Production method of high-quality acid pickling strip steel

A production method and high-quality technology, applied in the field of strip steel pickling, can solve problems such as blackboard surface, incomplete removal of iron sheet, rust, etc., and achieve the effects of reducing under-pickling, shortening pickling time, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

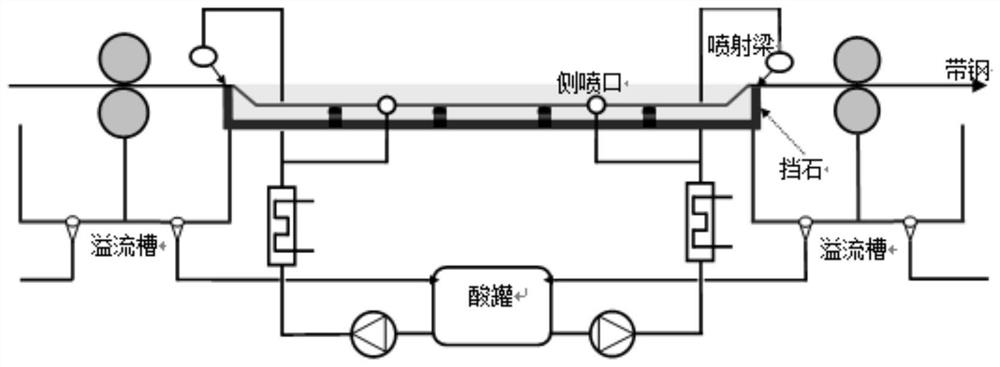

[0049] A kind of production method of high-quality pickled steel strip, strip steel width 1320mm, specifically comprises the following steps:

[0050] 1. After coiling, the steel coil is naturally cooled to 45°C.

[0051] 2. Control the temperature of the pickling solution in the pickling process to 80°C.

[0052] 3. The strip steel speed in the pickling process section is 160m / min; in case of an accident, stop the process; the reddish-brown or carbon-black strip steel produced during the shutdown process will be removed as waste.

[0053] 4. The clamping pressure of the cylinders at both ends of the squeezing roller is 0.28Mpa; reduce the elastic deformation of the squeezing roller; reduce the amount of acid liquid brought out by the squeezing roller;

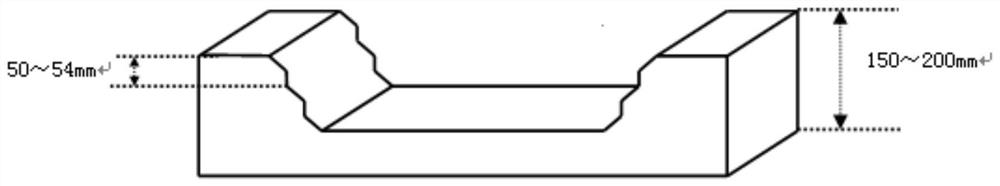

[0054] 5. It is required that the wear depth of the stretch straightening roller is ≤5mm, and the roller should be replaced when the wear depth of the stretch straightening roller exceeds 5mm;

[0055] When the stretching an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com