Gas introduction device and substrate processing apparatus using same

A gas introduction device and gas introduction technology are applied in the fields of electrical components, gaseous chemical plating, semiconductor/solid-state device manufacturing, etc., which can solve the problems of decreased productivity, inability to ensure uniform thickness of film, long deposition time, etc., to ensure that the film Thickness uniformity, secure film deposition rate, effect of shortening feed time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

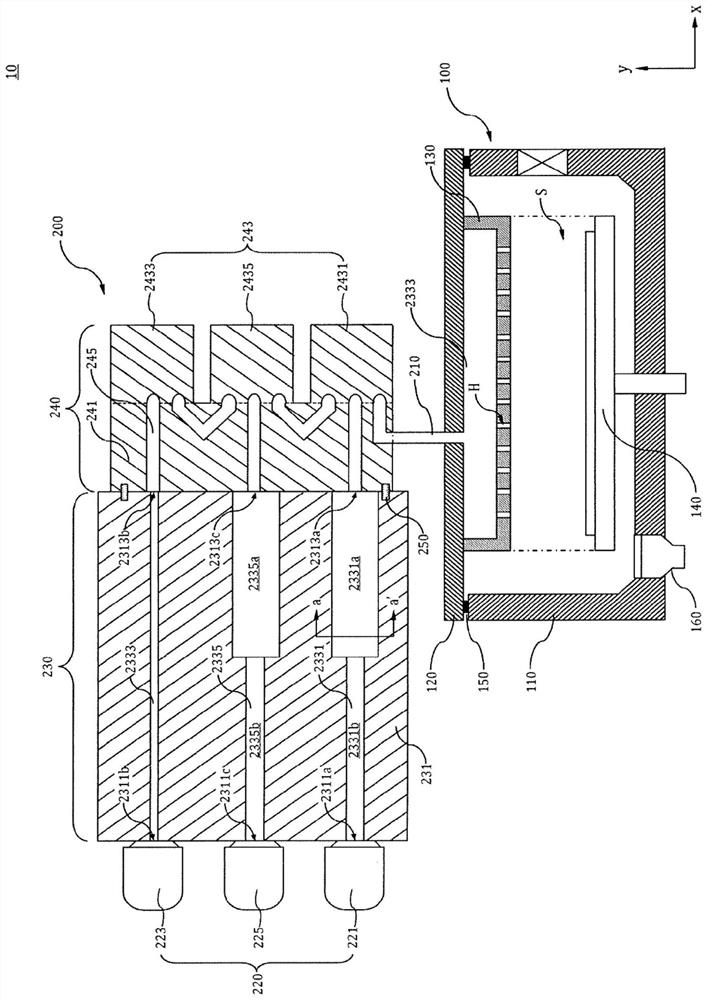

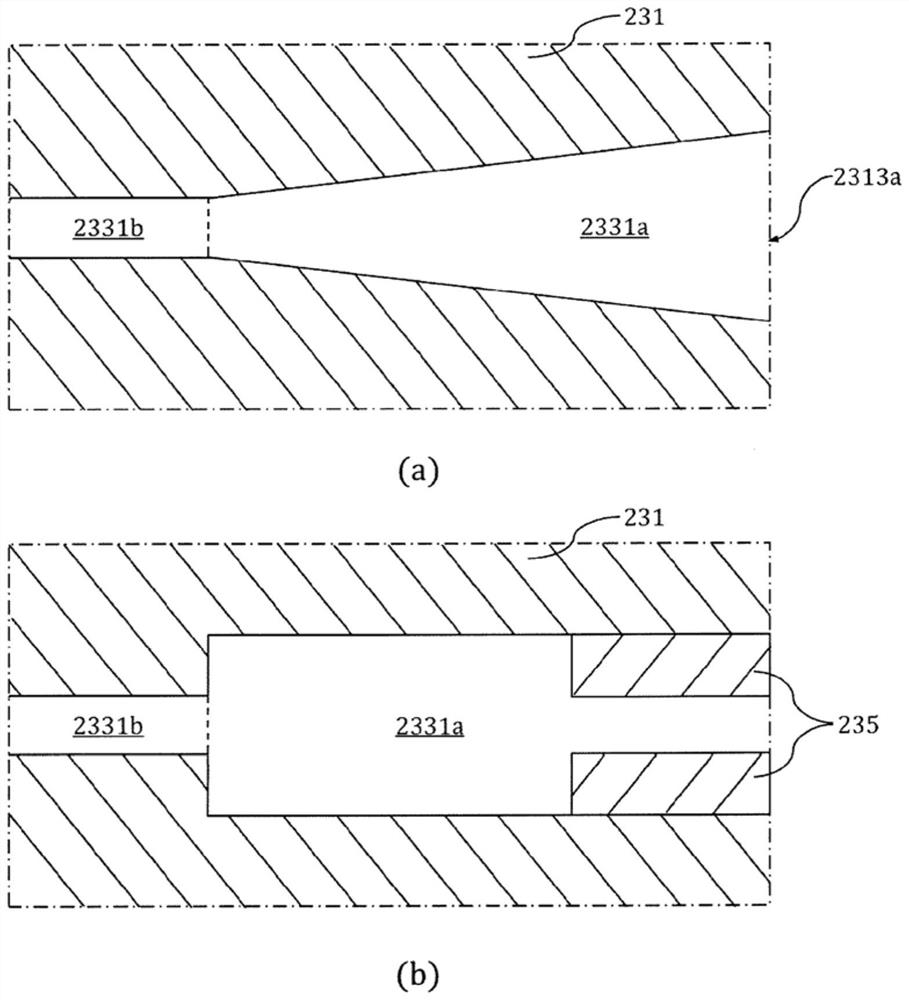

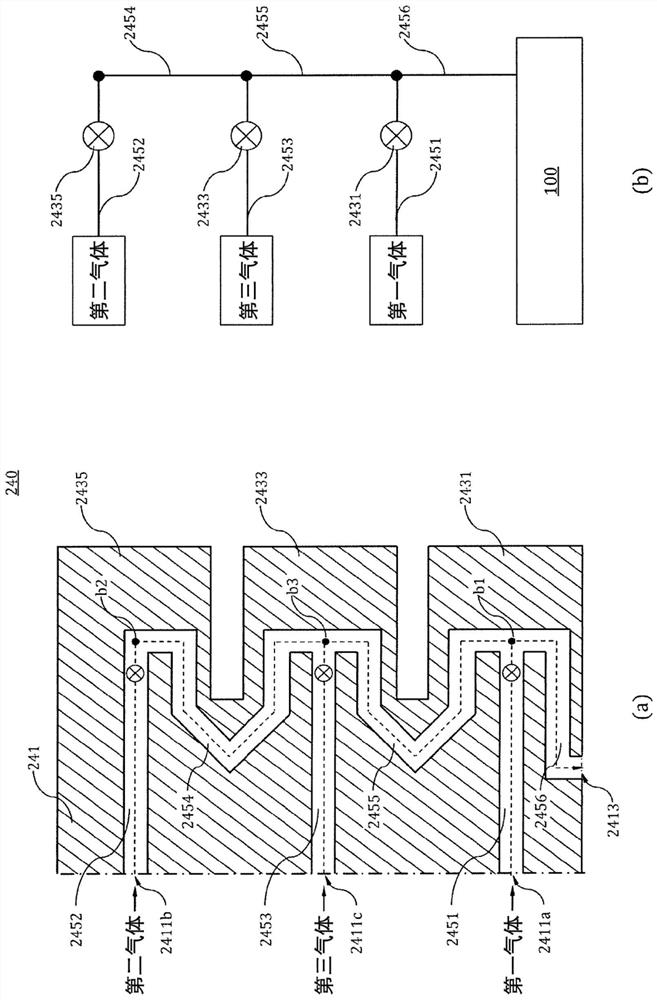

[0024] Embodiments that can specifically achieve the above objects will be described in detail below with reference to the accompanying drawings. These embodiments may be varied in various ways, and may have various forms. In connection therewith, specific embodiments are illustrated in the drawings and described in detail in the description.

[0025] It should be understood that although the terms "first", "second", etc. may be used herein to describe various elements, these elements should not be limited by these terms. It should also be understood that relative terms used below (such as "on" / "above" / "over" and "below" / "below" / "under") Can be construed as merely distinguishing one element from another without necessarily requiring or referring to some physical or logical relationship or order between the elements.

[0026] Terms used in the present disclosure are used to describe specific embodiments only, and do not limit the present disclosure. A singular expression in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com