Feeding mechanism for bearing detection machine and working method of feeding mechanism

A technology of feeding mechanism and working method, which is applied in the direction of conveyors, conveyor objects, packaging, etc., can solve the problems that the bearing is placed in the center of the conveyor belt, affects the detection work, and needs to be improved, and achieves the effect of simple adjustment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

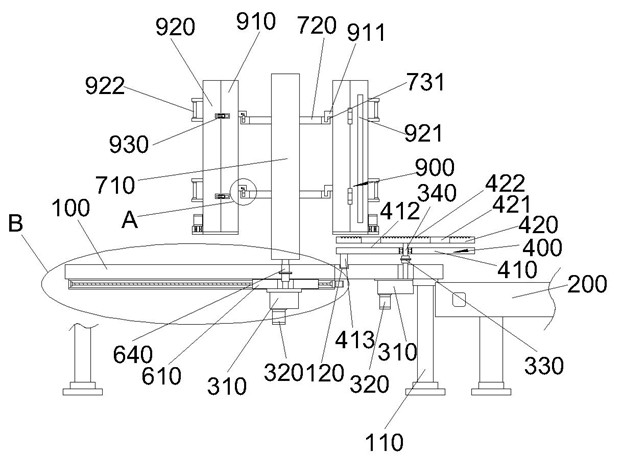

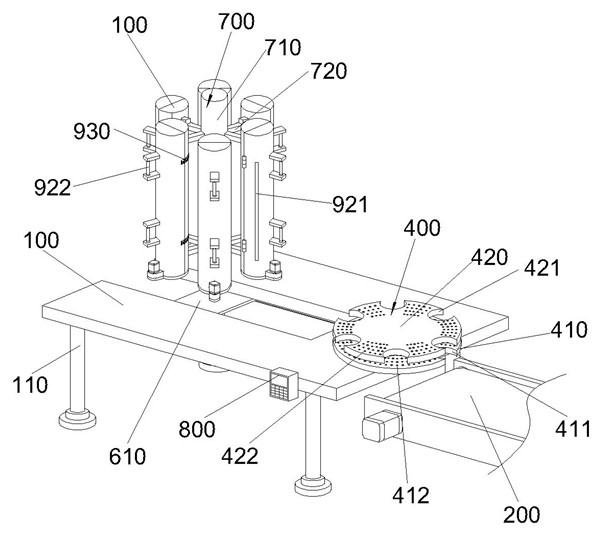

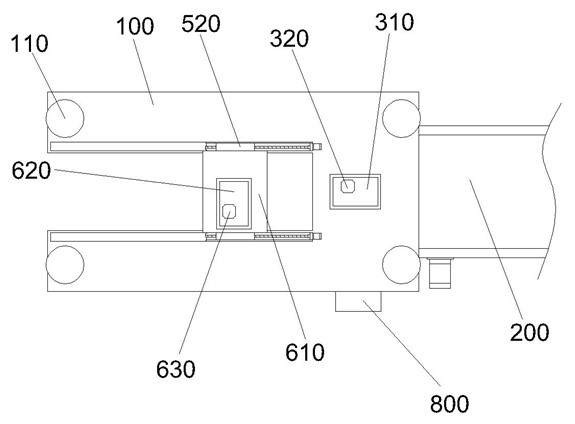

[0034] see Figure 1-Figure 9 , the present invention provides the following technical solutions: a feeding mechanism for a bearing inspection machine and its working method, including a feeding device base 100, a support column 110 is installed on the bottom of the feeding device base 100, and the feeding device The bottom of the device base 100 is provided with a feeding conveyor belt 200, and the bottom of the feeding device base 100 is equipped with a first reduction box 310, and the input shaft of the first reduction box 310 is fixedly connected with the output shaft of the first servo motor 320 , the output shaft of the first reduction box 310 passes through the top of the feeding device base 100 and is fixedly connected to the bottom of the first coupling 330, and the top of the first coupling 330 is equipped with a first connecting shaft 340, The first connecting shaft 340 is installed on the feeding device 400, and two slide rails 510 are installed on the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com