Ground thrust vector calibration device for small turbojet engine

A turbojet engine and thrust vectoring technology, which is applied in the field of wind tunnel tests, can solve the problems that the large-angle deflection of the tail nozzle cannot be realized, and the influence of the temperature of the exhaust flame of the turbine engine is not considered, so as to facilitate processing and assembly, reduce influence, and reduce transmission. hot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following description provides many different embodiments, or examples, for implementing various features of the invention. The elements and arrangements described in the following specific examples are only used to express the present invention in a concise manner, and are only used as examples rather than limiting the present invention.

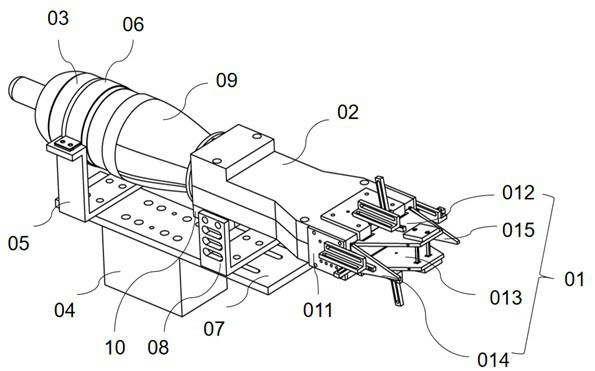

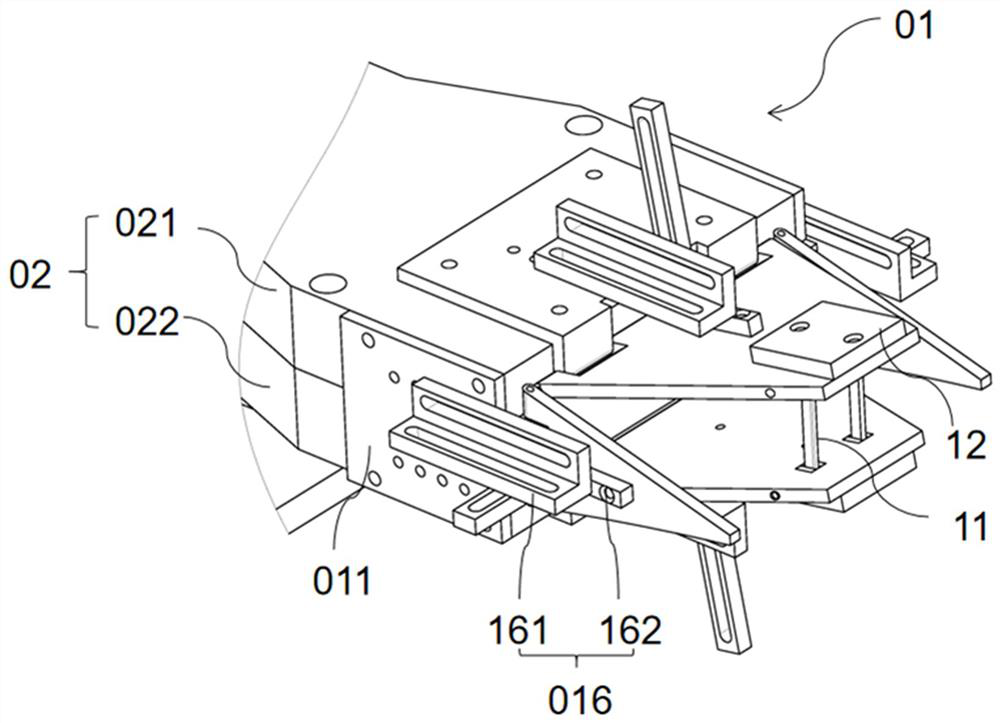

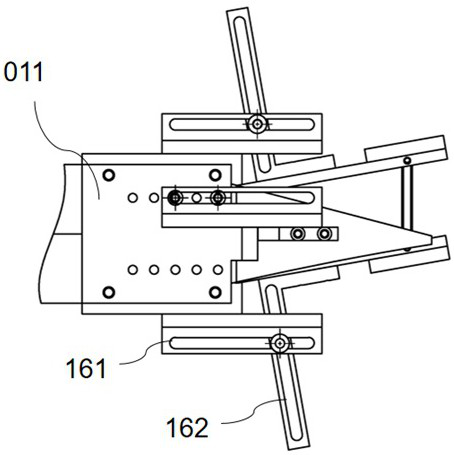

[0028] A small turbojet engine ground thrust vector calibration device, such as figure 1 and figure 2 As shown, it includes a deflector 01, and the deflector 01 includes a deflector and a deflector base 011; the deflector base 011 is fixed at the tail end of the nozzle diffuser section 02, the The deflector is rotatably connected to the deflector base 011 , and the rotation angle of the deflector is adjusted by rotating the positioning connector 016 .

[0029] Further, in this embodiment, the deflector includes an upper deflector 012, a lower deflector 013, a left deflector 014 and a right deflector 015; the deflector base 011...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com