Electromagnetic relay capable of preventing arc short circuit

An electromagnetic relay and anti-arc technology, applied in the direction of electromagnetic relay, electromagnetic relay details, relay, etc., can solve problems such as explosion, easy arc entry, arc short circuit, etc., to achieve easy installation, good arc isolation effect, and low processing accuracy requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

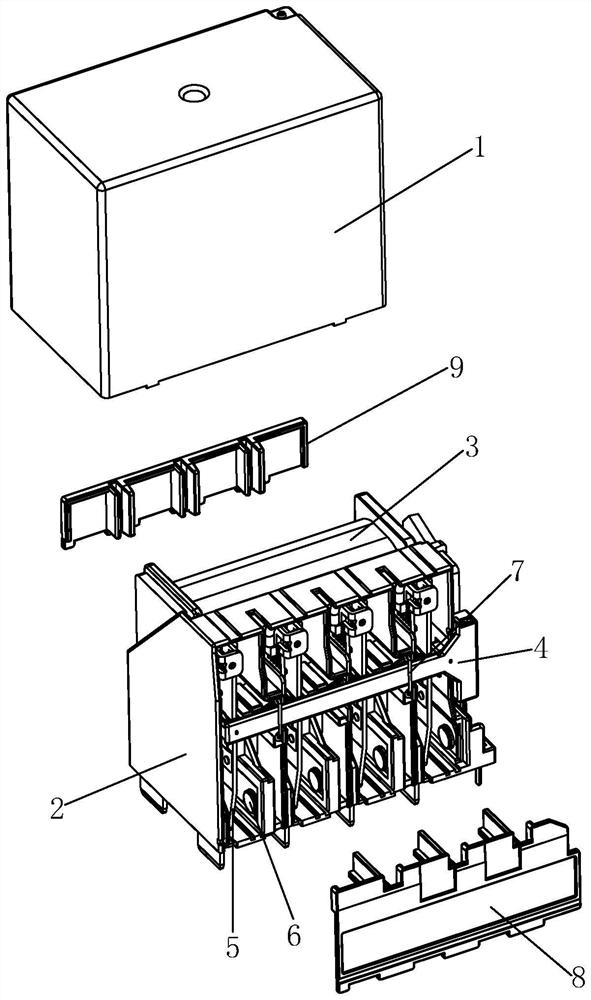

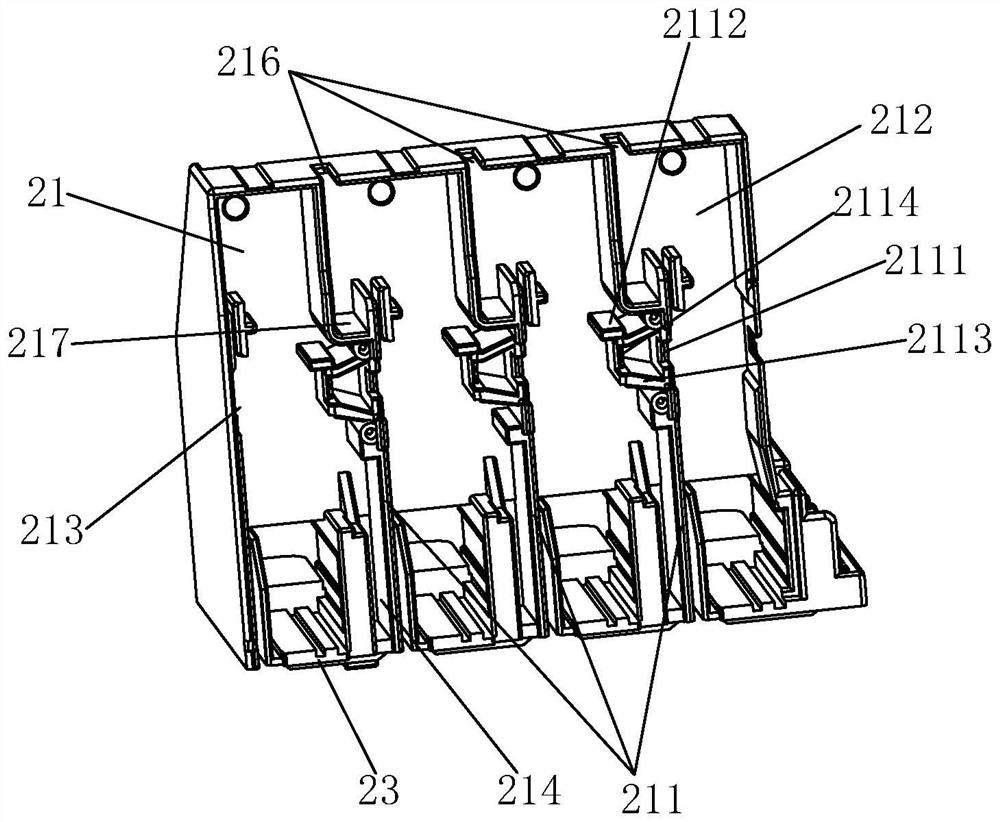

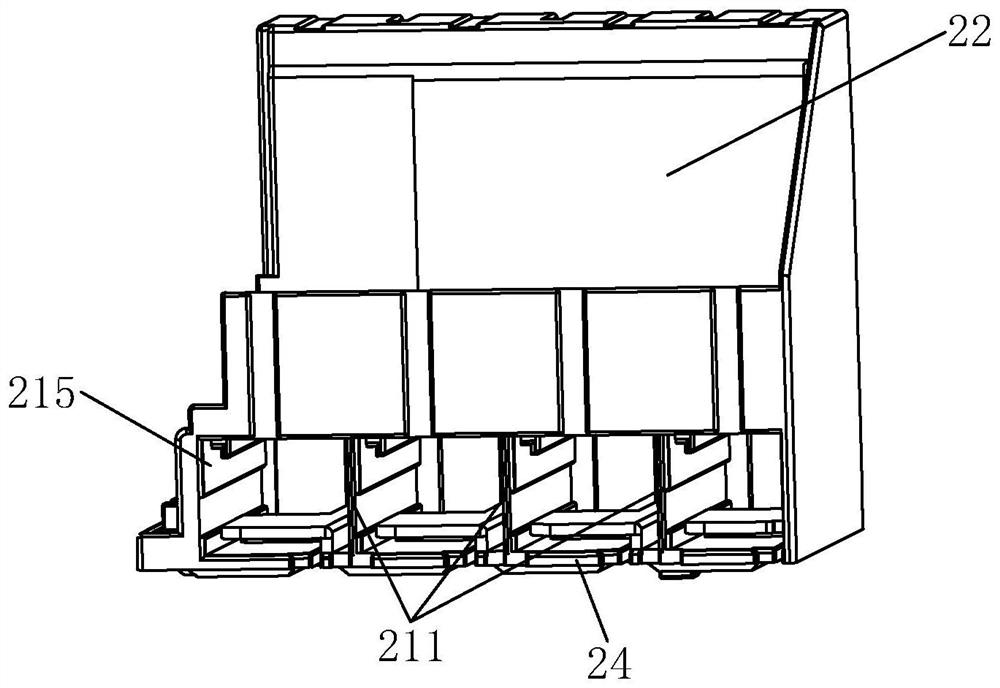

[0044] See Figure 1-Figure 20 As shown, an electromagnetic relay for preventing arc short circuit of the present invention includes a shell 1 with an open bottom, a base 2, a magnetic circuit part 3, a contact part and a push card 4, and the magnetic circuit part 3 is horizontally installed on the base 2 ; The base 2 is provided with a first accommodating cavity 21 of the contact part, and a plurality of partitions 211 are arranged in the first accommodating cavity 21 to divide the first accommodating cavity 21 into several compartments 212 distributed along a predetermined direction The side of the first accommodating cavity 21 is provided with a first opening 213 leading to each compartment 212; the contact part includes a number of contact units corresponding to the plurality of compartments 212, and each contact unit includes a moving spring component 5 and The static spring part 6, the moving spring part 5 and the static spring part 6 are installed in the corresponding c...

Embodiment 2

[0063] See Figure 21 , Figure 22 As shown, the electromagnetic relay for preventing arc short circuit of the present invention differs from the first embodiment above in that: the inner surface of the second arc shield 9 is also provided with a number of For vertical fourth baffles 94 , at least one fourth baffle 94 is inserted laterally into each compartment 212 . Specifically, two fourth baffles 94 are laterally inserted into each compartment 212 . The size of the fourth baffle 94 in the depth direction of the second opening 215 is greater than the size of the first baffle 91 in the depth direction of the second opening 215, and the fourth baffle 94 can be used to increase the dynamic The creepage distance between the spring part 5 and the static spring part 6 improves the insulation of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com