Self-lubricating gear meshing transmission thermal analysis test bed

A test bench, self-lubricating technology, applied in the testing of mechanical parts, sensing radiation of moving objects, testing of machine/structural parts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

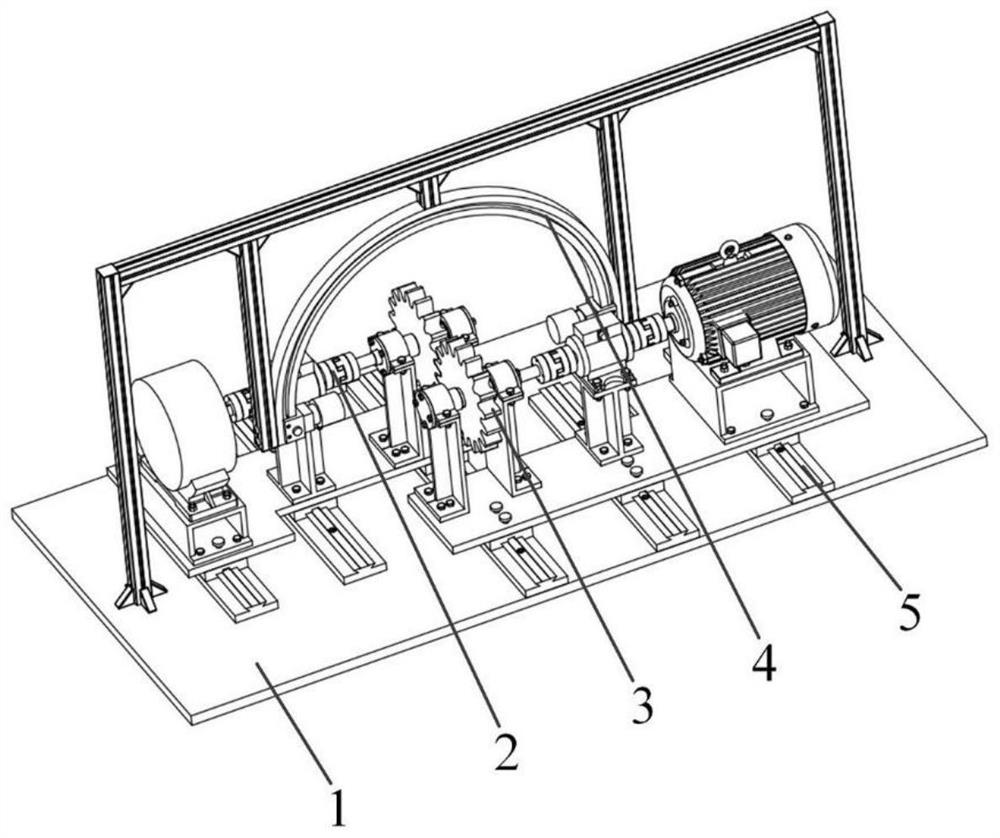

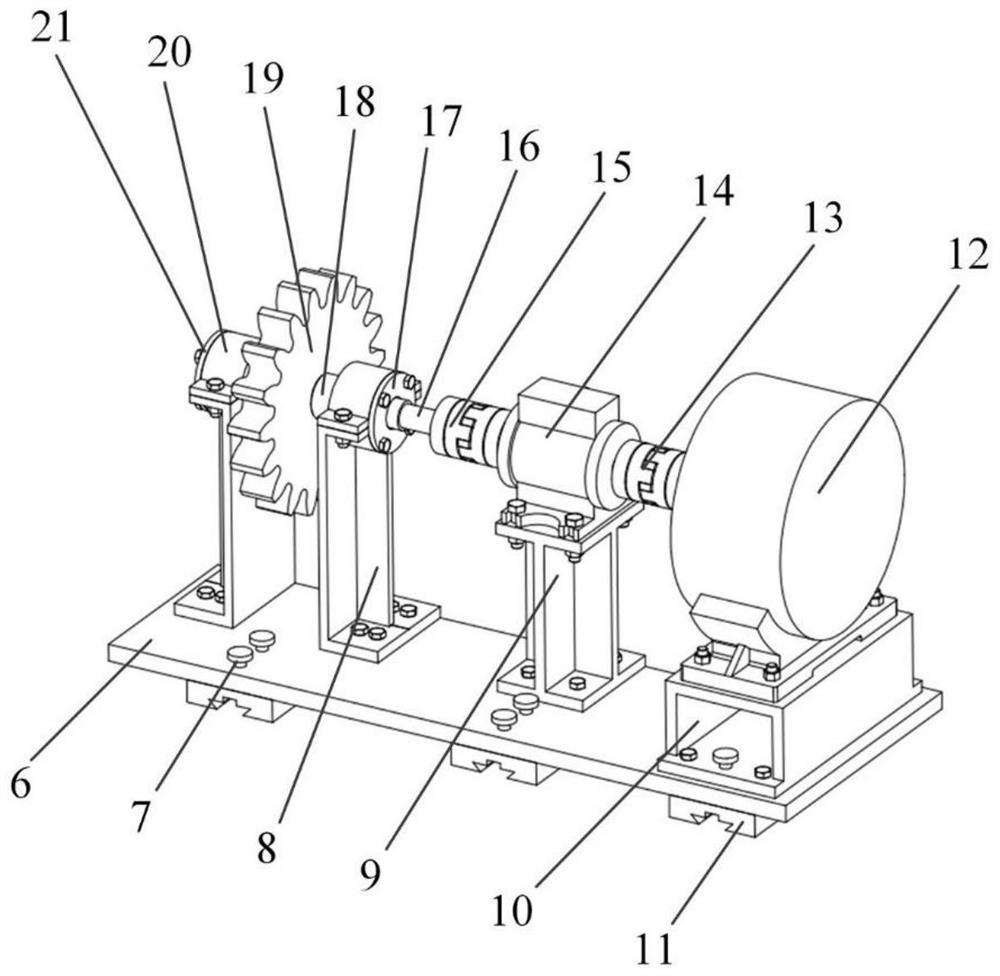

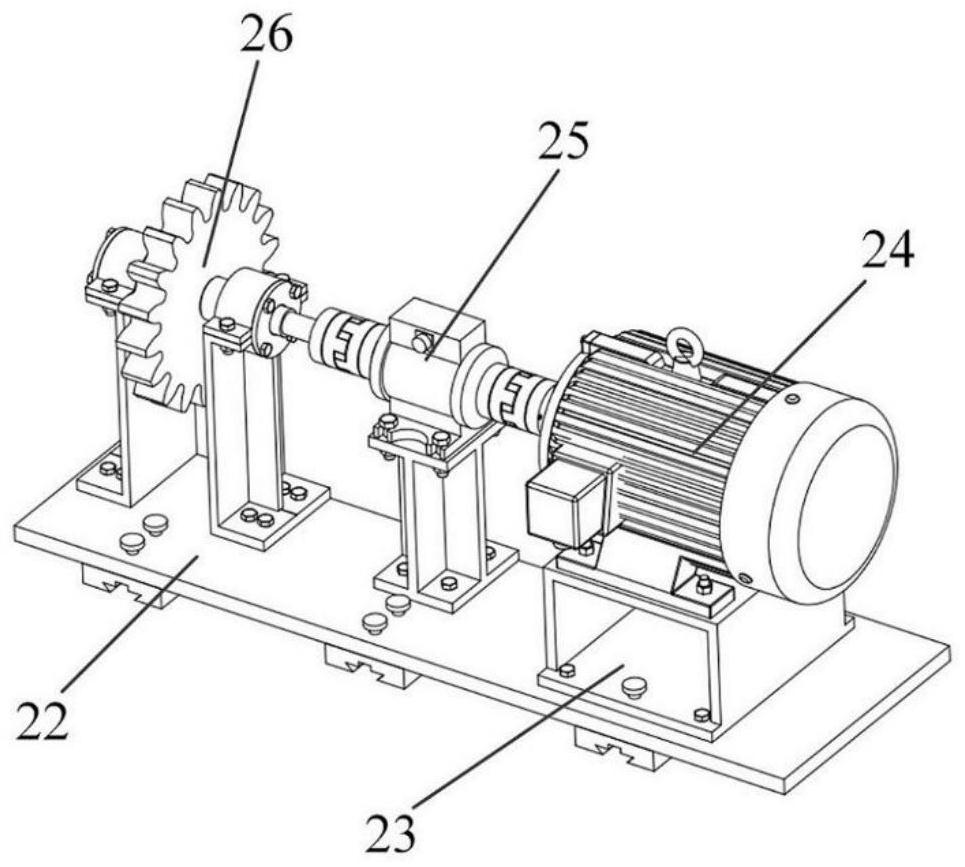

[0029] see figure 1 , the present embodiment is a preferred embodiment of the present invention, which provides a self-lubricating gear mesh transmission thermal analysis test bench, which includes a test bench bottom plate 1, a self-lubricating gear loading device 2, a self-lubricating gear driving device 3, an imaging Device 4, the lower guide rail 5 of the test bench; the lower guide rail 5 of the test bench is connected to the bottom plate 1 of the test bench by bolts; the upper guide rail of the test bench is installed under the self-lubricating gear load device 2 and the self-lubricating gear drive device 3 11, and is connected with the lower guide rail 5 of the test bench through the upper guide rail 11 of the test bench, which can translate and slide on the bottom plate of the test bench 1, and then move the self-lubricating gear load device 2 and the self-lubricating gear drive device 3 on the bottom plate of the test bench The self-lubricating driving gear 26 and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap