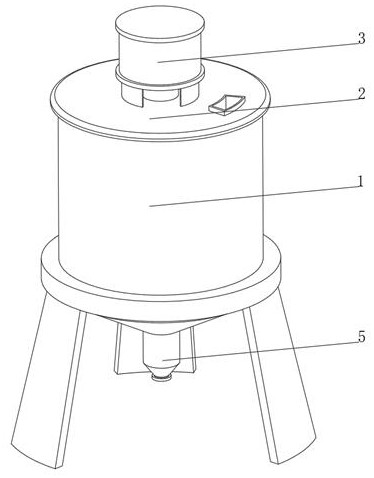

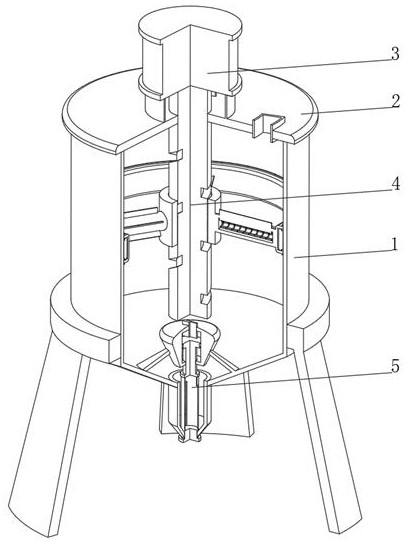

[0035] see Figure 1-Figure 3 , the present invention provides a technical solution: an asphalt storage device for road construction, specifically comprising:

[0036] Storage barrel 1, the top of the storage barrel 1 is fixedly connected with a top cover 2, the top center of the top cover 2 is fixedly connected with a drive motor 3 through a bracket, and the top of the top cover 2 is provided with a feeding port;

[0037] A heating device 4, the heating device 4 is arranged inside the storage barrel 1, the top of the heating device 4 penetrates the top cover 2 and is fixedly connected with the drive shaft of the drive motor 3;

[0038]A discharge device 5, the discharge device 5 is arranged at the bottom of the storage bucket 1, and the top of the discharge device 5 communicates with the inside of the storage bucket 1;

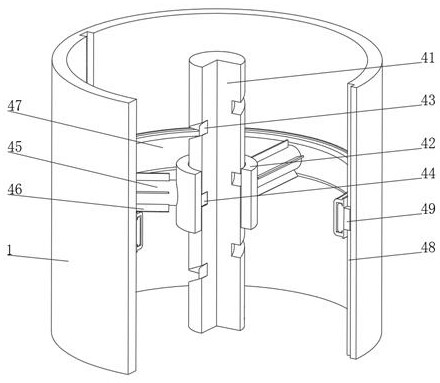

[0039] Heating device 4 comprises:

[0040] Rotating rod 41, the outer side of the rotating rod 41 is sleeved and slidably connected with a sliding sleeve ...

Embodiment 2

[0048] see Figure 1-Figure 4 On the basis of Embodiment 1, the present invention provides a technical solution: the cleaning ring 47 includes a scraping ring 471, the bottom of the scraping ring 471 is fixedly connected with an oblique retaining ring 472, and the outer side of the scraping ring 471 is provided with an expansion groove 475, and the inner wall of the expansion groove 475 Fixedly connected with an expansion air bag 474, the top of the expansion air bag 474 is provided with an inflation port, the outer side of the scraping ring 471 is covered with a friction ring 473, one side of the friction ring 473 extends to the inside of the expansion groove 475 and is slidingly connected with the inner wall of the expansion groove 475, the scraping ring 471 The inner wall is fixedly connected to the end of the heating rod 45 away from the sliding sleeve 42. The inflation port on the top of the inflatable airbag 474 runs through the scraping ring 471 and extends to the top of...

Embodiment 3

[0050] see Figure 1-Figure 5 , On the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the discharge device 5 includes a discharge pipe 51, a control seat 52 is arranged on the top of the discharge pipe 51, and an expansion cavity is opened inside the control seat 52 53, the inner wall of the expansion cavity 53 is slidably connected with an expansion piston 54, one side of the expansion piston 54 is fixedly connected with a push rod 55, and the end of the push rod 55 away from the expansion piston 54 runs through the expansion cavity 53 and is fixedly connected with a connecting pipe 56, which is Both sides of 56 are provided with discharge holes 57, the bottom of connecting pipe 56 is fixedly connected with plug 58, the top of discharge pipe 51 communicates with the bottom of storage bucket 1, and the control seat 52 is fixed on the bottom of the inner wall of storage bucket 1 by a bracket. The end away from the communication pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com