Efficient cleaning type sand mold transfer device

A transfer device, sand mold technology, applied in the direction of transporting molds, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient cleaning, sand falling off, etc., to reduce friction, ensure stability, and avoid slight vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to illustrate the technical features of the solution more clearly, the solution will be described below through specific implementation modes.

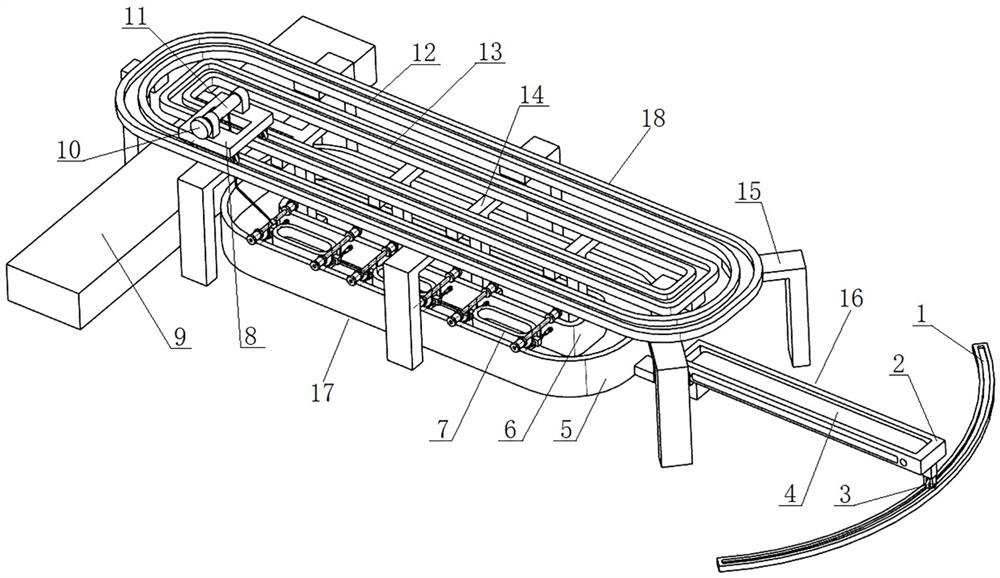

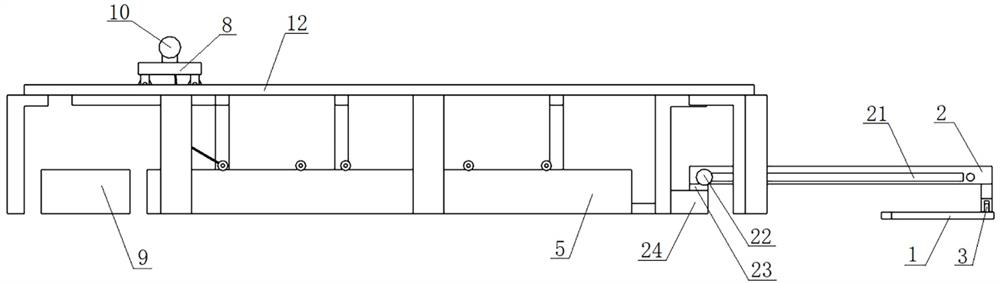

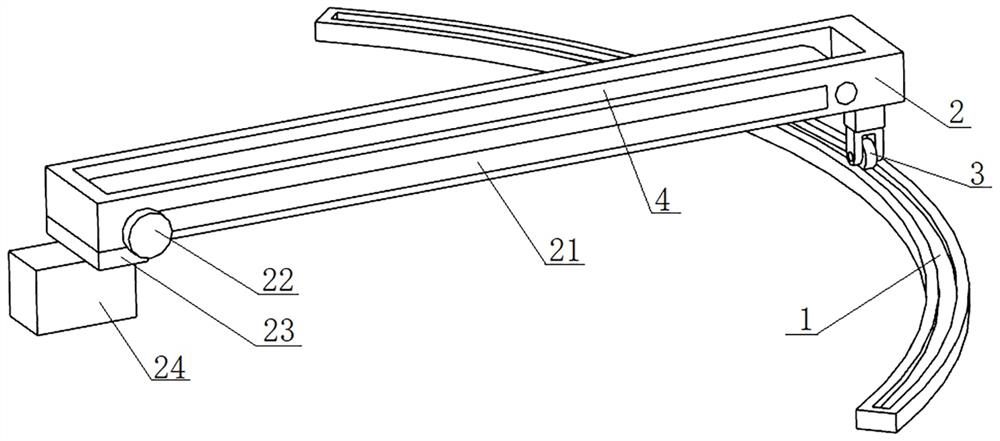

[0045] see figure 1 with figure 2, an efficient and clean sand mold transfer device, comprising a transfer structure one 16 arranged in the sand mold production area, a transfer structure two 17 arranged between the sand mold production area and the pouring production area 9, and a rail arranged above the transfer structure two 17 The transmission system 18 and the rail transmission system 18 are provided with a power car 83, and the second transfer structure 17 is a runway-shaped annular pool, and a shipping structure 19 is arranged in the annular pool, and the shipping structure 19 and the power car 83 are detachably connected.

[0046] see Figure 4 , the transfer structure 2 17 includes the lower outer ring track 5, the lower inner ring track 6 arranged inside the lower outer ring track 5, the substrate closed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com