Natural enzyme soap containing fruit enzyme and production equipment of natural enzyme soap

A technology of natural enzymes and fruit enzymes, applied in mixers with rotary stirring devices, detergent compounding agents, transportation and packaging, etc. Improve the effect of blending effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

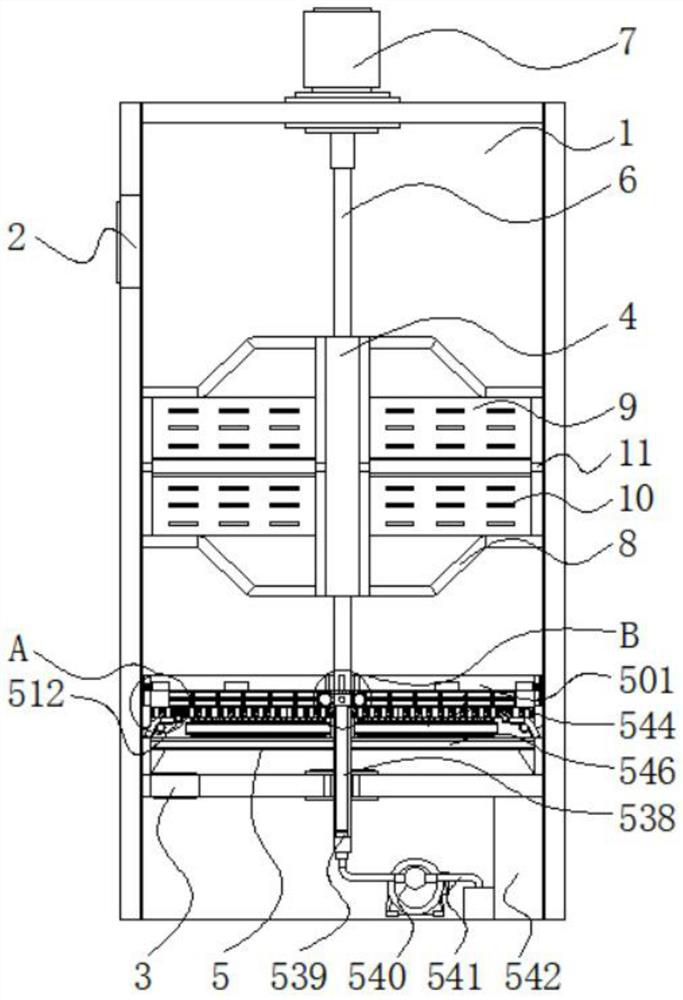

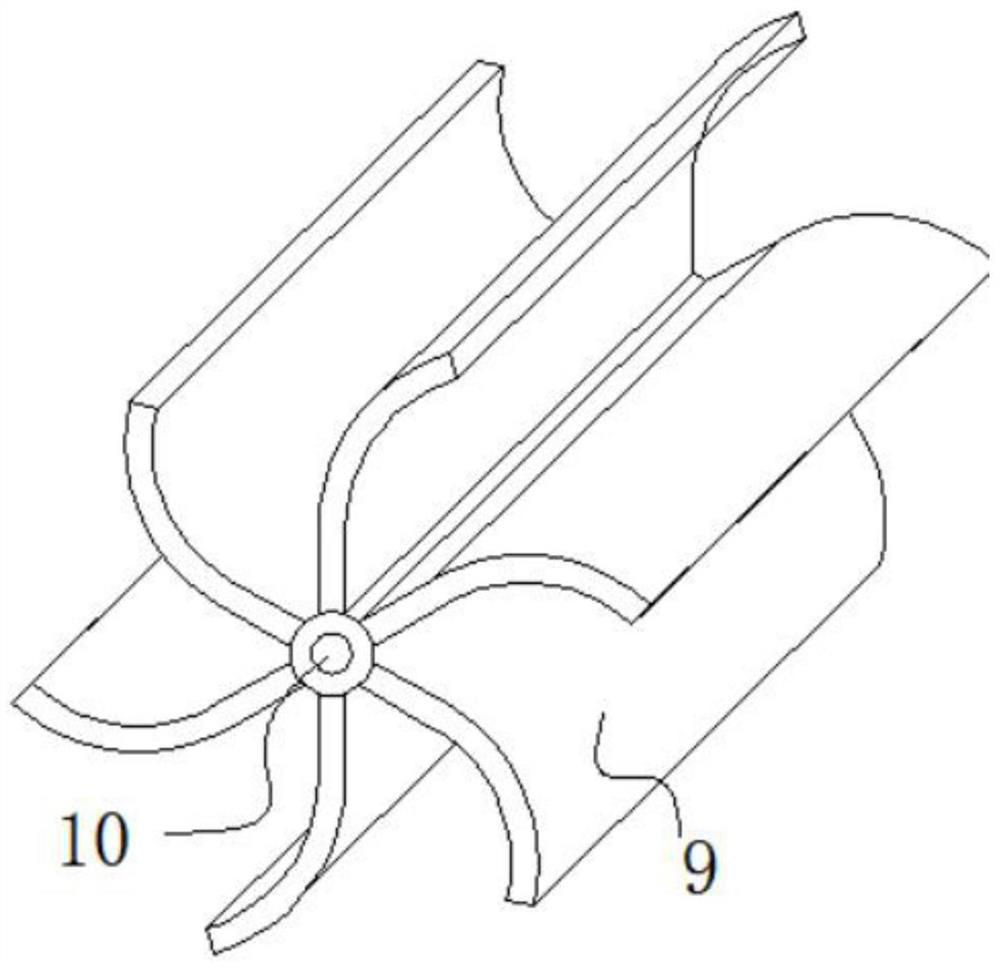

[0035] as attached figure 1 and figure 2 As shown, the present invention provides a kind of technical scheme: a kind of natural enzyme soap of fruit enzyme and production equipment thereof, comprise enzyme production tank body 1, and offer the feeding notch 2 and discharge groove on the enzyme production tank body 1 Port 3, the enzyme production tank body 1 is equipped with a fixed column sleeve 4 and an auxiliary filter mechanism 5, the fixed shaft rod 6 pierced through the fixed column sleeve 4 extends to the drive motor 7, and the drive motor 7 is fixed on the enzyme production tank body through threads 1, the fixed post sleeve 4 is provided with several ring-shaped fixed frames 8, the fixed frame 8 is provided with a horizontal sleeve, and the horizontal sleeve is provided with several arc-shaped blades 9, each blade 9 There are several elongated leaf holes 10, both ends of the horizontal shaft 11 passing through the horizontal sleeve extend to the inner wall of the fixe...

Embodiment 2

[0037] The solution in Embodiment 1 will be further introduced in combination with specific working methods below, see the following description for details:

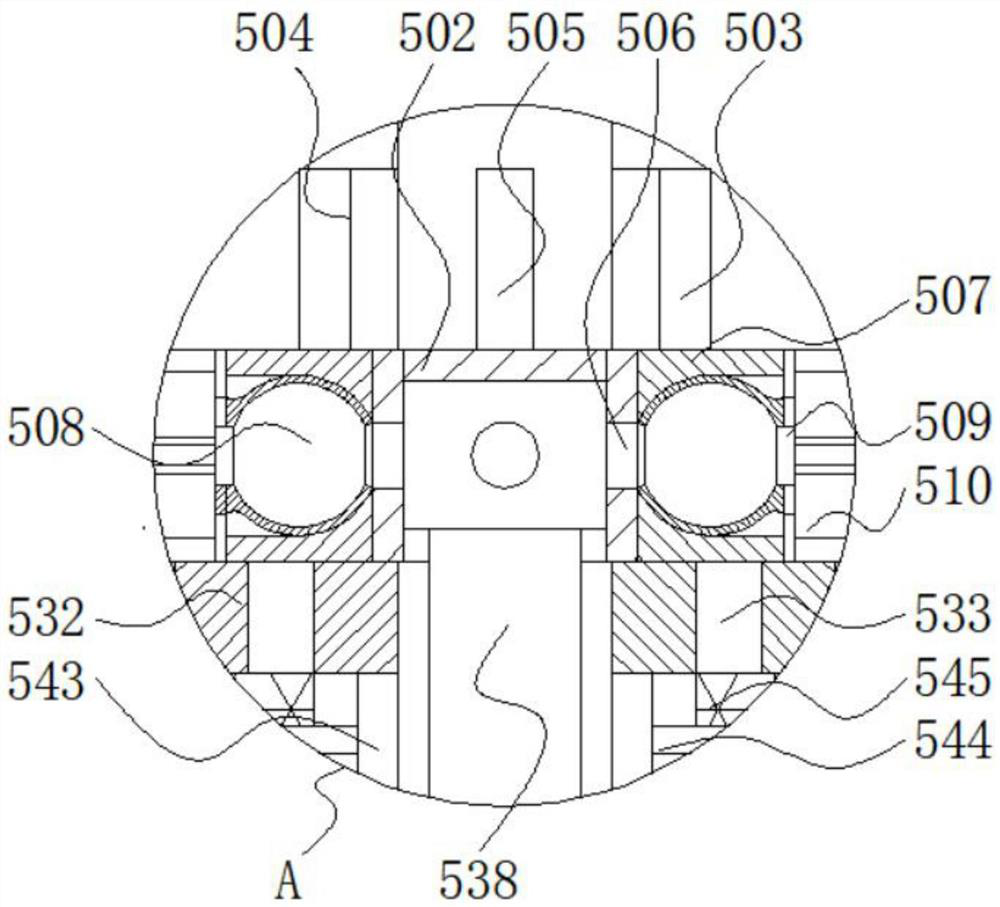

[0038] Such as figure 1 and image 3 As shown, as a preferred embodiment, on the basis of the above method, further, the auxiliary filter mechanism 5 includes a cylinder 501, a fixed turntable 502, a fixed groove column 503, a limit groove 504 and a fixed plug 505, the cylinder 501 is provided with a fixed turntable 502, and the fixed turntable 502 is provided with a fixed groove column 503 integrally fixed with the fixed turntable 502. The fixed groove column 503 is provided with several limit grooves 504, and the limit groove 504 is provided with A number of fixed plugs 505 corresponding to the limit grooves 504 and matching in size, the fixed plugs 505 are welded and fixed on the fixed shaft 6, and the fixed shaft 6 can embed the fixed plugs 505 in the limit grooves 504 Inside, the fixed shaft 6 can be connected wi...

Embodiment 3

[0046] The schemes in Embodiment 1 and Embodiment 2 are further introduced in conjunction with specific working methods below, see the following description for details:

[0047] A kind of natural enzyme soap of fruit enzyme, the natural enzyme soap comprises the following raw materials in mass percentage: 30-60% of Sapindus ferment, 10-17.5% of lemon, 10-17.5% of grapefruit, 10-17.5% of orange, 10% of sweet orange -17.5%.

[0048] Specifically, a natural enzyme soap of fruit enzymes, the natural enzyme soap comprises the following raw materials in mass percentage: 60% of Sapinberry enzyme, 10% of lemon, 10% of grapefruit, 10% of orange, and 10% of sweet orange.

[0049] To sum up, when using the natural enzyme soap of this fruit enzyme and its production equipment, first, the fixed shaft 6 can embed the fixed plug 505 inside the limit groove 504, and the fixed shaft 6 can pass through the limit groove. The cooperation between the groove 504 and the fixed plug 505 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com