Automatic sand discharging and removing device for shale gas well

A technology for shale gas wells and de-sanders, which is used in wellbore/well components, production fluids, and earth-moving drilling, etc., can solve the problems of wasting manpower, sand cannot be removed in time, and the life of sand discharge control valves is short, etc. Longevity, manpower saving, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

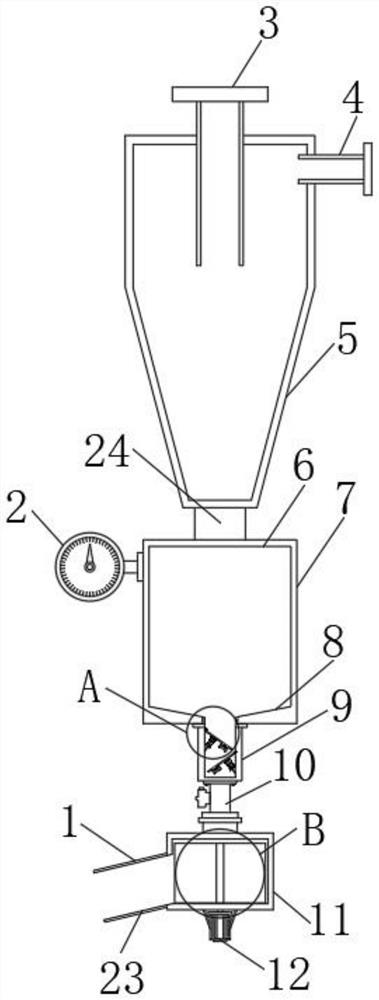

[0033] An automatic desand removal device for shale gas wells, including a separation component, a sand outlet, a water outlet and a feed end are installed on the separation component, the feed end is used for inputting a mixture of water, gas and sand particles, and the separation component is used for Separate the mixture of water vapor and sand particles, so that the mixture of water vapor and sand particles is separated into water vapor and sand particles, the water outlet end is used to discharge water vapor, and the sand outlet end is used to discharge sand particles;

[0034] A valve assembly is installed at the outlet of the sand discharge end, and a detection assembly is installed on the sand discharge end. When the height of the sand surface inside the sand discharge end reaches the maximum height of the detection assembly, the detection assembly triggers the valve assembly, the valve assembly opens, and the sand discharge end When the sand is discharged, when the hei...

Embodiment 2

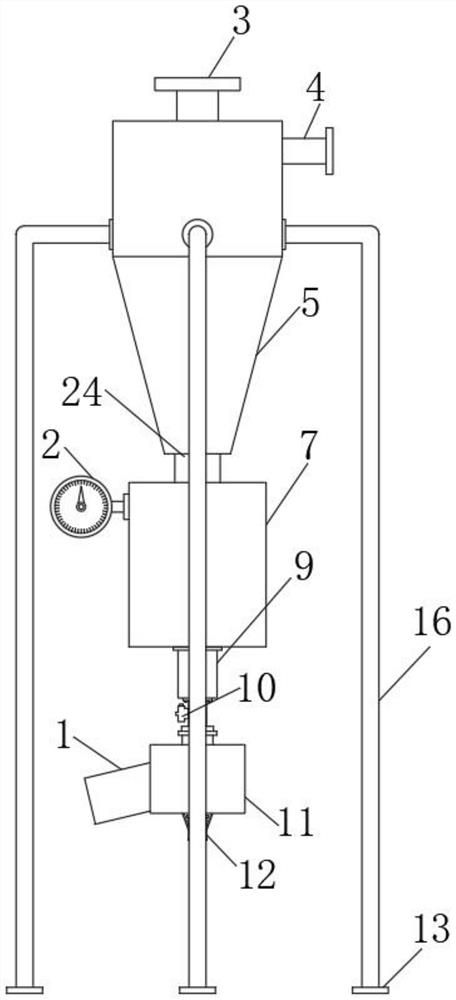

[0037] An automatic desand removal device for shale gas wells, including a separation component, a sand outlet, a water outlet and a feed end are installed on the separation component, the feed end is used for inputting a mixture of water, gas and sand particles, and the separation component is used for Separate the mixture of water vapor and sand particles, so that the mixture of water vapor and sand particles is separated into water vapor and sand particles, the water outlet end is used to discharge water vapor, and the sand outlet end is used to discharge sand particles;

[0038] A valve assembly is installed at the outlet of the sand discharge end, and a detection assembly is installed on the sand discharge end. When the height of the sand surface inside the sand discharge end reaches the maximum height of the detection assembly, the detection assembly triggers the valve assembly, the valve assembly opens, and the sand discharge end When the sand is discharged, when the hei...

Embodiment 3

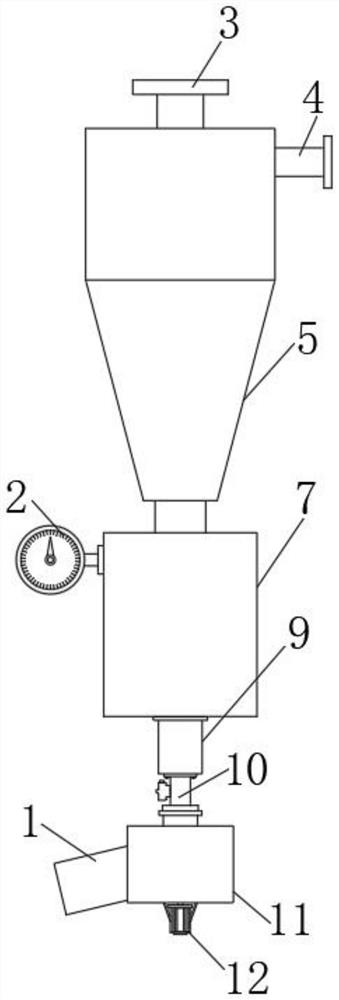

[0043] An automatic desand removal device for shale gas wells, including a separation component, a sand outlet, a water outlet and a feed end are installed on the separation component, the feed end is used for inputting a mixture of water, gas and sand particles, and the separation component is used for Separate the mixture of water vapor and sand particles, so that the mixture of water vapor and sand particles is separated into water vapor and sand particles, the water outlet end is used to discharge water vapor, and the sand outlet end is used to discharge sand particles;

[0044] A valve assembly is installed at the outlet of the sand discharge end, and a detection assembly is installed on the sand discharge end. When the height of the sand surface inside the sand discharge end reaches the maximum height of the detection assembly, the detection assembly triggers the valve assembly, the valve assembly opens, and the sand discharge end When the sand is discharged, when the hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com