Efficient compression system for realizing air separation

A compression system and air separation technology, applied in separation methods, cold treatment separation, and dispersed particle separation, etc., can solve the problems of reduced compression efficiency, large air intake resistance, and blockage of filter elements, and achieve the effect of improving compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

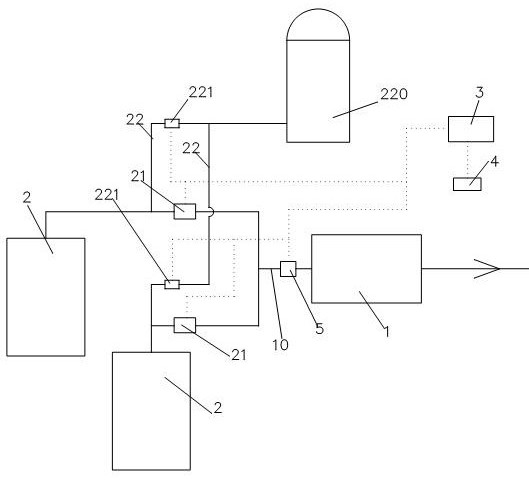

[0033] The invention provides a high-efficiency compression system for realizing air separation, referring to figure 1 , figure 2 , as a specific embodiment, the system includes a gas compressor 1, an air inlet 10 arranged at the air inlet of the gas compressor 1, at least two air filter devices 2 connected to the air inlet 10, A control valve 21 is provided between each of the air filter devices 2 and the air inlet, and also includes a control device 3, a humidity detection device 4 for detecting ambient humidity, and a micrometer arranged on the air inlet 10. Dust detection device 5 , the control device 3 is used to acquire the detection values of the humidity detection device 4 and the dust detection device 5 to control the opening and closing of the control valve 21 .

[0034]Specifically, for the convenience of description, two air filter devices 2 are provided here as an example. In this arrangement, when the compression system compresses the air, the control device ...

Embodiment 2

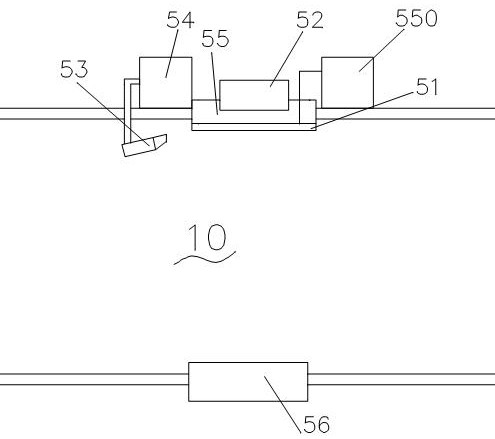

[0043] The present invention provides a high-efficiency compression system for realizing air separation, which is different from Embodiment 1 in that the air filtering device 2 is provided with a cleaning device, and the cleaning device includes a back-blowing branch 22, and the back-blowing One end of the branch is connected between the air filter device 2 and the corresponding control valve 21 , the other end is in communication with the high-pressure air source 220 , and each of the blowback branches 22 is provided with a solenoid valve 221 . refer to figure 1 , image 3 , by setting the back blowing branch to communicate with the high-pressure air source 220, when the air filter device 2 is used, the control device 4 controls the corresponding solenoid valve 221 to open, and the high-pressure air source enters along the air pipe 201 of the air filter device 2 for back blowing, Thereby, the fine dust attached to the filter element of the air filter device 2 is removed to a...

Embodiment 3

[0056] The present invention provides a high-efficiency compression system for realizing air separation, which is different from Embodiment 2 in that a plurality of connecting rods 245 are evenly spaced around the outer casing 241 on the outer side of the outer casing, and the cover body 242 is provided with a plurality of connecting parts 246 corresponding to the connecting rods one by one, and the connecting parts 246 are quickly detachably connected with the connecting rods 245 . Through the quick release connection, the cylindrical filter element can be replaced conveniently and quickly, avoiding the downtime of the compression system caused by the long time for replacing the filter element, and further ensuring the working efficiency of the compression system.

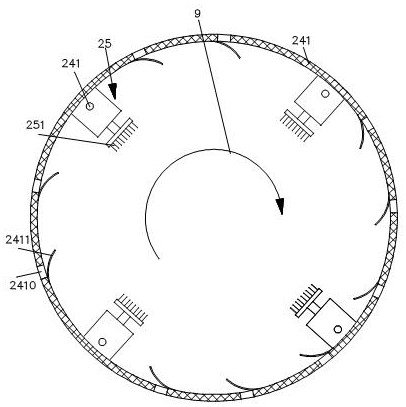

[0057] Further, refer to image 3 , Image 6 , Figure 7 , as a specific embodiment, the connection between the outer shell and the cover is as follows: the connecting part 246 includes a columnar member 2460 ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com