Metal profile bearing platform anchoring foundation for power transmission line truss

A technology for metal profiles and transmission lines, applied in infrastructure engineering, construction, protection devices, etc., can solve the problems of heavy weight, large reinforced concrete bearing platform, inconvenient transportation and installation, etc., to shorten the construction period and improve assembly. The effect of application rate and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

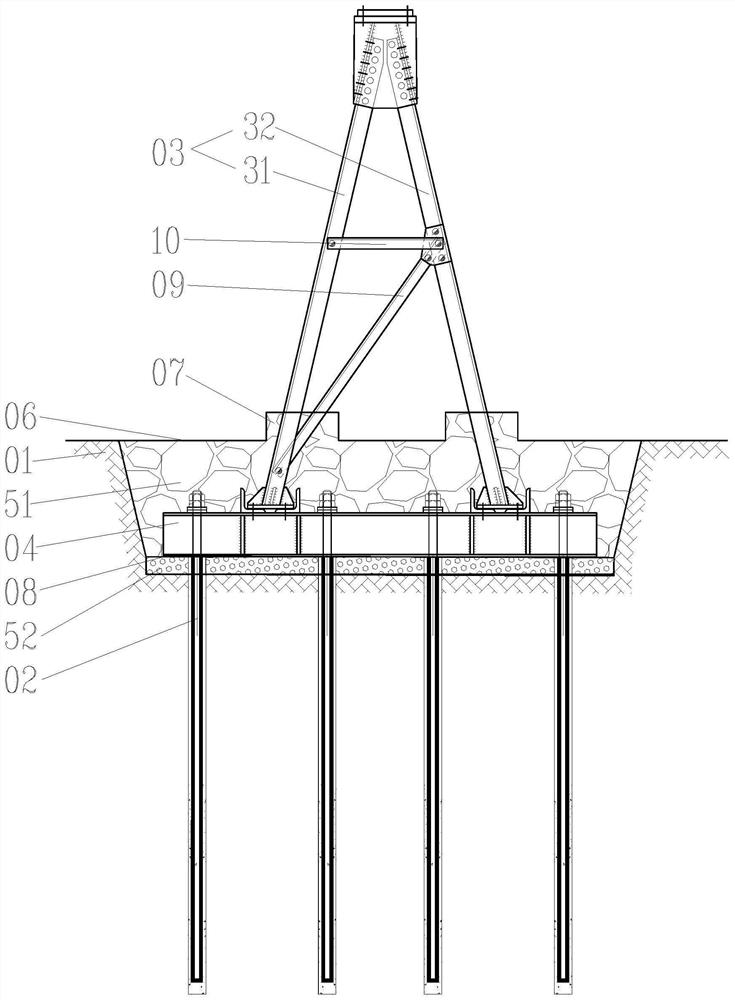

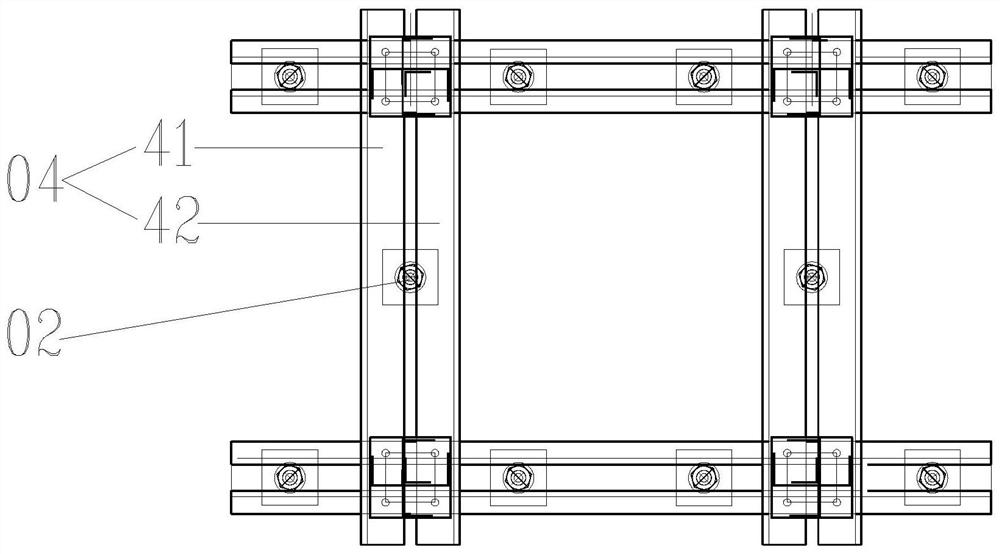

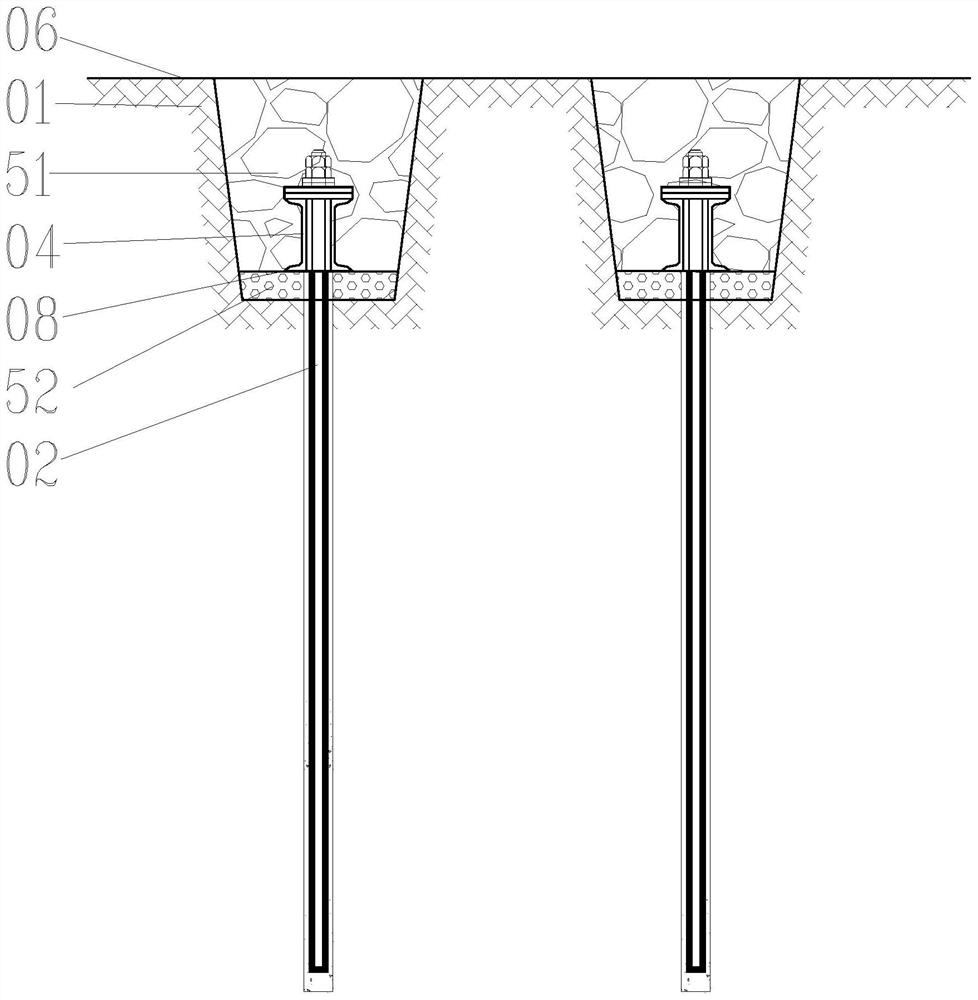

[0022] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure, the directions and relative positions of up and down all refer to figure 1 In the upper and lower directions and relative positions, the vertical direction is figure 1 The vertical direction arranged in , the horizontal direction is perpendicular to the vertical direction, the metal profile cap anchor foundation for the transmission line truss in this embodiment includes foundation 01, assembled metal profile cap, anchor rod 02 and The metal bracket, the assembled metal profile bearing platform includes several metal profiles 04 interconnected to form a closed structure, the metal profiles 04 are at least two; the foundation 01 is dug with the original groove for installing the assembled metal profiles 04 , the assembled metal profile cap is fixed to the original tank through the anchor rod 02, the metal bracket is fixed to the assembled metal profile cap, and the orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com