Liquid pumping, adding and metering system for raw materials of pavement mixture

A metering system and raw material technology, which is applied in the field of liquid pumping and adding metering system, can solve the problems such as the abnormal operation of the pouring equipment, and achieve the effect of being easy to control and not easy to pour back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

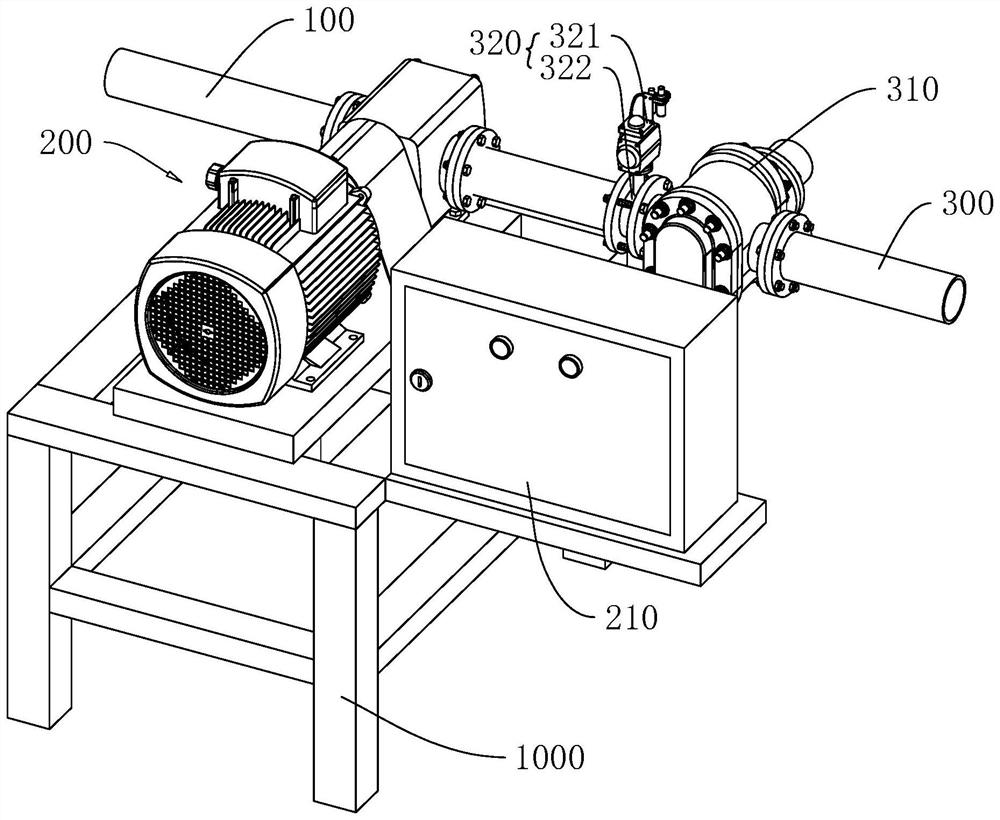

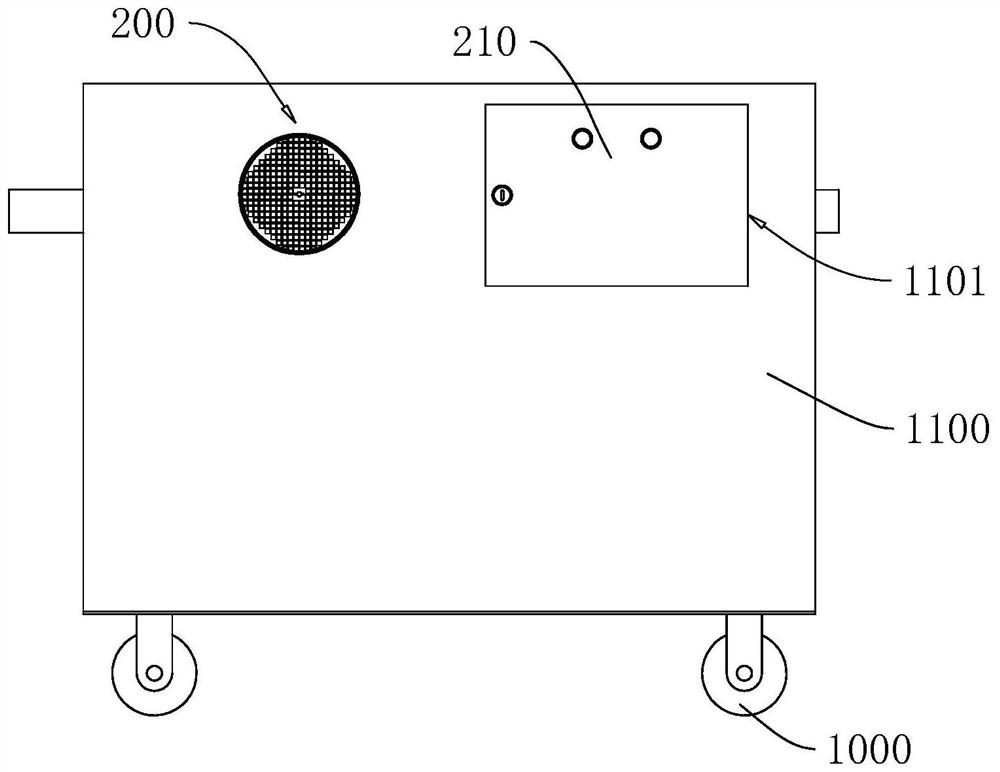

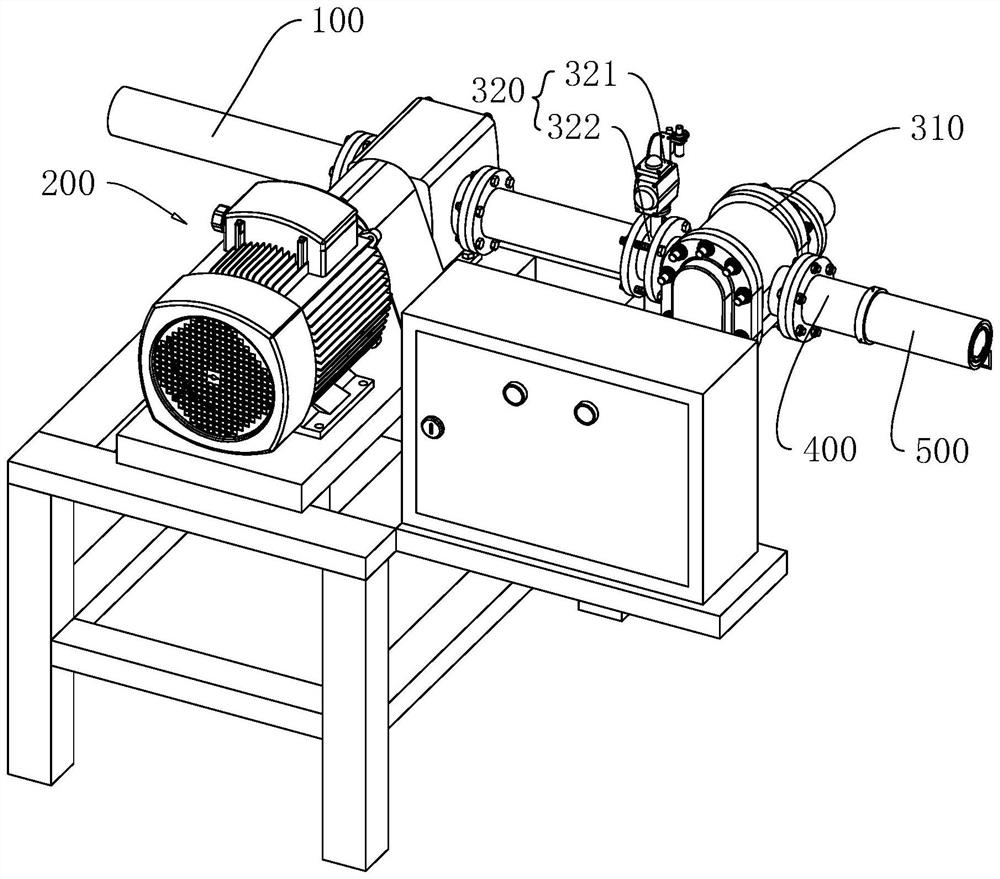

[0039] refer to figure 1 , The pumping addition metering system includes a feed pipe 100 , a pump body 200 , a regulating valve 320 and a discharge pipe 300 connected in sequence along the flow direction of raw materials. Connect the feed pipe 100 with the container containing the raw materials, and the end of the discharge pipe 300 away from the pump body 200 is connected with the mixer, open the regulating valve 320, and start the pump body 200, so that the pump body 200 pumps the liquid raw materials into the mixing machine inside the plane.

[0040] In order to make the pumping and adding metering system stop running, the regulating valve 320 can be closed in time, so that the material in the discharge pipe 300 is not easy to be poured back, so the regulating valve 320 includes a valve body 322 and a controller 321, and the controller 321 and the valve body 322 to control the opening and closing of the valve body 322, the controller 321 is electrically connected to the pu...

Embodiment 2

[0048] When the operation of the pumping and adding metering system is finished and the staff cleans the pumping and adding metering system with cleaning agent, it is easy to appear that the side wall of the discharge pipe 300 away from the pump body 200 is not easy to be cleaned, resulting in the occurrence of the inner wall of the discharge pipe 300. The situation of partly bonding materials, so for this kind of situation, the difference between this embodiment and embodiment one is: refer to image 3 and Figure 4 , The discharge pipe 300 includes a connecting sub-pipe 400 , a connecting sub-pipe 500 and a sliding sub-pipe 600 , one end of the connecting sub-pipe 400 communicates with the flow meter 310 , and the other end communicates with the connecting sub-pipe 500 . The sliding sub-tube 600 is located inside the connecting sub-tube 500, and there are multiple support rods 610 connected to the sliding sub-tube 600. The tubes 600 are distributed uniformly in the axial di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com