Compression type evanescent mode and pouring method for evanescent mode casting

A technology of lost foam and compaction table, which is applied to casting molding equipment, cores, casting molds, etc. It can solve the problems of no smoothing device, reduce the efficiency of dry sand vibration molding, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

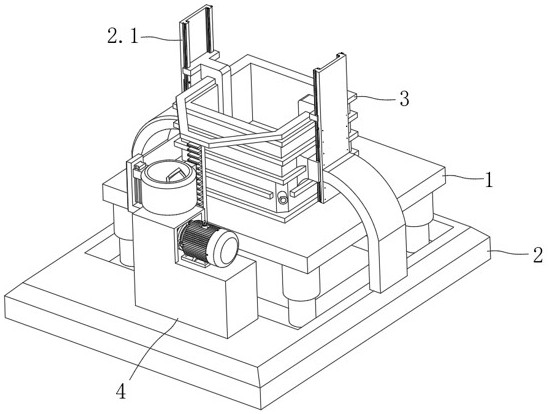

[0035] see Figure 1-12 , the pouring method for compacted lost foam and lost foam casting is used to solve the problem that in the process of filling dry sand into the sand box, because there is no smoothing device, the staff need to repeatedly put dry sand in the sand filling process. The sand in the box is smoothed out, which leads to a problem that reduces the efficiency of dry sand vibratory molding.

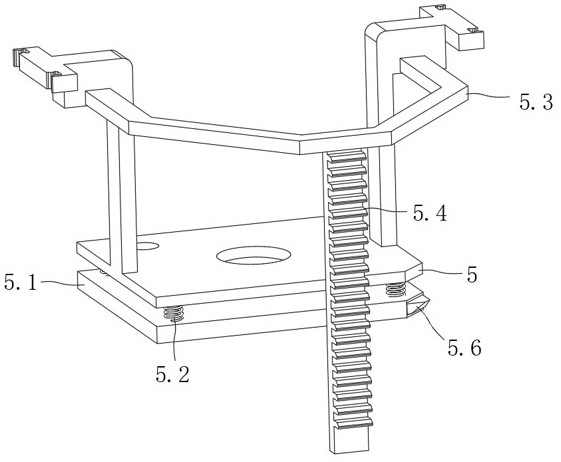

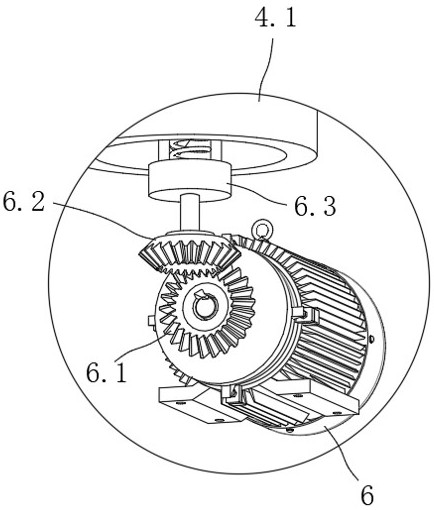

[0036] In the technical scheme further proposed as the present invention, it includes a vibrating table body 1 and a mold 3 arranged on the vibrating table body 1. Vibration molding, in the process of vibration, reduces the gap between the molding sand and increases the bulk density of the molding sand. After the sand filling is completed, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com