Industrial product quality evaluation and prediction system

A quality evaluation and prediction system technology, applied in data processing applications, instruments, calculations, etc., can solve problems such as increased work intensity of staff, dumping of workpieces, complex device structures, etc., to improve detection and evaluation efficiency, push and whereabouts are convenient, Effect of Improving Evaluation Efficiency

Pending Publication Date: 2022-05-13

林丽萍

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Some existing industrial product quality assessment and prediction systems cannot automatically perform multi-directional rotation detection when inspecting industrial products, and require staff to manually turn over, thereby increasing the work intensity of the staff and reducing the overall device quality. At the same time, some quality evaluation systems that can automatically flip workpieces cannot perform assembly line operations, or when performing assembly line operations, the workpieces are turned over through multi-level transmission, which makes the structure of the entire device more complicated. The maintenance efficiency of the whole device is not good. At the same time, when the multi-level transmission is turned over, the workpiece is prone to dumping, which affects the processing progress of the whole device.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0032] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

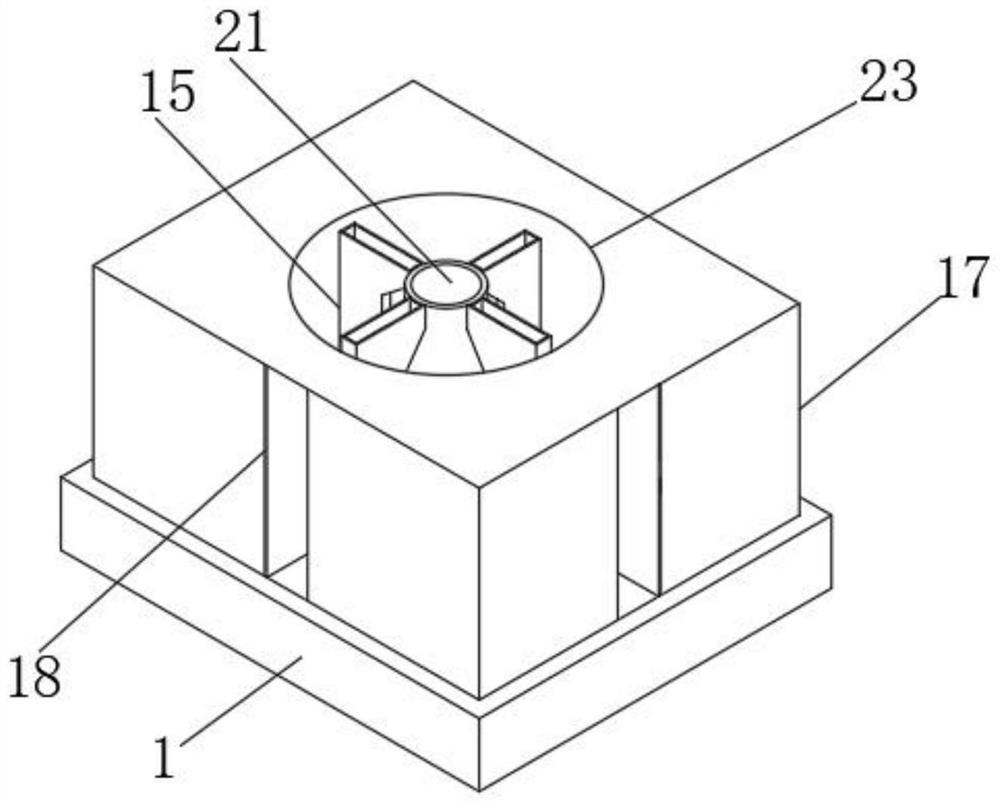

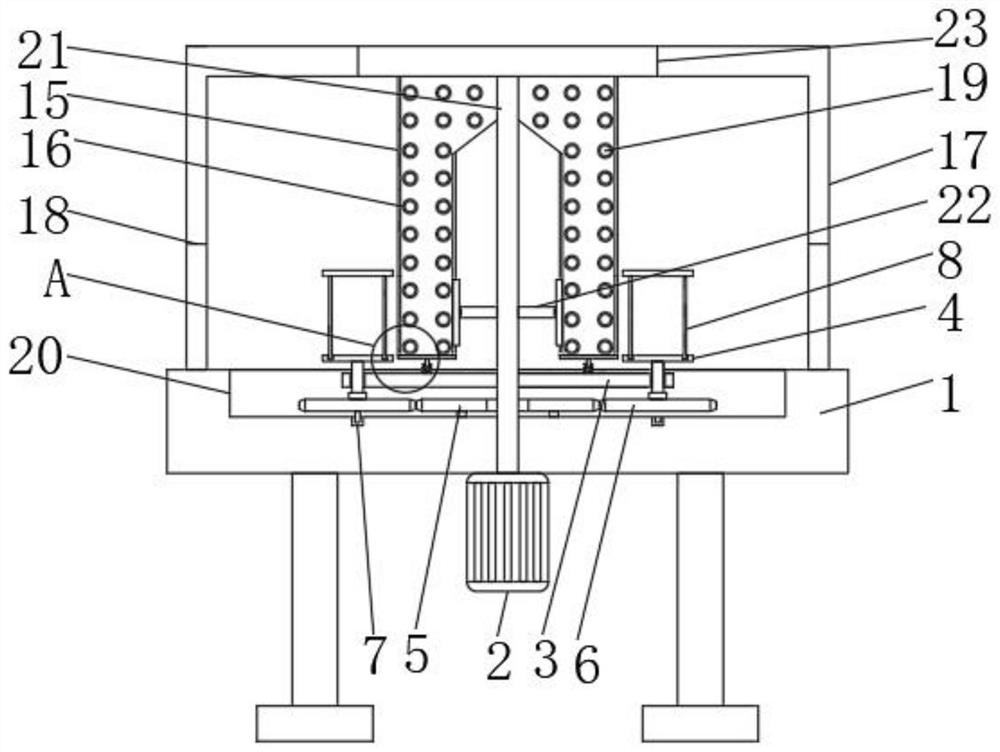

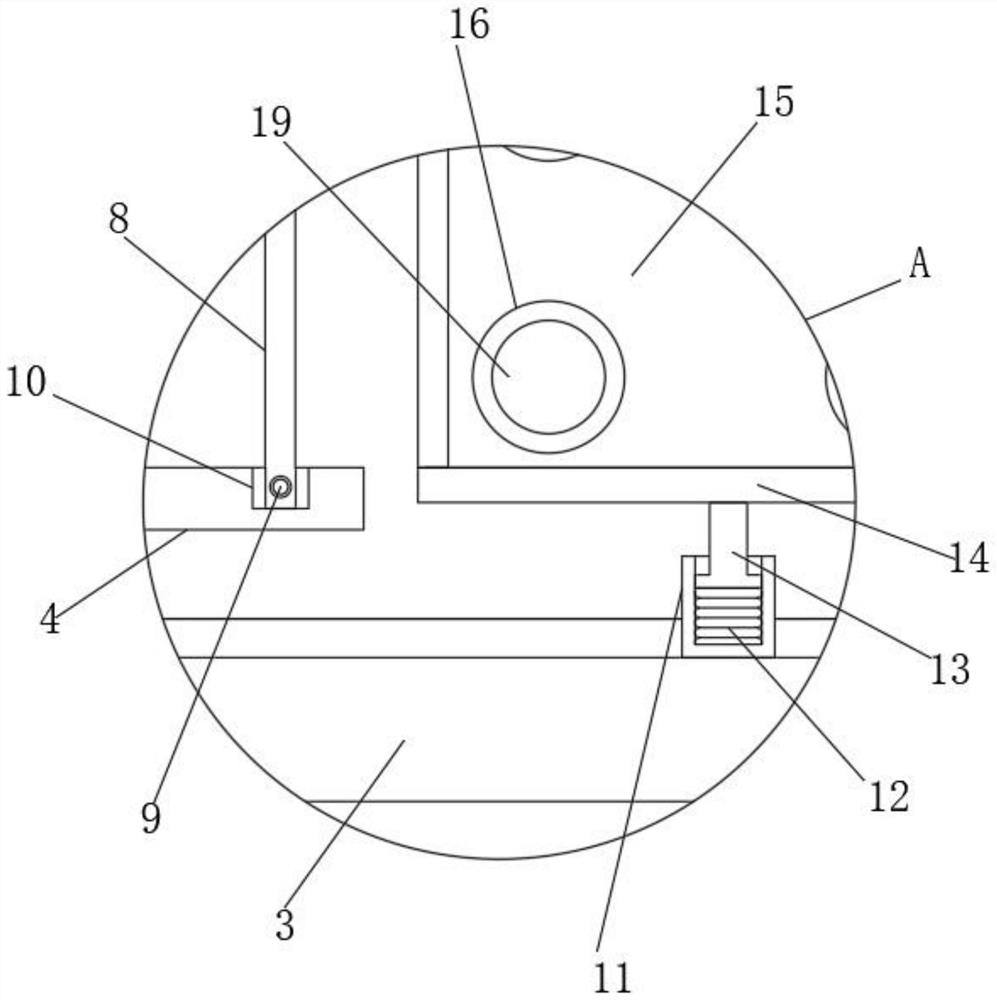

The invention belongs to the technical field of industrial products, and particularly relates to an industrial product quality evaluation and prediction system which comprises a machining platform, a servo motor is fixedly connected to the lower surface of the machining platform through bolts, and a connecting rod is fixedly connected to the output end of the servo motor through bolts. A detection frame is fixedly connected to the upper surface of the machining platform through bolts, a bearing table is fixedly connected to the outer surface of a connecting rod through bolts, a storage frame is arranged on the upper surface of the machining platform, and a driving gear is fixedly connected to the interior of the storage frame through bolts. At the same time, some quality evaluation systems capable of automatically overturning workpieces cannot carry out assembly line work, or when the assembly line work is carried out, overturning work of the workpieces is achieved through multi-layer transmission, so that the overhaul efficiency of the whole device is poor, and meanwhile when overturning is carried out through multi-layer transmission, the workpieces are prone to toppling over.

Description

technical field [0001] The invention relates to the field of industrial products, in particular to a system for evaluating and predicting the quality of industrial products. Background technique [0002] Industrial production and life can bring convenience to our life. By assembling and processing industrial products, people can be more efficient in their daily life. In order to ensure that people can use it normally and reduce the occurrence of defective products , after the production of industrial products, sampling inspection is required, and the quality of industrial products is evaluated through the detection of detection devices. However, there are some problems in the use of conventional industrial product quality evaluation and prediction systems, such as; [0003] Some existing industrial product quality assessment and prediction systems cannot automatically perform multi-directional rotation detection when inspecting industrial products, and require staff to manua...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65G47/248B65G47/82G06Q10/06

CPCB65G47/248B65G47/82G06Q10/06395

Inventor 林丽萍

Owner 林丽萍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com