Crushing device for textile raw material production and processing

A crushing device and raw material technology, which is applied in the direction of grain processing, etc., can solve the problems of uniform crushing and processing operation influence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

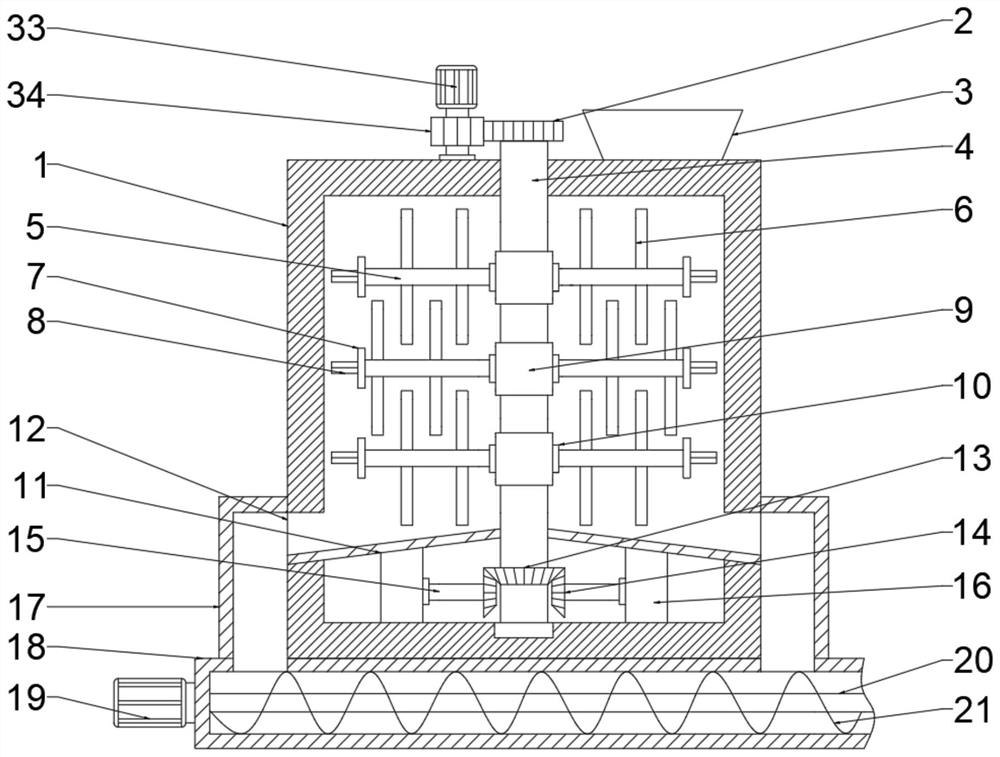

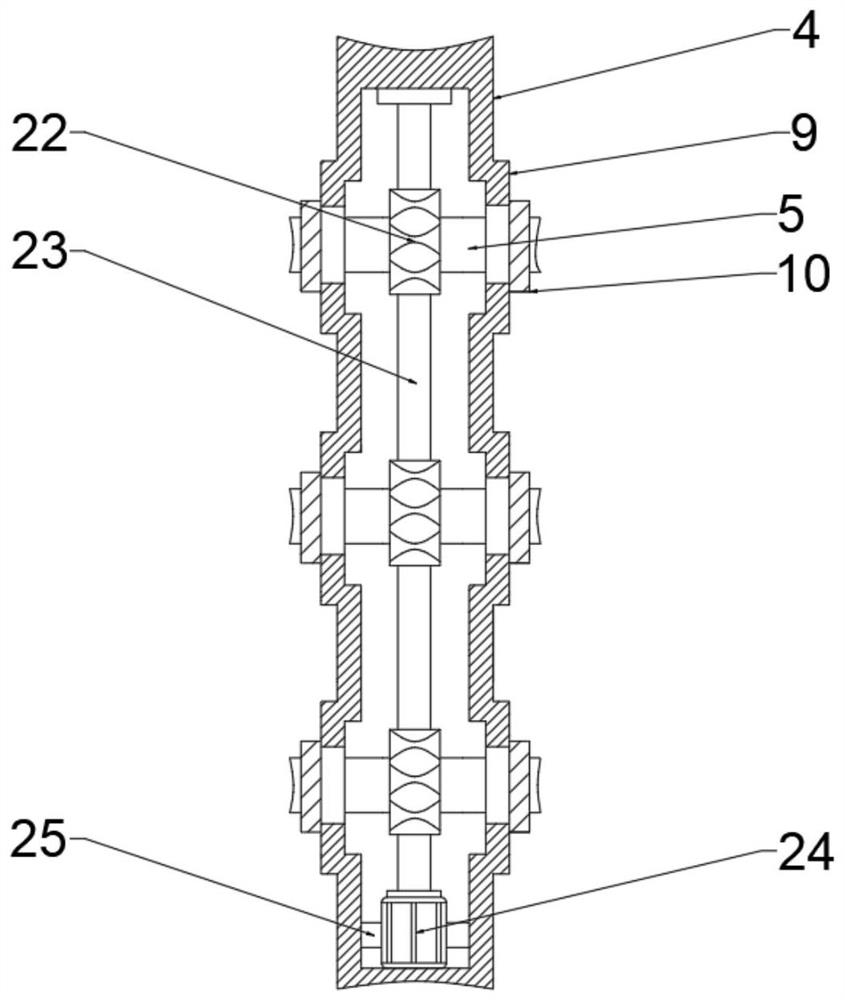

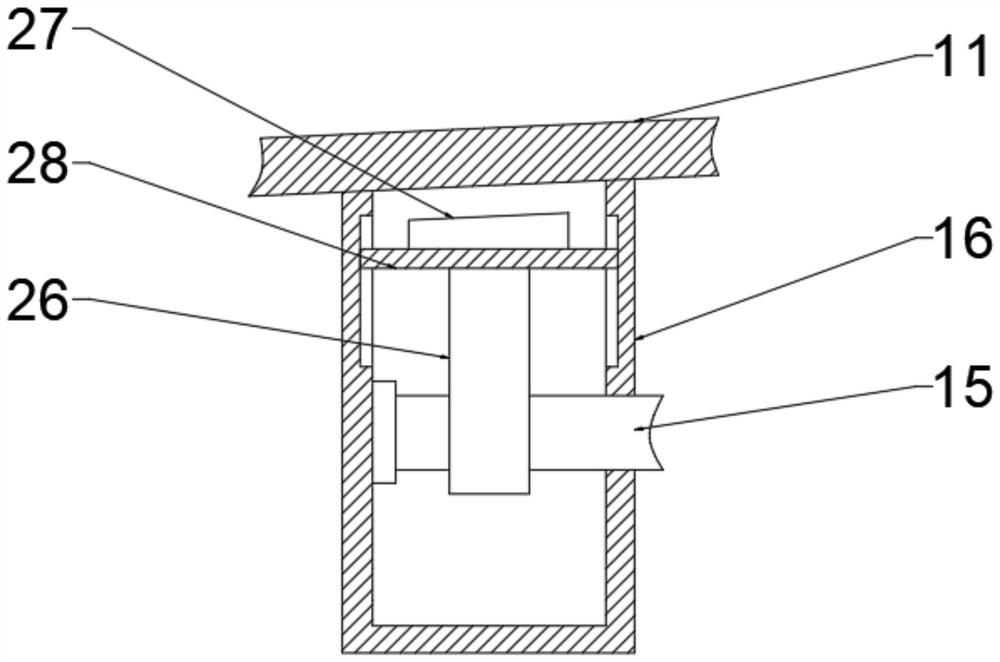

[0028] see Figure 1~6 , in the embodiment 1 of the present invention, a kind of crushing device for the production and processing of textile raw materials, comprising a first body 1, the top of the first body 1 is provided with a feed port 3 for feeding, the first body 1 The inner rotation is provided with a main shaft 4, the main shaft 4 is provided with a plurality of slave shafts 5, the middle part of the slave shaft 5 is rotatably set in the main shaft 4 through the installation sleeve 9, and the slave shaft 5 is set on the main shaft 5. The part outside the rotating shaft 4 is provided with a plurality of crushing blades 6 for crushing raw materials; the bottom sides of the first body 1 are provided with a blanking plate 11 obliquely for blanking, and the bottom of the blanking plate 11 is A vibrating mechanism is provided, and the lower end of the blanking plate 11 communicates with the blanking port 12, and the blanking port 12 is connected with a transmission part, an...

Embodiment 2

[0035] see Figure 1~6 , the transfer part includes a material guide bin 17, the upper end of the material guide bin 17 communicates with the discharge port 12, and the lower end of the material guide bin 17 communicates with the transfer bin 18, which is used to transfer the raw materials in the first machine body 1 Introduce in the transfer bin 18, the transfer bin 18 is arranged on the bottom of the first body 1, the transfer shaft 20 is arranged in the transfer bin 18, the auger 21 is arranged on the transfer shaft 20, the transfer bin 18 A first motor 19 is provided outside to drive the transmission shaft 20 to rotate. The outlet end of the transmission bin 18 communicates with the secondary crushing part, and the crushed raw materials are transported into the secondary crushing part through the transmission bin 18 .

[0036] Further, the secondary crushing part includes a second machine body 29, a screening chamber and a processing chamber are arranged in the second mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com