Dyeing and drying equipment for textiles and use method

A drying equipment and textile technology, which is applied in the field of textile printing and dyeing, can solve problems such as breakage, textile tension changes, and textile wrinkles, and achieve the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

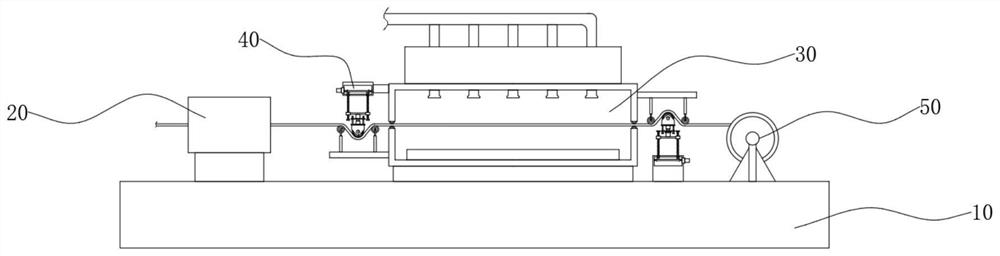

[0044] A dyeing and drying equipment for textiles, comprising a drying table 10, a microwave dryer 30 and a feeding roller 50 are installed on the top of the drying table 10, and self-adjusting tension assemblies 40 are installed on both sides of the microwave dryer 30;

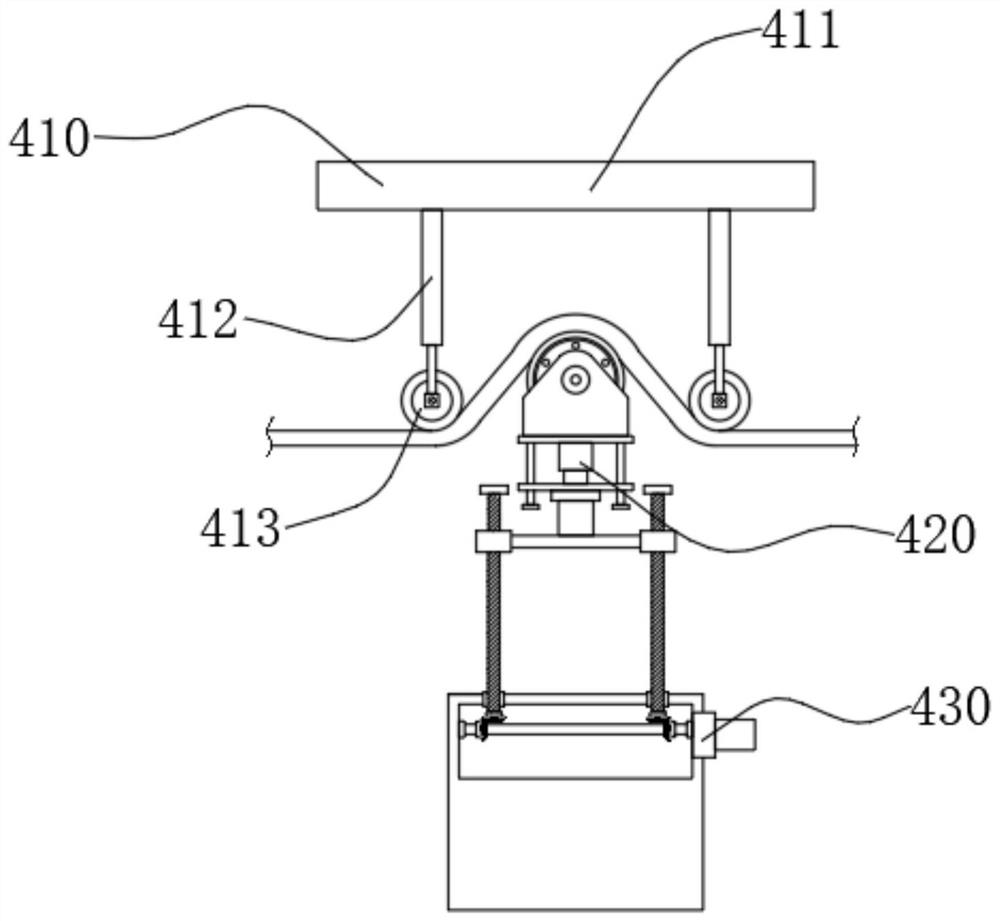

[0045]The self-adjusting tensioning assembly 40 includes an upper tensioning member 410, a lower tensioning member 420 arranged up and down opposite to the upper tensioning member 410, and a driving part 430 for driving the lower tensioning member 420 up and down, the upper tensioning member 410 and the lower tensioning member 410 The tensioning parts 420 are all installed on the outer wall of the microwave dryer 30, and one end of the upper tensioning part 410 and the lower tensioning part 420 respectively abut against the upper and lower end faces of the textile, and the driving part 430 is connected with the lower tensioning part 420, The upper tension member 410 includes a support frame 411, the bottom of ...

Embodiment 2

[0050] On the basis of Example 1, the function of preliminary dehydration is added.

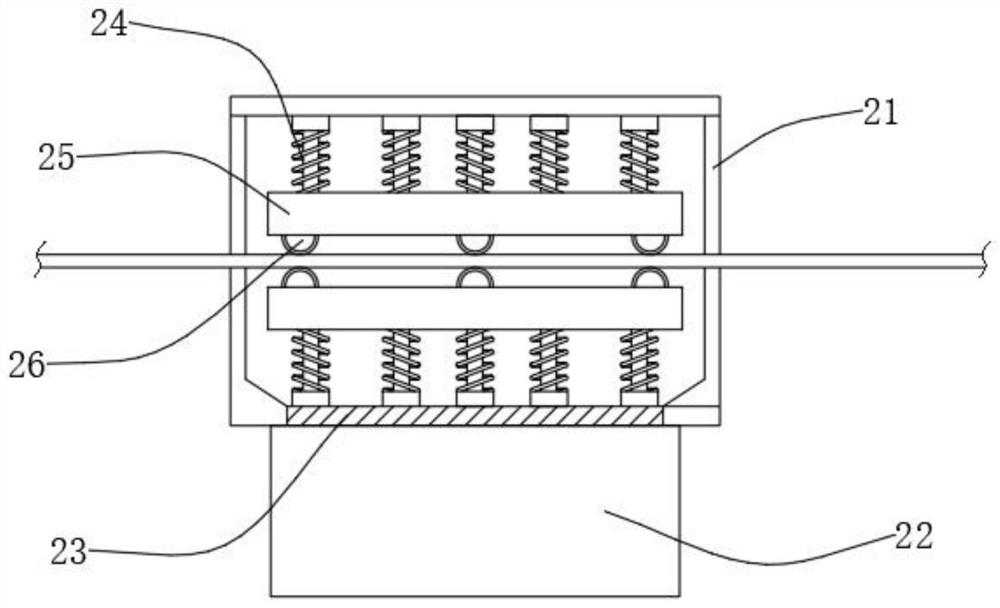

[0051] The water squeezing assembly 20 includes a water squeezing table 21, the bottom of the water squeezing table 21 is fixedly connected with a water collecting tank 22, and the top of the water collecting tank 22 is provided with multiple rows of permeable grooves 23, and the inside of the water squeezing table 21 is symmetrically arranged with spring columns 24, One end of the spring column 24 is fixedly connected with a squeeze seat 25, and one side of the squeeze seat 25 is rotatably connected with a squeeze wheel 26, and the outer wall of the squeeze wheel 26 is provided with an elastic rubber washer.

[0052] refer to Figure 1-6 , before the textiles enter the microwave dryer 30, first, through the water squeezing assembly 20, when the textiles enter the water squeezing table 21, because the spring column 24 exerts pressure on the water squeezing seat 25, the textile is squeezed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com