Cold box pre-cooling equipment for natural gas liquefaction in chemical industry

A natural gas and cold box technology, applied in liquefaction, mechanical equipment, refrigeration and liquefaction, etc., can solve the problems of not collecting excess hot gas, environmental pollution, etc., to avoid affecting the environment and avoiding blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

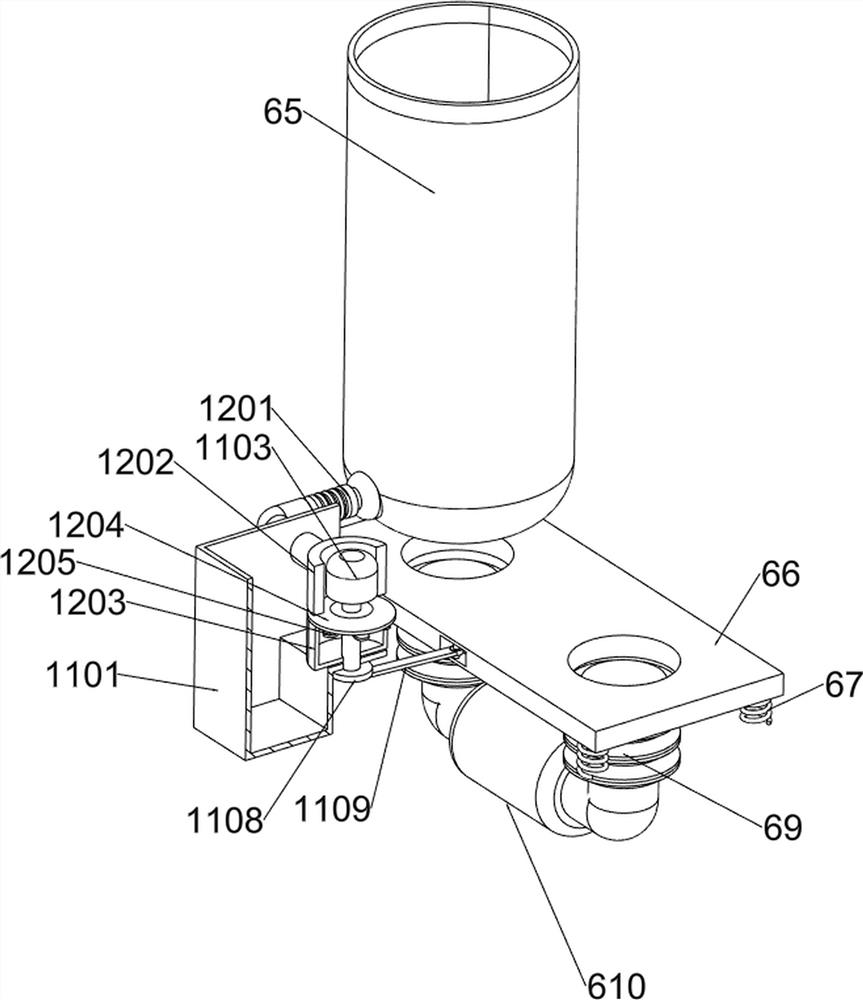

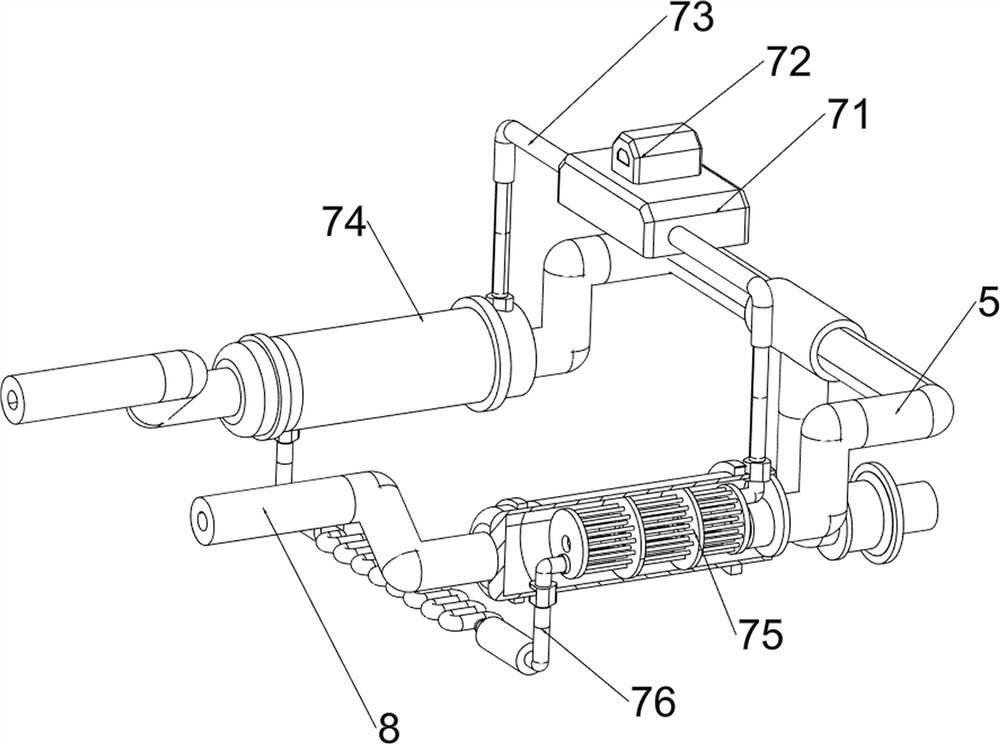

[0090] A cold box precooling equipment for chemical natural gas liquefaction, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 9 , Figure 14 and Figure 15 As shown, it includes a cold box 1, an intake pipe 2, a mounting base 3, a compressor 4, a first pipeline 5, a filter mechanism 6, a heat exchange mechanism 7, a first exhaust pipe 8 and a water cooling mechanism 10, and the left side of the cold box 1 The lower part of the side is connected with the intake pipe 2, the left side of the cold box 1 is connected with the mounting base 3, the intake pipe 2 is connected with the bottom of the mounting base 3, the right side of the mounting base 3 is connected with the compressor 4, and the right side of the compressor 4 is connected with the first Pipeline 5, filter mechanism 6 is provided on the lower left side of cold box 1, heat exchange mechanism 7 is arranged on the first pipeline 5, first exhaust pipe 8 is connected...

Embodiment 2

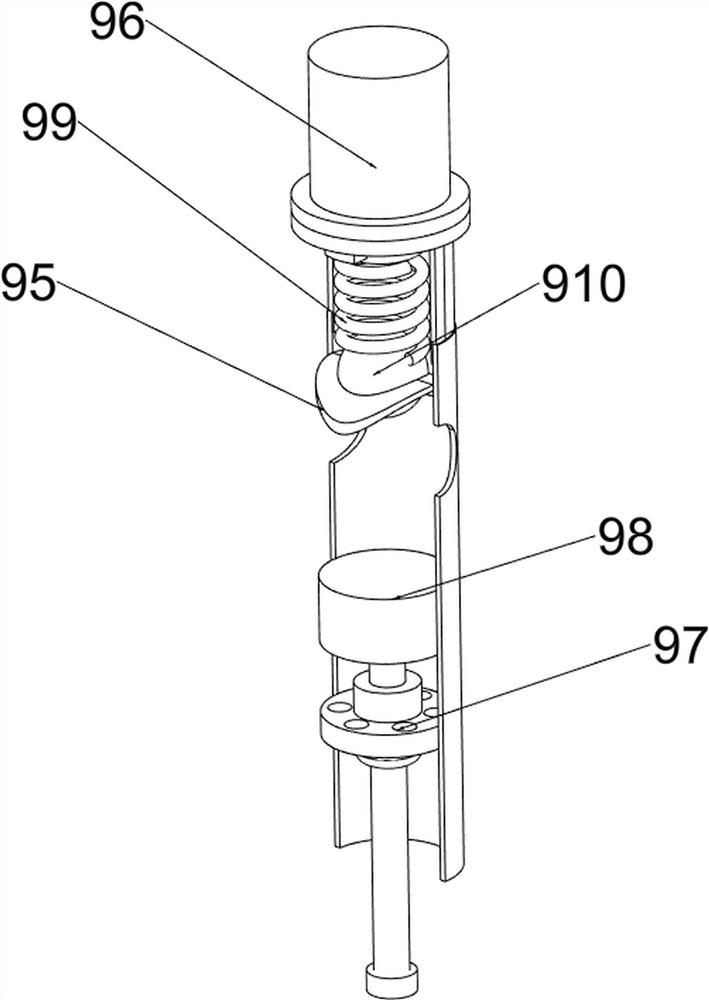

[0096] On the basis of Example 1, such as image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 10 , Figure 11 , Figure 12 and Figure 13 As shown, a refrigeration mechanism 9 is also included, and the refrigeration mechanism 9 includes a pressure vessel 91, a third pipeline 92, a condensation pipeline 93, a liquid nitrogen container 94, a fourth pipeline 95, a refrigeration pipeline 96, a first fixed block 97, a push block 98. The fourth spring 99 and the blocking block 910. A pressure vessel 91 is installed on the outside of the circulation pipe 76. The middle part on the right side of the pressure vessel 91 is connected to a third pipeline 92. The left side of the third pipeline 92 is connected to a condensation pipeline 93. The bottom of the condensation pipeline 93 The end is connected to the top of the pressure vessel 91, the top of the third pipeline 92 is connected to the fourth pipeline 95, the top of the third pipeline 92 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com