Method for measuring servo current in real time during moudling loading of electromechanical servo mechanism

A technology of electromechanical servo and servo current, applied in the field of simulation test of electromechanical servo mechanism model flight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

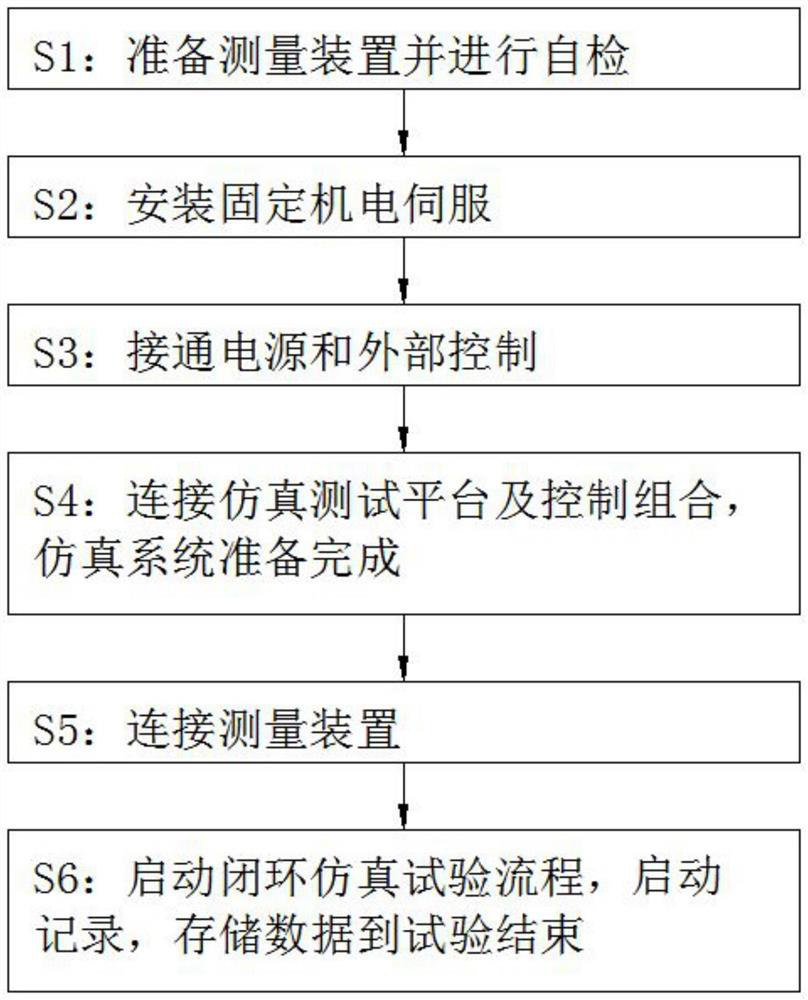

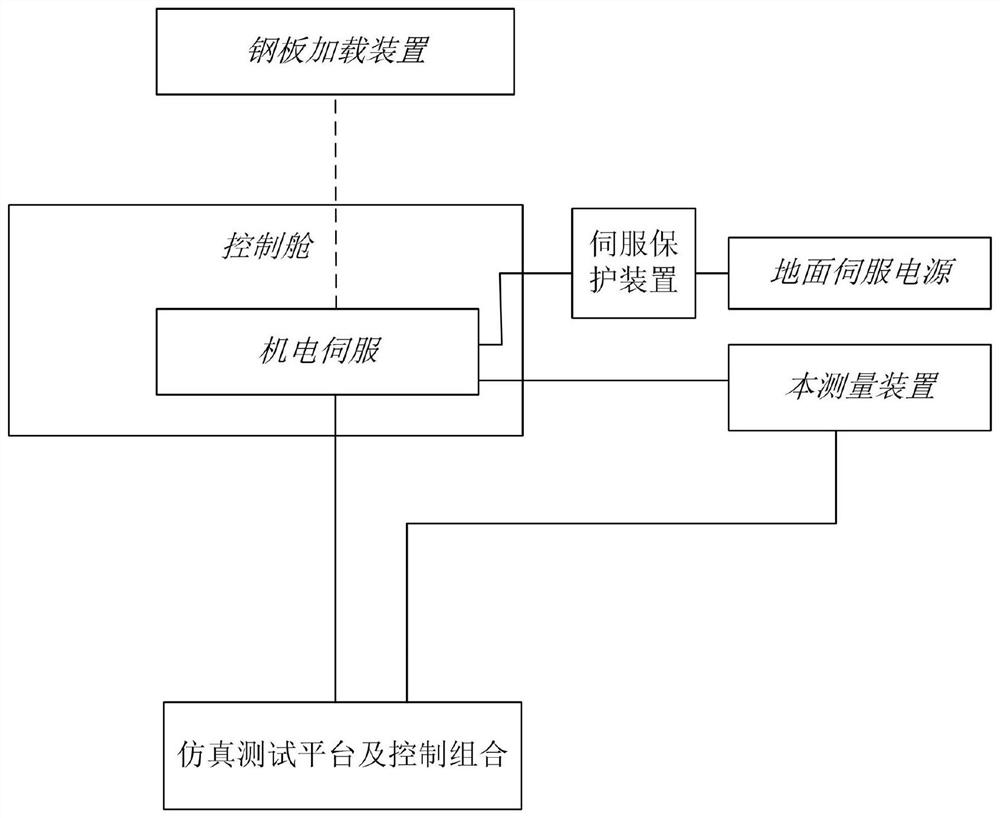

[0037] refer to Figure 1-2 , a method for real-time measurement of servo current when an electromechanical servo mechanism is loaded, comprising the following steps:

[0038] S1: Prepare the measuring device and conduct self-inspection, in order to ensure that there will be no sudden failure during use;

[0039] Measuring devices include control cabin, simulation test platform and control combination, electromechanical servo, servo protection device, steel plate loading device, ground servo power supply, cable and current measuring device;

[0040] In this embodiment, the control cabin is used to provide a more realistic environment for the electromechanical servo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com