Method for controlling oil film thickness of static pressure rotating table to be constant under eccentric load

A technology of rotary table and oil film thickness, which is applied in the direction of engine lubrication, bearings, shafts and bearings, etc., can solve the problems of uneven oil film thickness and reduced machining accuracy of static pressure rotary table, and achieve the solution of uneven oil film thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

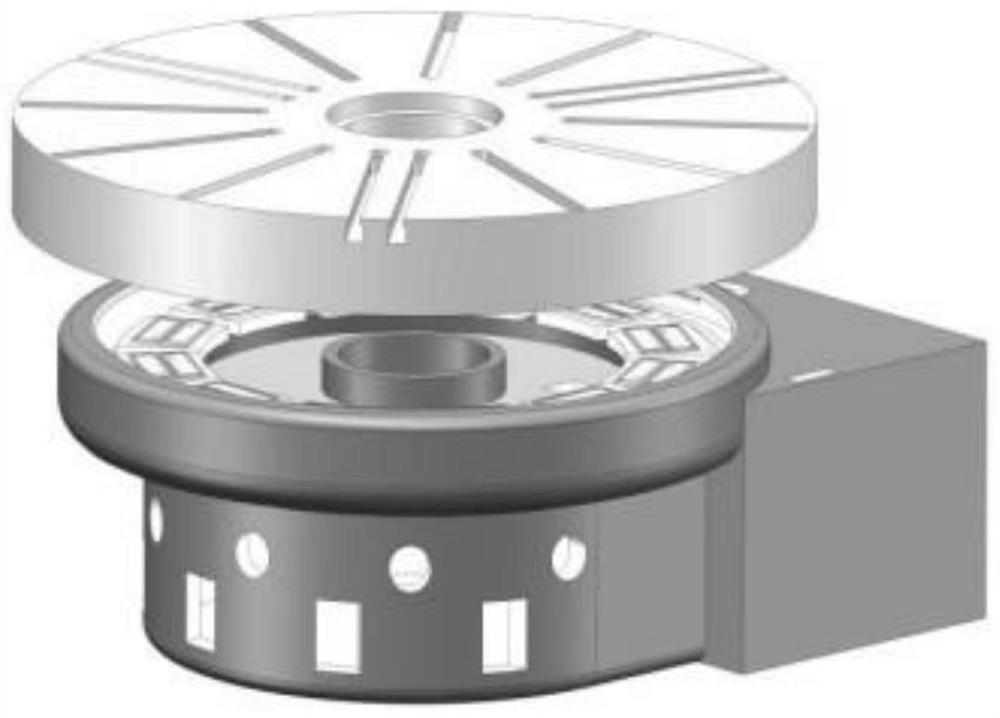

[0014] The present invention starts from the macro-regulation and micro-regulation two aspects, the design of three-channel regional oil film control scheme, the static pressure rotary table to implement a three-aliquot regional division, static pressure rotary table such as Figure 1 as shown.

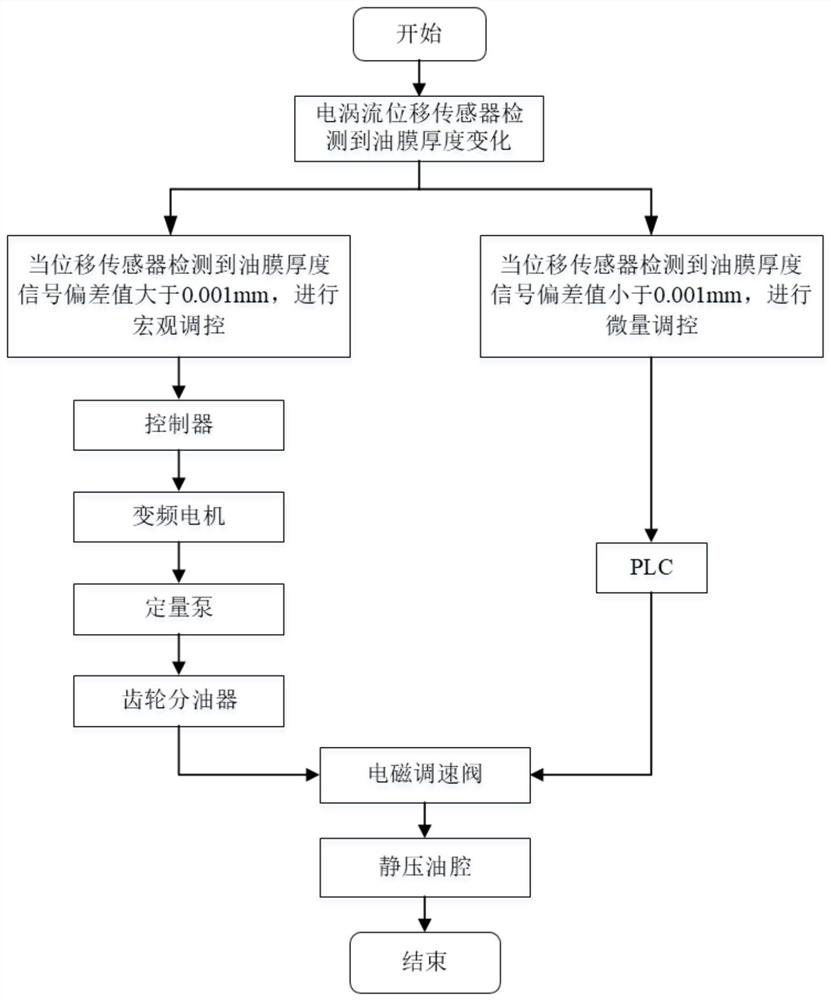

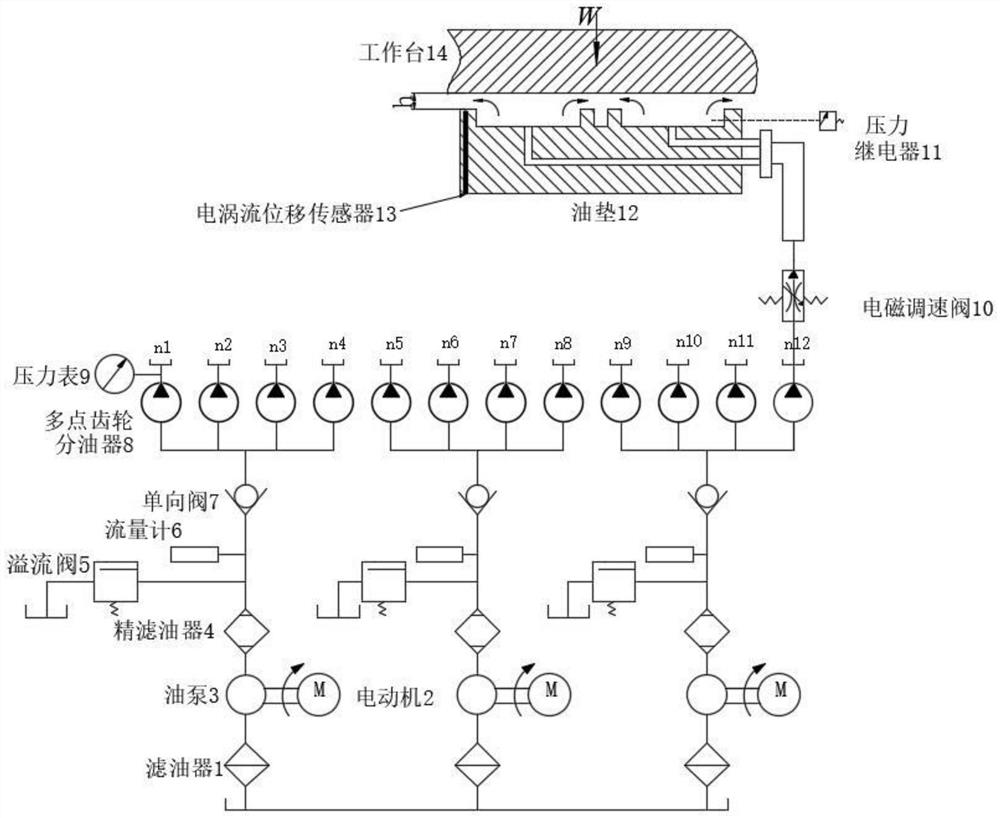

[0015] Each motor controls an area of the oil chamber, and between each gear separator and the oil chamber of the static pressure oil pad is provided with an electromagnetic speed control valve, when the static pressure rotary table is affected by eccentric load, the oil film is monitored in real time by the eddy current displacement sensor, when the eddy current sensor detects that the oil film thickness and the given value deviation is greater than 0.001mm, the signal is fed back to the controller, and the motor is regulated by the controller, thereby changing the speed of the quantitative pump and realizing the macro regulation of the oil film thickness control.

[0016] When the eddy-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com