Shield excitation quantitative determination probe and method thereof

A quantitative detection and excitation technology, applied in the field of detection, can solve the problems of stray detection signals and poor reliability, and achieve the effect of reducing magnetic energy loss and mutual interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

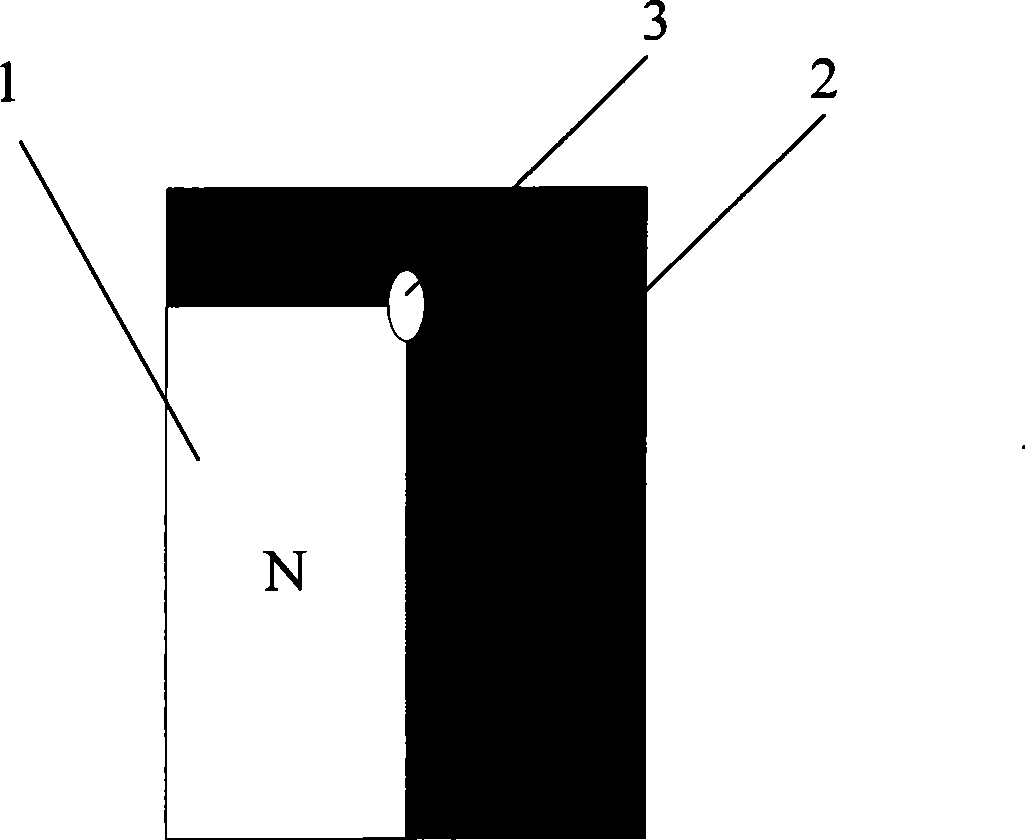

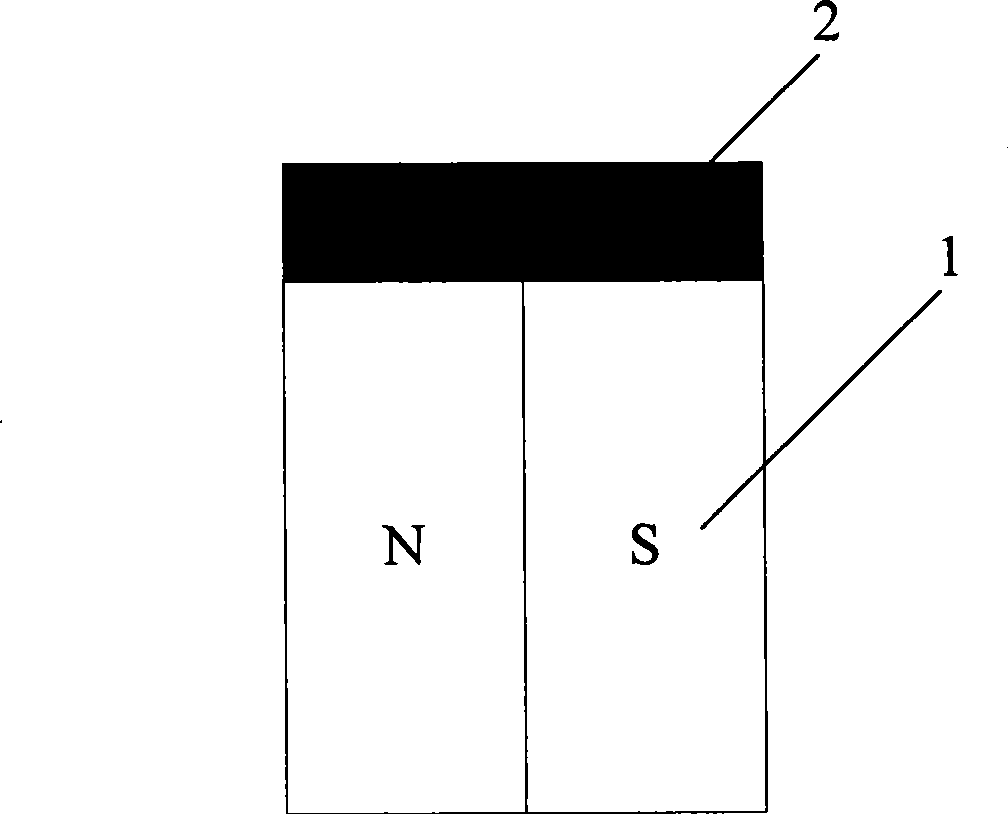

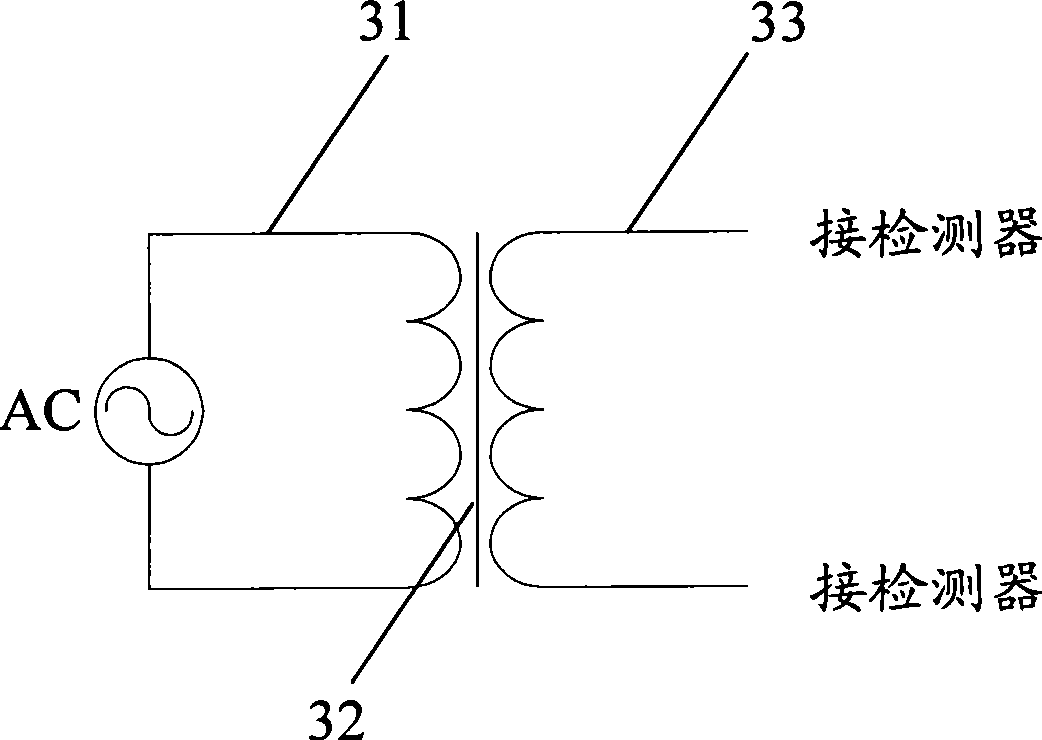

[0054] In view of the above reasons, this embodiment adopts an L-shaped shielding element to shield a lateral side portion of a rectangular constant permanent magnet and the S pole portion of the non-working surface, so that the magnetic field strength of the non-working surface of the probe is less than or equal to the magnetic field strength before shielding 2%. The L-shaped shielding element is made of permalloy or pure iron. In addition, the L-shaped shielding element can increase the utilization rate of the magnetic field strength of the rectangular constant permanent magnet by at least 30%. In this way, the probe can be made small and thin, reducing the loss of magnetic energy and the influence of the surrounding environment on the probe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com