Peeling device capable of conveniently recycling residual materials

A peeling device and residual material technology, applied in the direction of circuits, electrical components, etc., can solve the problems of synchronous crushing and processing, and achieve the effect of simple structure, good user experience and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

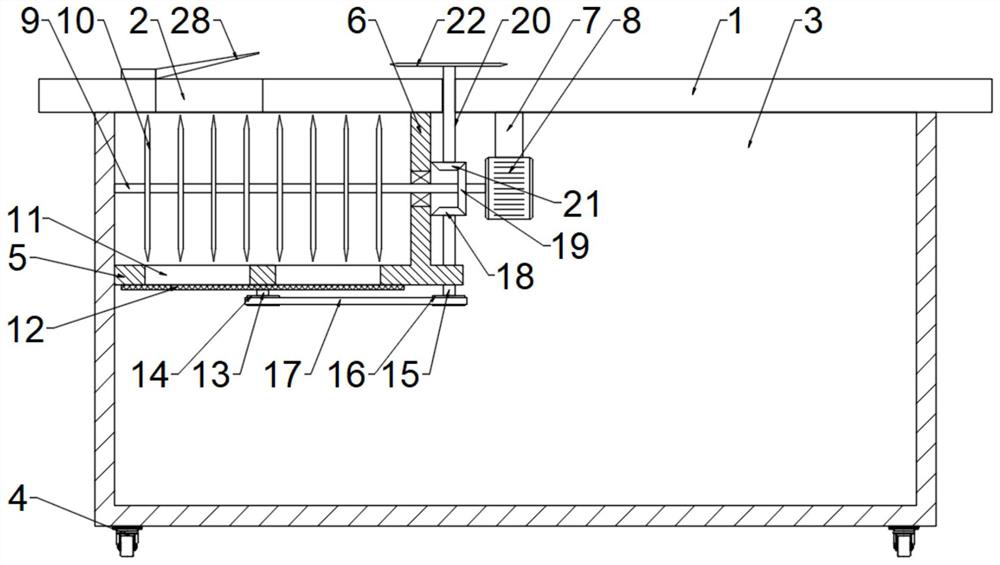

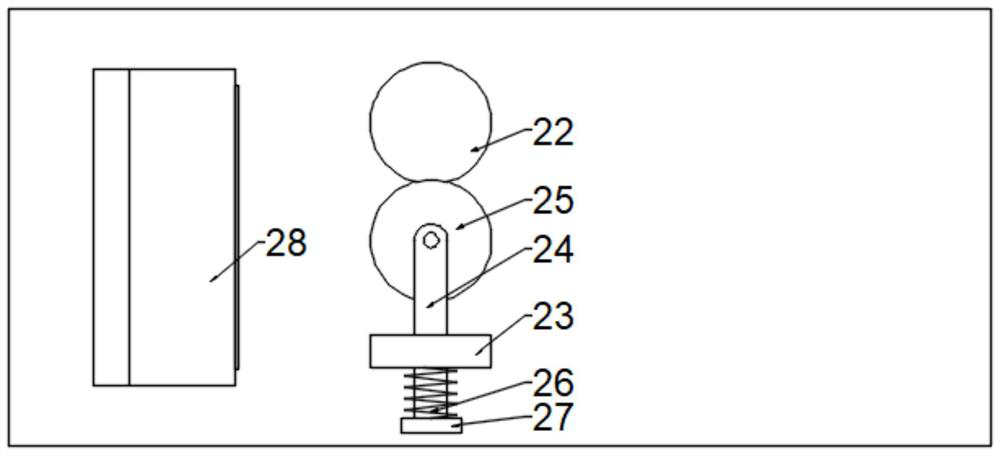

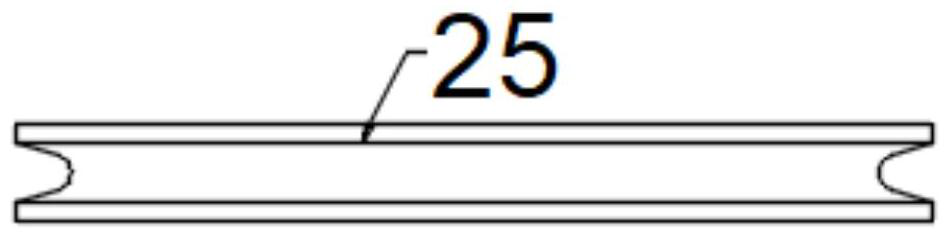

[0025] Example 1: Please refer to Figure 1-3 , a peeling device for convenient recovery of residual materials, comprising a horizontal fixed plate 1, a lowering hole 2 is provided on the horizontal fixed plate 1, a collecting box 3 is fixedly connected to the bottom of the horizontal fixed plate 1, and a collecting box 3 is fixedly connected to the bottom of the collecting box 3 The support assembly 4, the left side of the collection box 3 is fixedly connected with a horizontal partition 5, the front and rear ends of the horizontal partition 5 are fixedly connected with the collection box 3, and the upper right side of the horizontal partition 5 is fixedly connected with a longitudinal partition 6 , the front and rear ends of the longitudinal partition 6 are fixedly connected with the collecting box 3;

[0026] The middle part below the horizontal fixed plate 1 is fixedly connected with a motor bracket 7, the bottom of the motor bracket 7 is fixedly connected with a drive mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com