Single-phase autotransformer wire end alternating current induction voltage withstanding test method

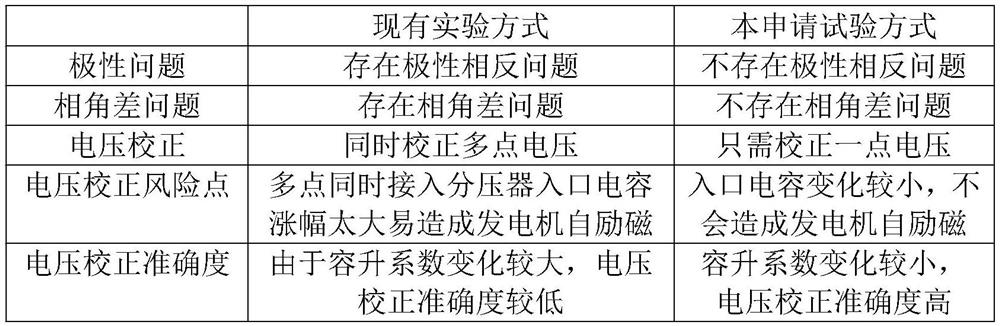

A technology of autotransformer and withstand voltage test, applied in the direction of testing dielectric strength, etc., can solve the problems of increasing the risk of generator self-excitation, large voltage correction deviation, and inter-turn insulation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

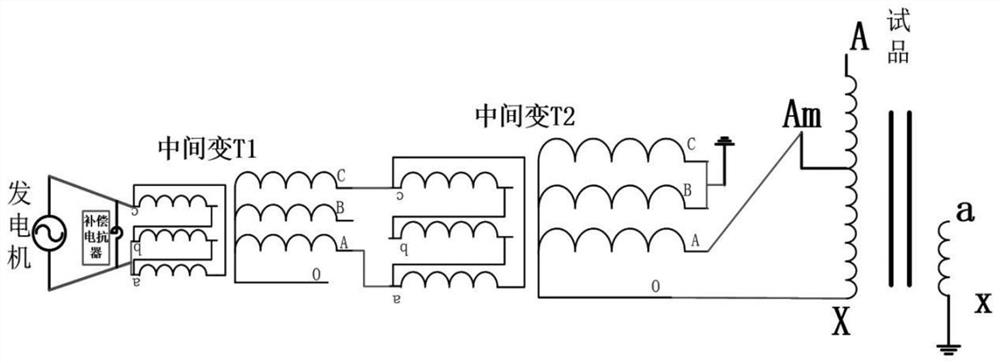

[0014] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are part of the embodiments of the present invention, not all of them.

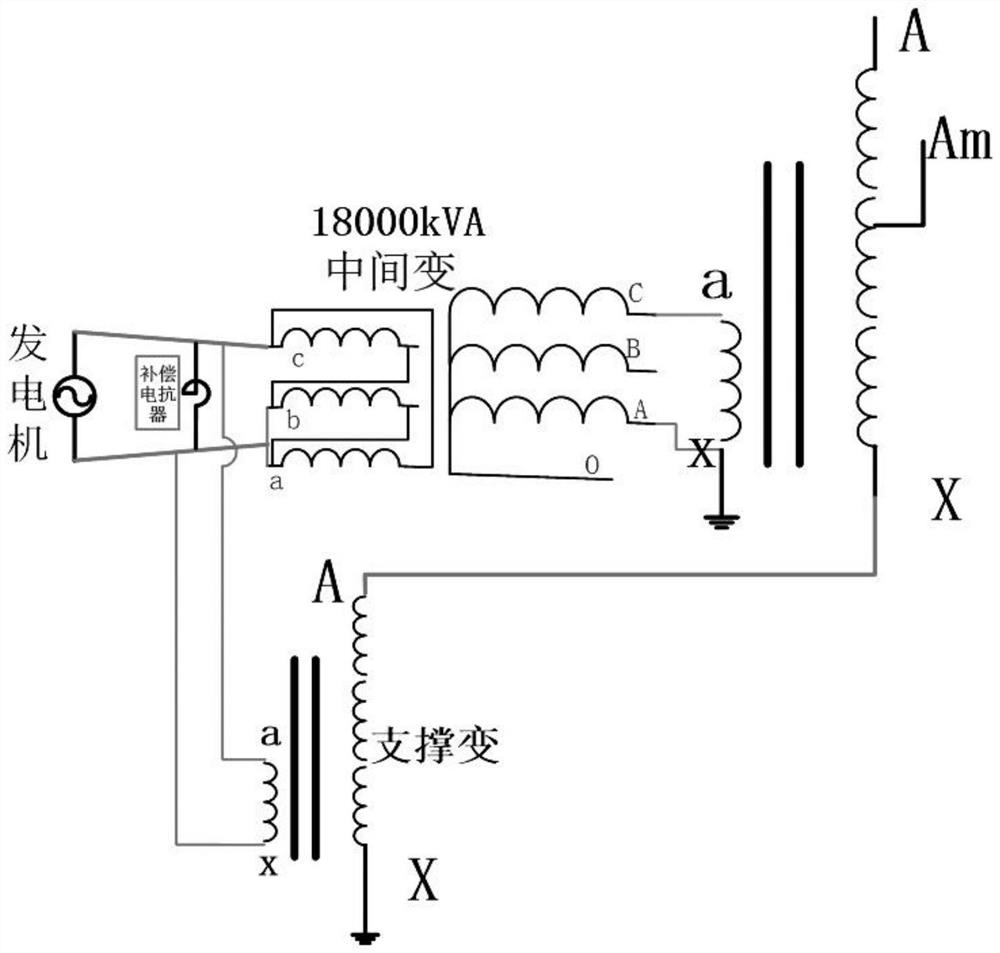

[0015] Such as figure 1 Shown is a schematic diagram of the electrical principle of the existing single-phase autotransformer line-side AC induction withstand voltage test. The test system includes: single-phase autotransformer under test, support transformer, 18000kVA intermediate transformer and compensating reactor, and the generator provides power supply for the whole test system.

[0016] When the single-phase autotransformer is subjected to the line-end AC induction withstand voltage test, in order to achieve the purpose of the test, the voltage at the head end of the transformer that needs to be assessed reaches the assessment voltage, and the inter-turn voltage of the winding is within the withstand range of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com