Feeding liquid for heating cigarette, preparation method of feeding liquid and heating cigarette

A cigarette and feed liquid technology, which is applied in the heating cigarette feed liquid and its preparation, and in the field of heating cigarettes, can solve the problems of unsatisfactory flavoring effect of tobacco extracts, waste of tobacco leaf resources, and increase of production costs, so as to reduce the blending test link , The effect of low difficulty in fragrance adjustment and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Embodiments of the present invention provide a method for preparing a feed liquid for heating cigarettes, which includes the following steps:

[0035] a), determine the leaf group of the heated cigarette;

[0036] b), sequentially extracting its tobacco essential oil, tobacco dew and tobacco absolute from each tobacco leaf in the leaf group;

[0037] c), mixing the extracted tobacco essential oil, tobacco dew and tobacco absolute, to obtain the extract mixture of the tobacco leaf material;

[0038] d) Mixing the material extract mixture of each tobacco leaf in the leaf group according to the ratio of the leaf group to obtain the feed liquid.

[0039] In the preparation method of the feed liquid provided in this embodiment, the first step is to determine the leaf group of the heated cigarette. The feeding liquid for heating cigarettes provided in the embodiments of the present invention has different raw materials and proportions for different brands of heating cigaret...

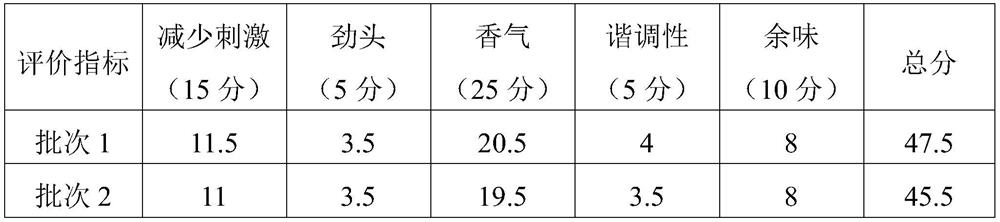

Embodiment 1

[0063] 1. Determine the leaf group formula of a certain brand of heated cigarette as follows: No. 1 tobacco leaf material: No. 2 tobacco leaf material: No. 3 tobacco leaf material: No. 4 tobacco leaf material: No. 5 tobacco leaf material = 1:1:2:2:3;

[0064] 2. Extract tobacco essential oil, tobacco dew and tobacco absolute from each tobacco leaf material in the following manner:

[0065] Dry the tobacco material at 45°C and crush it into 40-mesh tobacco powder for later use; weigh 200g of tobacco powder and 2000mL of deionized water into a 5L flask, and place it in an ultrasonic device for ultrasonic treatment at a temperature of 40°C. The frequency is 20kHz, and the ultrasonic time is 50min; after the ultrasonic is finished, put the flask into a steam distillation device, add 100g of sodium chloride, heat and reflux for 3h, and collect the tobacco essential oil after the reflux; Add 20mL of n-hexane for extraction, then concentrate the extract under reduced pressure at 40°C...

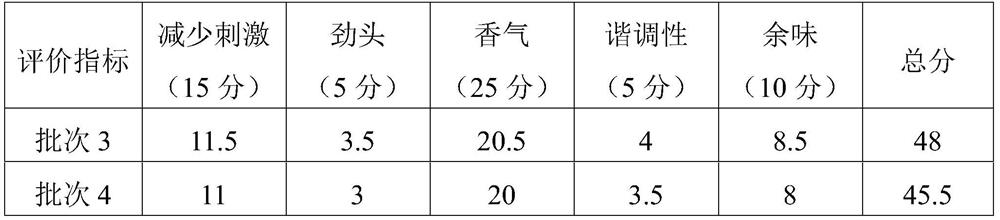

Embodiment 2

[0069] 1. Determine the leaf group formula of a heated cigarette of a certain brand, such as: tobacco leaf material A: tobacco leaf material B: tobacco leaf material C: tobacco leaf material D: tobacco leaf material E: tobacco leaf material F=1:2:3:2:2:1;

[0070] 2. Extract tobacco essential oil, tobacco dew and tobacco absolute from each tobacco leaf material in the following manner:

[0071] Dry the tobacco material at 60°C and crush it into 20-mesh tobacco powder for later use; weigh 300g of tobacco powder and 3000mL of deionized water into a 5L flask, place it in an ultrasonic device for ultrasonic treatment, the temperature is 60°C, and the frequency The ultrasonic time is 30kHz, and the ultrasonic time is 10min; after the ultrasonic is finished, put the flask into a steam distillation device, heat 150g of sodium chloride, and heat to reflux for 5h. 30mL of n-hexane for extraction, and then the extract was concentrated under reduced pressure at 60°C and 0.05Mpa to remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com