Method for testing shock wave resistance of electronic control module for electronic detonator

A technology of electronic control modules and electronic detonators, which is applied in the direction of offensive equipment, fuzes, weapon accessories, etc., can solve problems such as impact resistance, lack of anti-static and anti-electromagnetic capabilities, component damage, detonator explosion resistance, etc., to ensure product safety and reliability Effect

Pending Publication Date: 2022-05-10

CHINA COAL TECH & ENG GRP HUAIBEIBLASTING TECHN RES INST

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Most domestic electronic detonator manufacturers adopt the cooperation form of electronic control module outsourcing, and the electronic control modules of different detonator manufacturers come from different electronic design companies, so there are inconsistent electronic control module circuit designs, large differences in device selection, inconsistent performance indicators, and product quality differences. Large, especially the lack of relevant performance detection methods for impact resistance, anti-static, and anti-electromagnetic capabilities

[0003] At present, electronic detonators frequently have the problem of detonator failure in small-section blasting such as tunnels, underground mines, and hole piles, which not only affects the overall effect of blasting operations and construction progress, but also poses serious safety hazards

There are many reasons for the failure of electronic detonators during the use of electronic detonators. However, in the small-section delayed blasting project, the electronic detonators in the delayed timing are affected by the shock waves generated by the first blast holes, and the electronic detonators and their electronic control modules may be damaged. Component damage, failure and energy storage reduction lead to explosion rejection, which seriously affects the popularization and application of electronic detonators

[0004] At present, there have been reports on the test methods and devices for the anti-shock wave performance of electronic detonators, but the test methods for the anti-shock wave performance of electronic control modules used in electronic detonators are lacking.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0032] The method for testing the anti-shock wave performance of the electronic control module for the electronic detonator proposed by the present invention, the method steps are as follows:

[0033] S1: Preparation of the sample to be tested

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

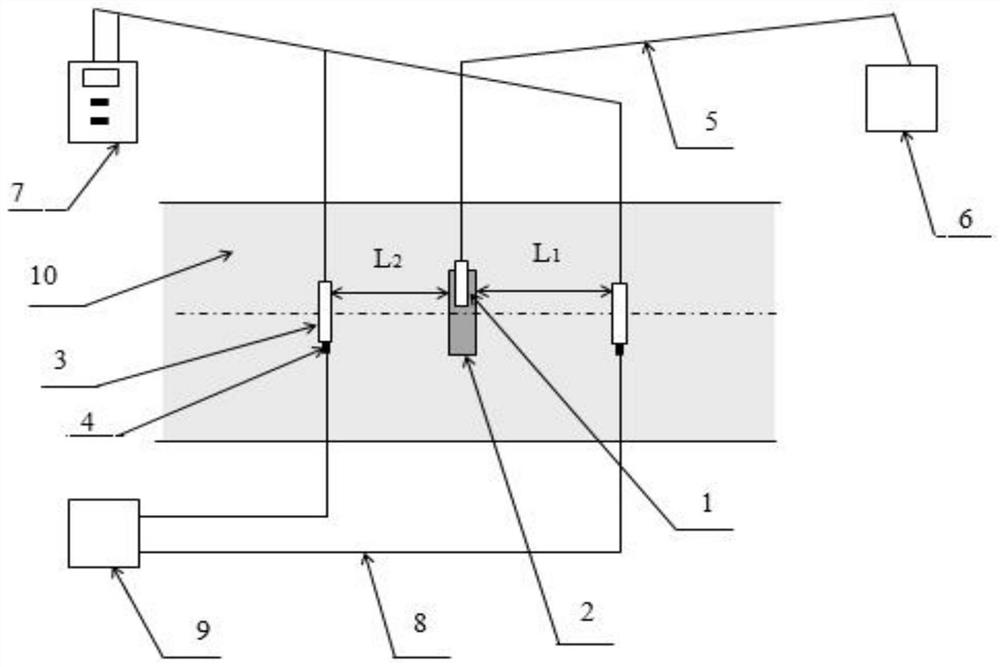

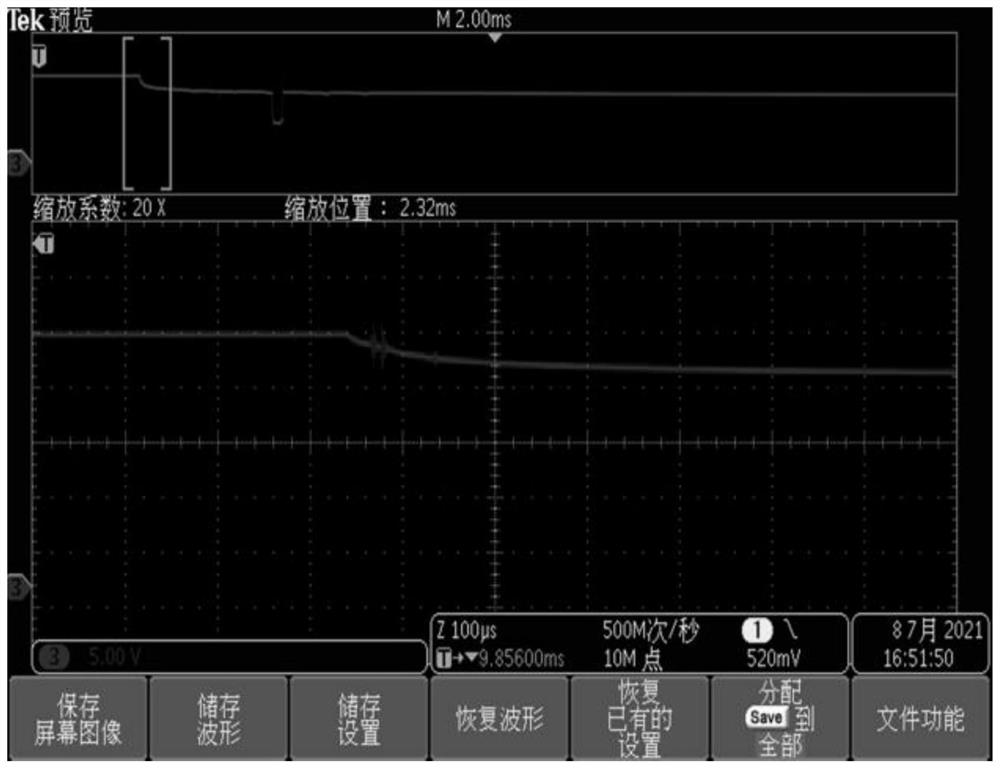

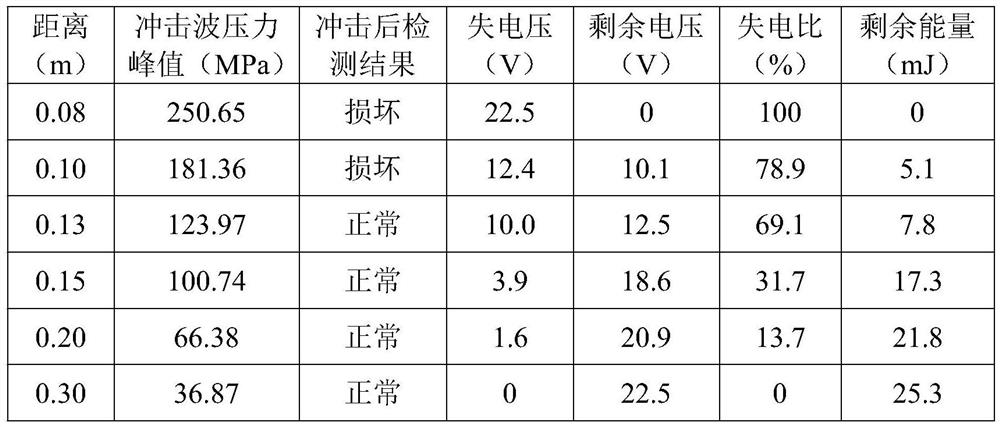

The invention discloses a method for testing shock wave resistance of an electronic control module for an electronic detonator. The method comprises the following steps: S1, preparing a tested sample; s2, fixing the tested sample: fixing the tested electronic control module sample and an explosive charge in a steel frame, keeping the centers on the same straight line, then adjusting the distance L between the tested electronic control module sample and the explosive charge, controlling the shock wave intensity of the tested electronic control module sample, and then putting the steel frame into an explosion water tank; s3, setting delay time and detonating; s4, collecting and processing data; and S5, determining the shock wave resistance of the tested electronic control module. According to the invention, the damage state of the electronic control module in a working timing state under the action of explosive shock waves and the internal energy storage change at the moment of impact can be directly simulated, and the shock wave resistance of the electronic control module is investigated; the method can be used as a preposed process for controlling the shock wave resistance of the electronic detonator, and more effectively ensures the safety and reliability of the product.

Description

technical field [0001] The invention relates to the technical field of electronic detonators, in particular to a method for testing the anti-shock wave performance of an electronic control module for electronic detonators. Background technique [0002] Industrial electronic detonator (referred to as electronic detonator) is an updated product of civil explosive equipment in my country. The safe and reliable performance of its electronic control module largely determines the reliability of electronic detonator ignition. Most domestic electronic detonator manufacturers adopt the cooperation form of electronic control module outsourcing, and the electronic control modules of different detonator manufacturers come from different electronic design companies, so there are inconsistent electronic control module circuit designs, large differences in device selection, inconsistent performance indicators, and product quality differences. Large, especially the lack of testing methods f...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F42C21/00

CPCF42C21/00

Inventor 杨文宋家良夏光张志刚何振岳彩新黄孟文赵晓莉高玉刚周晓红杨宗玲王傲秦婷黄嵩吴竞崔珍珍吴志超

Owner CHINA COAL TECH & ENG GRP HUAIBEIBLASTING TECHN RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com