Parameterization rapid modeling method for profile radiator with taper corrugated fins

A technology of corrugated fins and modeling methods, which is applied in the field of parametric rapid modeling of radiators with tapered corrugated fin profiles, can solve the problems of complex modeling, heavy workload, and low efficiency of simulation analysis, so as to improve efficiency, The effect of improving simulation analysis efficiency and saving simulation modeling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0166] A parametric rapid modeling method for a tapered corrugated-fin profile radiator. The corrugated-fin profile radiator includes a fin part and a base plate part. The fin part includes intermediate fins and edge fins. The corrugated-fin profile radiator The structural feature expression is: y=f(φ(i),φ(j),φ(k)) ; in the expression φ(i) is the functional relation of the middle fin, φ(j) is the functional relation of the substrate part, φ(k) As the functional relationship of the edge fin, the construction of the corrugated fin profile radiator model includes the following steps:

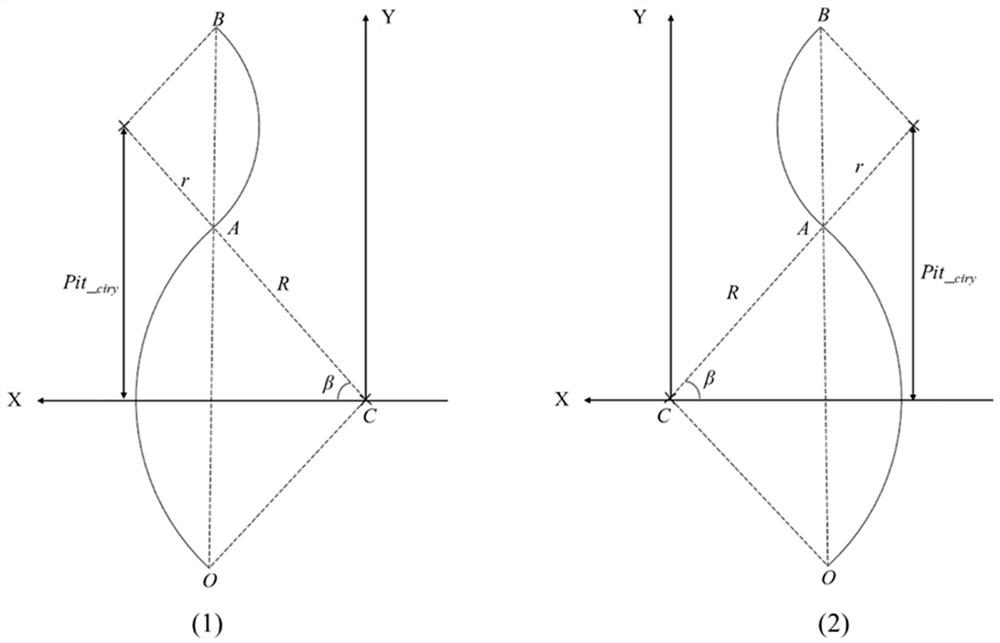

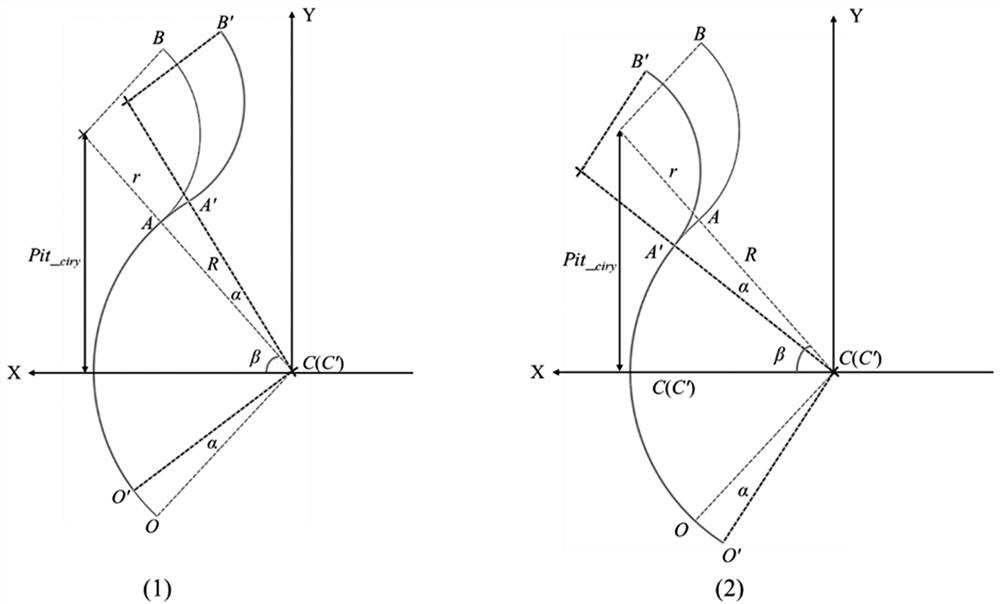

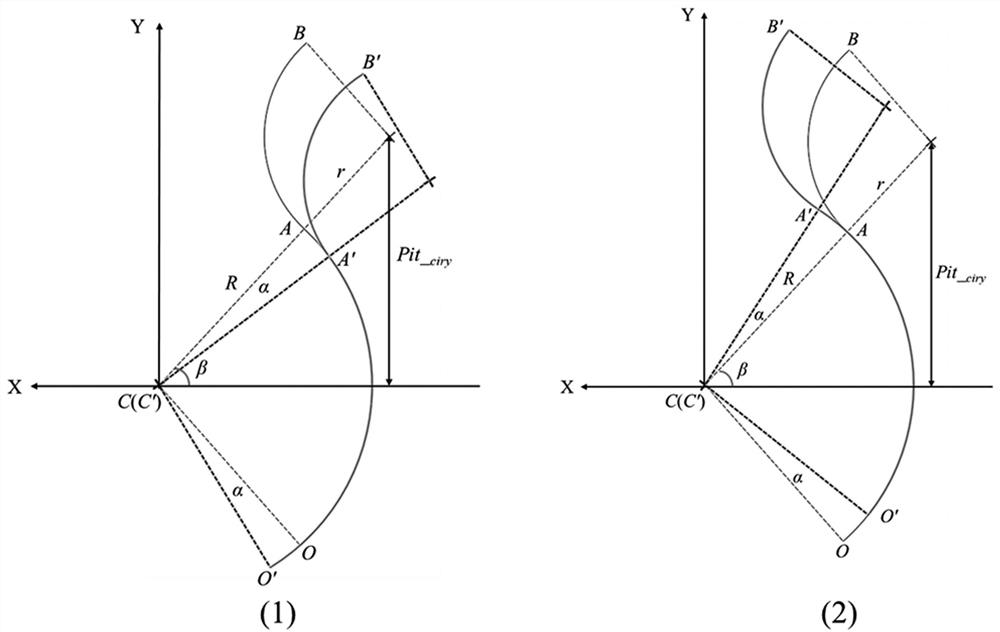

[0167] Step 1. Establish a single corrugated fin unit model. The large circle radius, small circle radius, offset distance of the center of the big and small circles in the ordinate direction, cycle period and cone angle of the corrugated fin unit are respectively R , r , Pit_ ciry , n and α , first define the coordinate system, the positive direction of the x-axis of the abscissa is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com