Light-emitting device and bulb

A light-emitting device and light bulb technology, applied in the field of lighting, can solve the problems of low light efficiency, burnt P-N junction, and decreased luminous efficiency, and achieve the effects of small size, large power controllable range, and improved heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

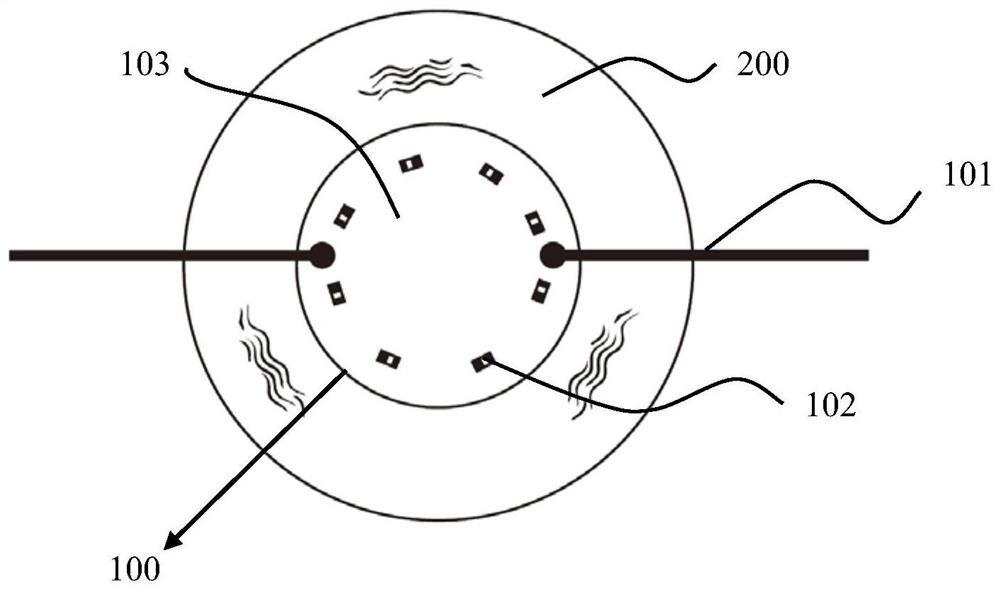

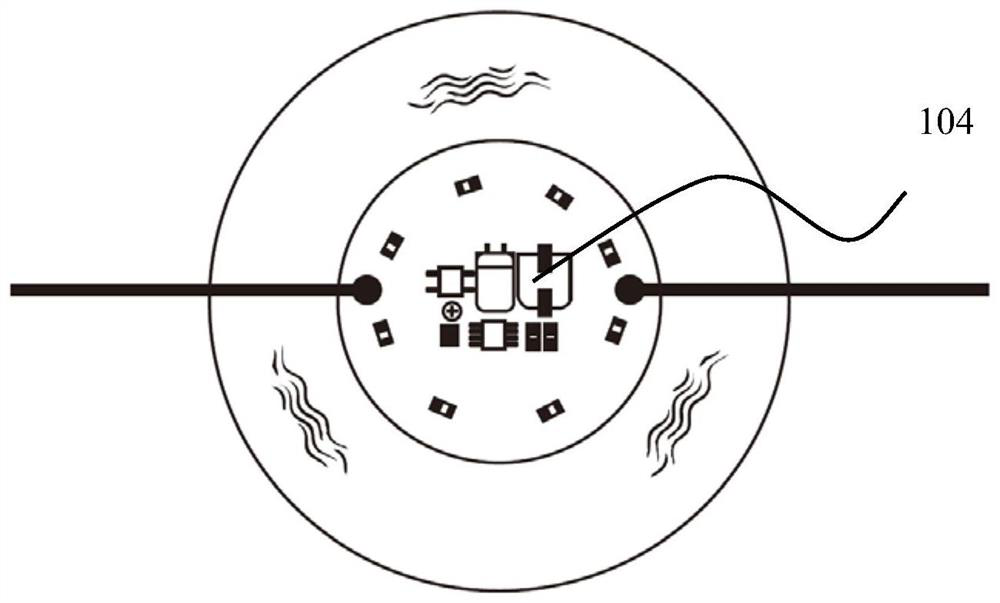

[0042] a lighting device such as figure 1 , including a light engine structure, the light engine includes a light source 100 and a first sealed cavity 200, the light source is placed in the first sealed cavity, the first sealed cavity is filled with insulating liquid, the first sealed cavity The light source in the cavity is exposed to the insulating liquid; a second sealed cavity 300 is provided outside the first sealed cavity, and the second sealed cavity is filled with insulating gas;

[0043] The light source includes pins 101, and the pins protrude from the first sealed cavity to the second sealed cavity;

[0044] The first sealed cavity is a translucent, light-transmitting sealed cavity, and the second sealed cavity is a fully transparent, light-transmitted sealed cavity. The light transmission performance of translucent and light-transmitting materials is equivalent to that of transparent materials, but the translucent material can reduce the glare of the light source....

Embodiment 2

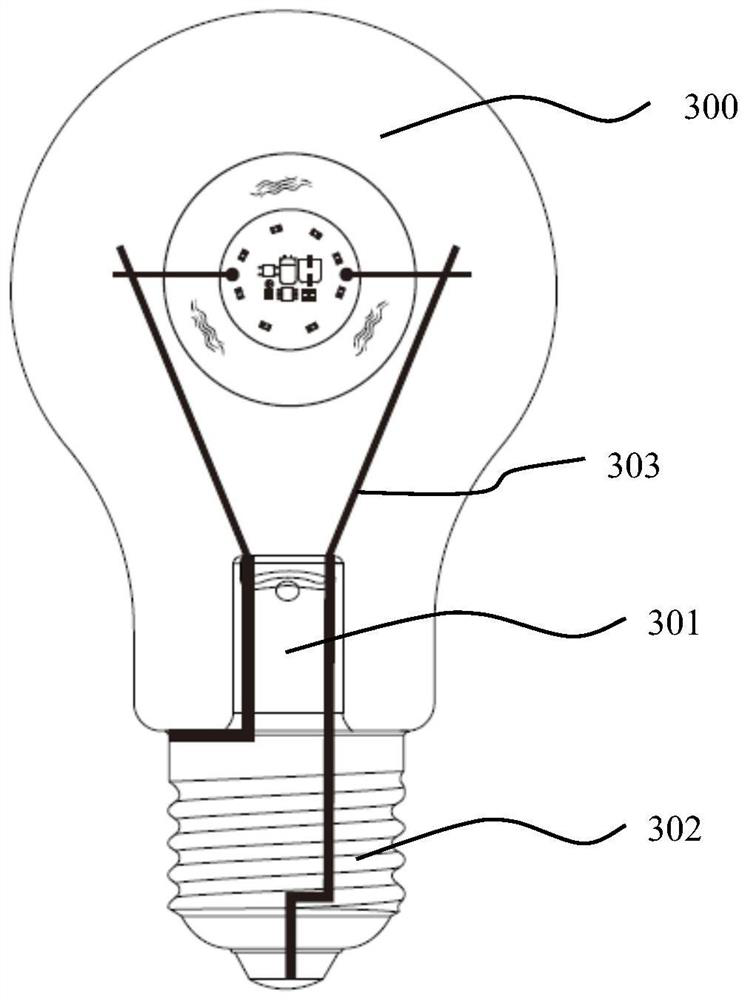

[0065] This embodiment discloses a light bulb, such as image 3 , the light bulb structure includes the light-emitting device described in Embodiment 1, and also includes a stem 301 and a lamp cap 302, and the lamp cap and the stem are connected to the housing of the second sealed cavity 300 (ie, the bulb of the bulb), and the lamp cap For accessing an external power supply, the casing of the first sealed chamber is fixed to the stem.

[0066] The stem includes a horn tube, a horn base, an electrical lead-out wire and an exhaust pipe, the exhaust pipe is placed in the horn tube, the horn base is sealed and connected to the second sealed cavity, and one end of the electrical lead-out wire is connected to to the lamp head, and the other end is connected to the pin.

[0067] In another embodiment, the driving circuit is placed in the second sealed cavity, and one end of the pin located in the second sealed cavity is connected to the driving circuit.

[0068] Or, in another embo...

Embodiment 3

[0071] like Figure 4 , several bare crystal structures are connected in series or in parallel or combined in series and parallel to form a chain light source 400, the chain light source is wound around the main substrate 401 to realize a 4Π light emitting (360° omnidirectional light emitting) mode, and the main substrate can be shielded in the chain In the middle of the light source. A specific implementation is as follows:

[0072] The chain light source includes several strip-shaped substrates, on which a plurality of connecting lines are arranged, and each connecting line is a bare crystal structure connected in series or in parallel or a combination of series and parallel, thereby forming a filament structure. The chain light sources on each strip substrate can be light sources with the same color temperature or different color temperature light sources. Each connecting line is independently controlled for controlling the filament to emit light of a specific color. Spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com