Coal seam gas pressure and concentration integrated detection device

A technology of coal seam gas pressure and detection device, which is applied to measurement devices, mining devices, fuel oil testing, etc., can solve the problems of increasing detection equipment, difficult secondary utilization, and a large number of detection tubes, and achieves the effect of reducing detection interference and quick disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

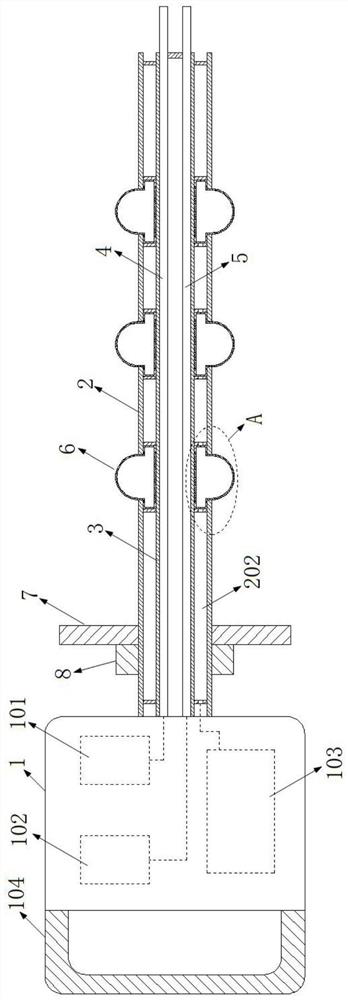

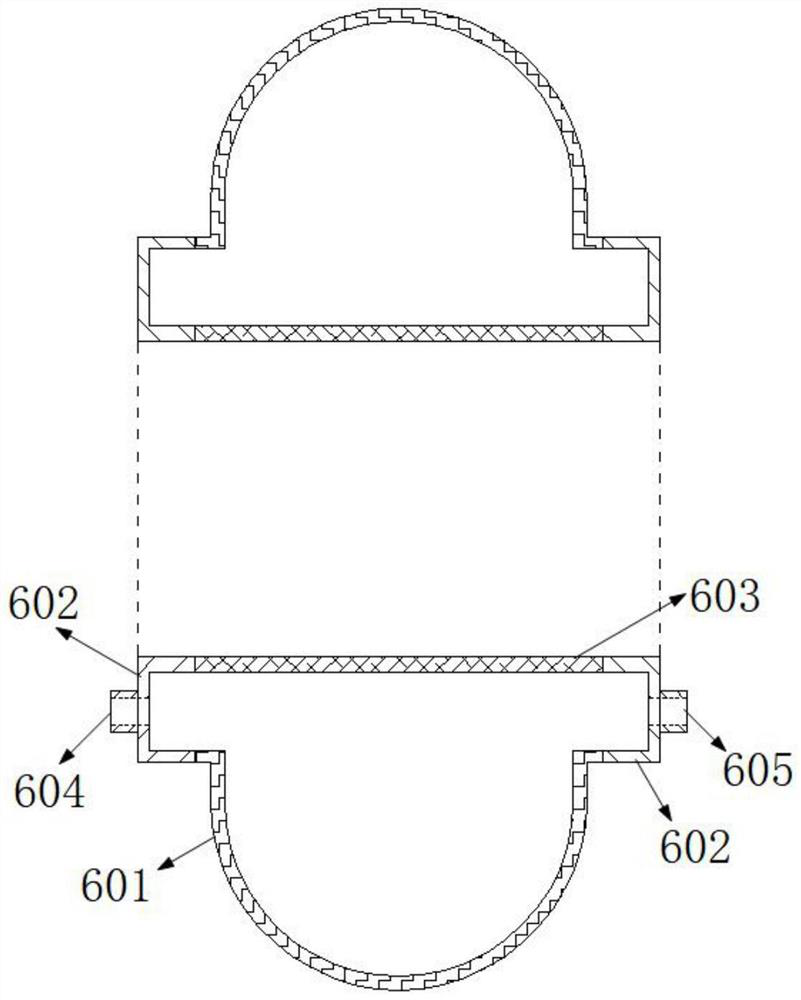

[0027] The detection terminal 1 of the coal seam gas pressure and concentration integrated detection device is equipped with a gas pressure detection module 101 , a gas concentration detection module 102 and a capsule driving control module 103 . The detection terminal 1 is fixedly connected with an outer sleeve 2, the outer sleeve 2 is divided into multiple sections, and the expansion balloon 6 is installed in the groove in the middle of the adjacent section of the outer sleeve 2.

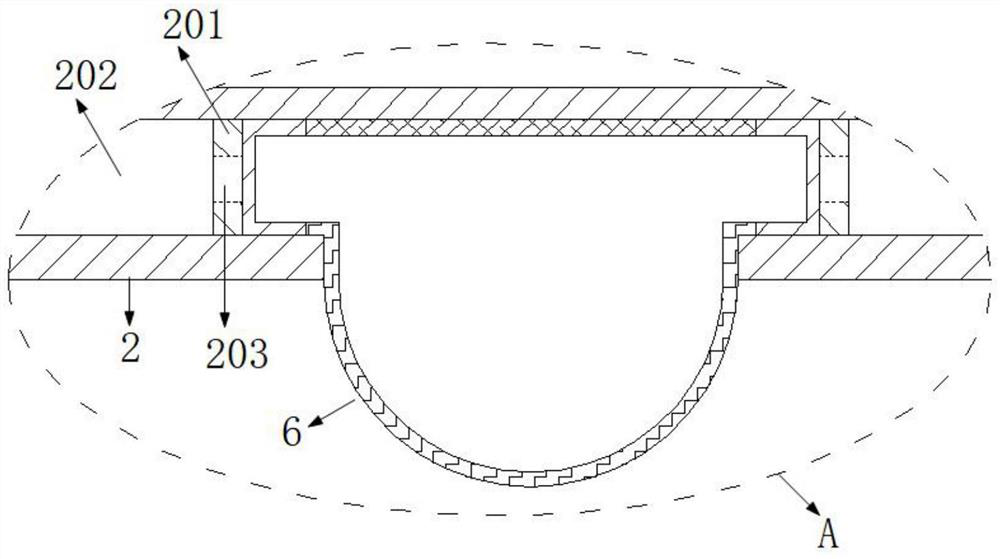

[0028] The outer casing 2 is fixed with an inner casing 3, and between the outer casing 2 and the inner casing 3 are fixed several groups of partition ring plates 201, and each group of partition ring plates 201 forms a diversion cavity 202, and the non-tail end A group of partition ring plates 201 on the side are provided with diversion openings 203, and the bladder control module 103 is equipped with a hydraulic storage box, and the external connecting pipe of the hydraulic storage box is connect...

Embodiment 2

[0033] The coal seam gas pressure and concentration integrated detection device is used for detection. First, the coal seam to be sampled is drilled, and the outer casing 2 with the expansion capsule 6 in a contracted state is inserted into the borehole. After being inserted in place, the capsule driving and controlling module 103 is activated to hydraulically supplement the inflatable capsules 6 in the contracted state. Under the action of hydraulic pressure, the inflatable capsules 6 in the contracted state start to expand and adapt to the deformation of the wall surface of the drilled hole at their respective positions. Press the contact to form a multi-channel seal and support in the drilling channel, and then move the external positioning plate 7 to the outer base surface of the drilling position to contact, and use the reinforcement nut 8 to reinforce the external positioning plate 7, so that the entire detection device Installed at the position of gas detection, it start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com